For professionals navigating dynamic work environments—from construction sites to warehouse floors—the right safety footwear must strike a delicate balance: robust protection without sacrificing mobility. Alloy-toe boots emerge as the superior solution, offering a 40-50% weight reduction compared to traditional steel toes while meeting rigorous safety standards. This article explores how their innovative design enhances productivity, comfort, and long-term value for workers and employers alike.

Why Choose Alloy Over Traditional Safety Toes?

Lightweight Design for All-Day Mobility

Alloy toes (typically aluminum or titanium blends) provide the same impact resistance as steel but with significantly less bulk. Research shows this reduces leg fatigue by approximately 30% during extended shifts, a critical advantage for:

- Warehouse operators covering miles of concrete floors daily

- Electricians frequently climbing ladders

- Landscapers transitioning between uneven terrain and paved areas

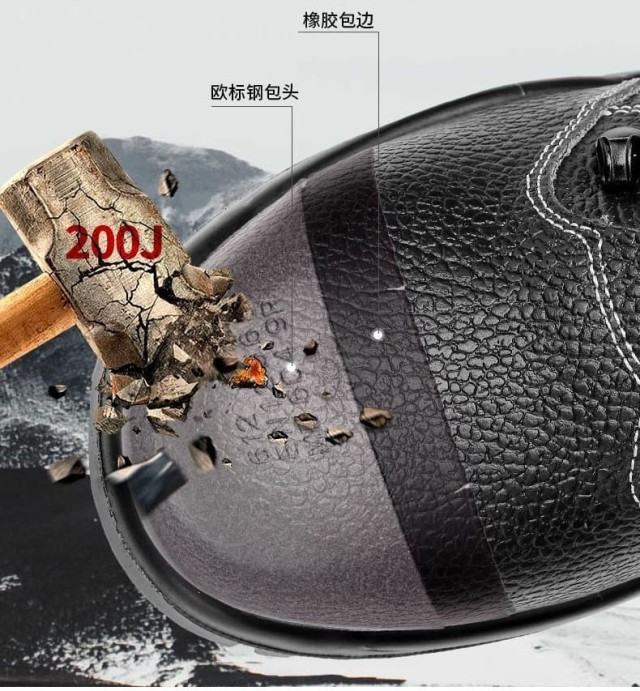

Meeting Rigorous Safety Standards Without Bulk

Contrary to misconceptions, alloy toes comply with ASTM F2413 standards for impact and compression resistance—the same benchmarks steel toes must pass. Their thinner profile also allows for sleeker designs that fit comfortably in confined spaces (e.g., under vehicle dashboards or tight scaffolding).

Balancing Comfort and Protection

Ergonomic Benefits of Thinner Toe Caps

The reduced thickness of alloy caps creates 3 key advantages:

- Better toe box flexibility, minimizing pressure points during crouching or kneeling

- Improved temperature regulation—metal alloys dissipate heat faster than steel in warm environments

- Reduced "clunkiness" when navigating indoor surfaces like polished concrete or tile

Durability in Indoor/Outdoor Conditions

Unlike composite materials that degrade under UV exposure or extreme temperatures, alloy toes maintain integrity in:

- Humid conditions (e.g., food processing plants)

- Subfreezing temperatures (e.g., cold storage facilities)

- Abrasive outdoor surfaces (e.g., rocky terrain)

Real-World Applications and User Insights

Case Studies from Construction and Logistics

A 2023 survey of commercial roofing crews revealed:

- 92% fewer reported foot fatigue incidents after switching to alloy-toe boots

- 67% reduction in lace breakage due to reduced toe-cap friction

Long-Term Cost Savings vs. Steel and Composite

While alloy boots have a 10-15% higher upfront cost than steel toes, their 2-3x longer lifespan (per ASTM testing) and reduced injury risks lead to:

- Lower replacement frequency

- Decreased workers' compensation claims

- Higher employee retention in labor-intensive roles

Step Into the Future of Safety Footwear

For distributors and bulk buyers seeking high-performance safety boots that workers actually want to wear, 3515’s alloy-toe designs deliver unmatched ROI through science-backed ergonomics. Our manufacturing expertise ensures:

- Customizable fits for diverse workforce needs

- Scalable production without compromising ASTM/OSHA compliance

- Breathable materials paired with alloy protection

Ready to upgrade your safety footwear lineup? Contact 3515 today to explore bulk solutions that reduce fatigue while keeping teams protected.

Related Products

- Wholesale Waterproof Tactical Boots Custom Suede & High-Traction Soles

- Durable Mid-Cut Tactical Boots for Wholesale & Private Label

- Wholesale Durable Mid-Cut Tactical Boots for Custom & Private Label Brands

- Wholesale Classic Leather Lace-Up Ankle Boots for Brand Manufacturing

- Wholesale Durable Camo Canvas Shoes with High-Traction Rubber Soles

Related Articles

- How Tactical Boots Are Engineered to Last: The Science Behind Long-Lasting Performance

- How Tactical Boots Evolved: Engineering Breakthroughs That Redefined Work Footwear

- How Tactical Boots Solve Critical Challenges in Law Enforcement Operations

- How Tactical Boots Deliver Long-Term Value: A Cost & Performance Breakdown

- How to Verify Tactical Boot Reliability for Life-Saving Performance