The final stage of cowboy boot manufacturing is a meticulous blend of aesthetic refinement and rigorous quality assurance. Before a boot is boxed, it undergoes conditioning, polishing, and a detailed hand-inspection that scrutinizes everything from the stitching to the structural integrity of its construction.

This final quality control is not merely about making the boot look presentable; it is the critical step that validates the boot's durability, comfort, and craftsmanship, ensuring the finished product lives up to its promise.

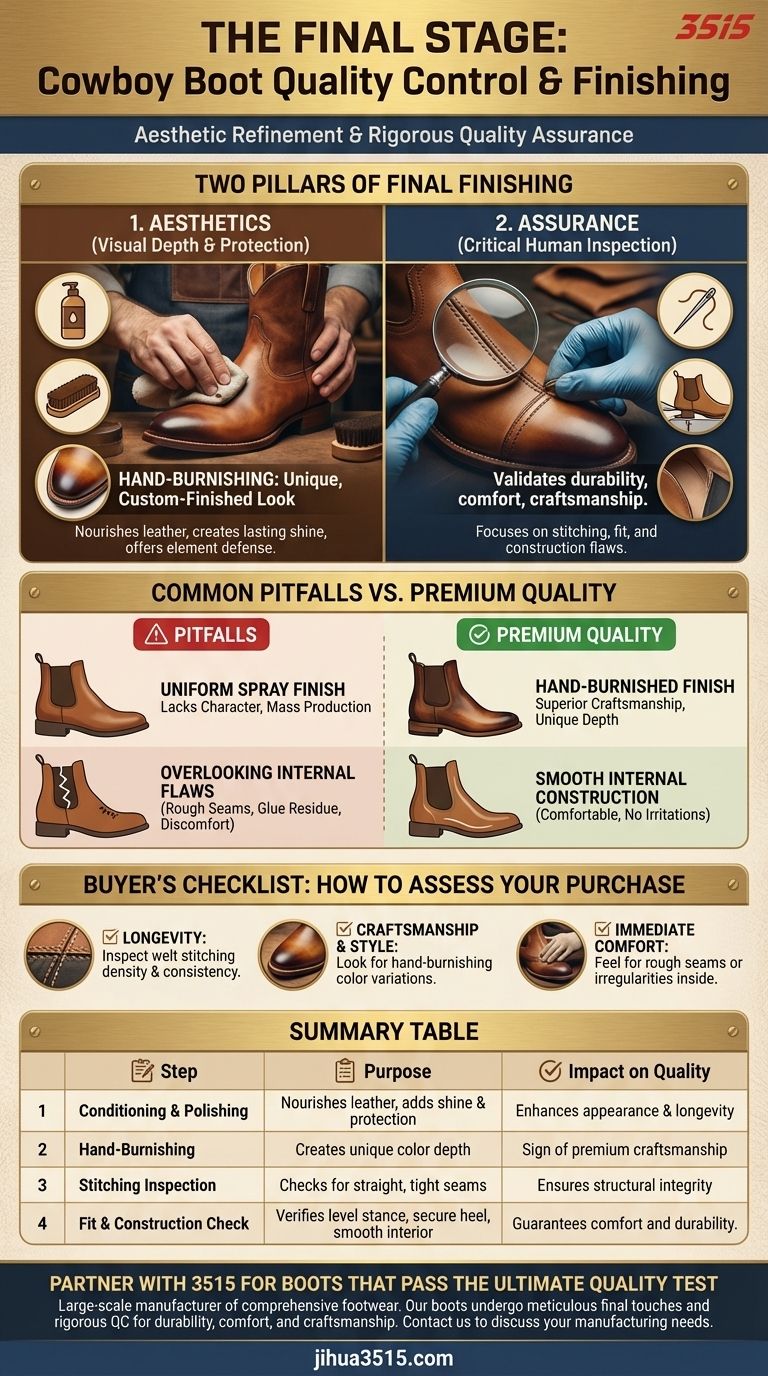

The Two Pillars of Final Finishing: Aesthetics and Assurance

The last steps in a boot's journey from raw materials to a finished product can be divided into two essential functions. The first is enhancing the leather's appearance and providing initial protection. The second is a non-negotiable inspection to catch any flaw that could compromise the boot's performance or lifespan.

Achieving Visual Depth and Protection

After assembly, the leather can be dry and uniform in appearance. The finishing process brings it to life.

Craftsmen apply conditioners to nourish the leather, followed by polishes and creams to create a lasting shine and offer a first line of defense against the elements.

For higher-end boots, this stage often includes hand-burnishing. This is a technique where artisans use friction and heat to create darker, richer tones on specific areas like the toe and heel, giving each pair a unique, custom-finished look.

The Critical Role of Human Inspection

This is where true quality is confirmed. An experienced inspector meticulously examines each boot, focusing on key failure points.

The inspection covers all stitching. Lines must be straight, tension must be consistent, and there can be no loose or broken threads, especially along the welt where the sole attaches to the upper.

They also check for fit and construction flaws. This involves ensuring the boot stands level, the heel is secure, and the internal seams are smooth to prevent irritation. Any imperfection in the leather or error in construction is flagged at this stage.

Common Pitfalls and What They Reveal

The difference between a premium boot and a mass-market one often becomes clear during these final touches. Understanding these differences allows you to spot true quality.

Overlooking Internal Flaws

A common shortcut is focusing only on the boot's exterior shine while ignoring the interior. A quality inspection ensures the inside is free of rough seams, glue residue, or protruding nails that could cause discomfort.

The Uniform vs. Unique Finish

In mass production, a uniform, sprayed-on finish is often used for efficiency. While consistent, it lacks the character and depth of a hand-burnished boot, which is a hallmark of superior craftsmanship and attention to detail.

How to Apply This to Your Purchase

When you are assessing a pair of boots, you can perform your own version of this final quality check.

- If your primary focus is longevity: Inspect the welt stitching where the sole meets the boot, ensuring it is dense, even, and consistent on both boots.

- If your primary focus is craftsmanship and style: Look for the subtle color variations and depth on the toe and heel that indicate hand-burnishing.

- If your primary focus is immediate comfort: Run your hand inside the boot to feel for any rough seams, bumps, or irregularities that could cause issues later.

Understanding these final details empowers you to look past the surface shine and assess the true quality and craftsmanship of any cowboy boot.

Summary Table:

| Final Touches & QC Step | Purpose | Impact on Quality |

|---|---|---|

| Conditioning & Polishing | Nourishes leather, adds shine & protection | Enhances appearance & longevity |

| Hand-Burnishing | Creates unique color depth on toe/heel | Sign of premium craftsmanship |

| Stitching Inspection | Checks for straight, tight, consistent seams | Ensures structural integrity |

| Fit & Construction Check | Verifies level stance, secure heel, smooth interior | Guarantees comfort and durability |

Partner with 3515 for Boots That Pass the Ultimate Quality Test

As a large-scale manufacturer, 3515 produces a comprehensive range of footwear for distributors, brand owners, and bulk clients. Our production capabilities encompass all types of shoes and boots, including cowboy boots that undergo the meticulous final touches and rigorous quality control detailed above. We ensure every pair meets the highest standards of durability, comfort, and craftsmanship.

Ready to offer your customers boots built to last? Contact 3515 today to discuss your manufacturing needs and discover how our expertise can become your competitive advantage.

Visual Guide

Related Products

- Wholesale Anti-Smash & Puncture-Proof Safety Shoes Custom Manufacturing for Brands

- Premium KPU Injection Athletic Style Safety Shoes

- Premium High-Cut Waterproof Safety Boots Manufacturing & Wholesale Solutions

- Premium Wholesale Waterproof Safety Boots High Performance Protection for Industrial Markets

- Premium Grain Leather Safety Boots for Bulk Supply

People Also Ask

- What are some recommended shoe styles for business casual attire? Master the Professional Look

- How can business casual footwear be adapted for different seasons? Master Material Selection for Year-Round Style

- How should bit loafers be styled for a business casual outfit? A Guide to Polished Versatility

- What is the legacy of the Desert Boot? From Military Necessity to Timeless Style Icon

- What are some business casual outfit ideas with chukka boots? Master the Versatile Look

- How do Chelsea Boots differ from Chukka Boots? A Guide to Style & Fit

- What are the recommended colors for chukka boots? A Guide to Versatile Style

- What are the best shoes for daily use? Find Your Perfect Match for All-Day Comfort