When lives depend on footwear, settling for substandard tactical boots isn’t an option. Whether you're procuring for law enforcement, military units, or security teams, identifying truly reliable providers requires scrutinizing material certifications, stress-testing methods, and hidden cost traps. This guide breaks down the critical evaluation criteria used by professionals to mitigate operational risks.

Critical Factors in Tactical Boot Reliability

Material Certifications for Threat Protection

Tactical boots must meet rigorous standards to defend against workplace hazards. Key certifications to verify:

- ASTM F2413-18 Compliance: Footwear must withstand approximately 270 pounds of force in puncture resistance tests, achieved through embedded steel or composite plates. This standard also covers impact/compression resistance and electrical hazard protection.

-

Upper Material Selection:

- Full-grain leather: Superior durability and water resistance, ideal for harsh environments.

- Ballistic nylon: Lightweight and tear-resistant, often paired with mesh for breathability in warm climates.

Providers should openly disclose material origins and testing documentation.

Stress-Testing Methodologies in Production

Reliable manufacturers simulate extreme conditions during development:

- Multi-Directional Flex Tests: Assess sole adhesion and seam integrity after thousands of motion cycles.

- Water Immersion Trials: Boots submerged for extended periods to check for leaks or material degradation.

- Abrasion Resistance Checks: Soles and uppers are subjected to surfaces like concrete and gravel to measure wear rates.

Ask providers for third-party lab reports validating these tests.

Hidden Risks of Provider Shortcuts

Case Study: Ankle Injuries from Poor Seam Construction

Agencies have reported higher ankle sprains in boots with single-stitched seams (versus double or triple stitching). Weak seams separate under lateral stress, destabilizing the wearer during pursuits or uneven terrain.

Financial Costs of Premature Boot Replacement

Low-cost boots often fail within 6–12 months, forcing frequent replacements. For a 100-person team, this can mean:

- $50,000+ annually in reinvestment (assuming mid-range boots at ~$150/pair).

- Training disruptions from acclimating to new footwear.

Law Enforcement Verification Protocols

Interpreting Third-Party Safety Certifications

Beyond ASTM standards, look for:

- NFPA 1999: Certifies protection against bloodborne pathogens for EMS personnel.

- EN ISO 20345: European equivalent to ASTM, with additional slip-resistance requirements.

Cross-Referencing Agency Procurement Standards

Top-tier departments publish detailed boot specifications. Compare provider claims against:

- Durability thresholds: Minimum 18-month lifespans for daily wear.

- Traction patterns: Deep lugs (at least 3–5mm) for mud/ice grip.

Trust Your Gear, Trust Your Provider

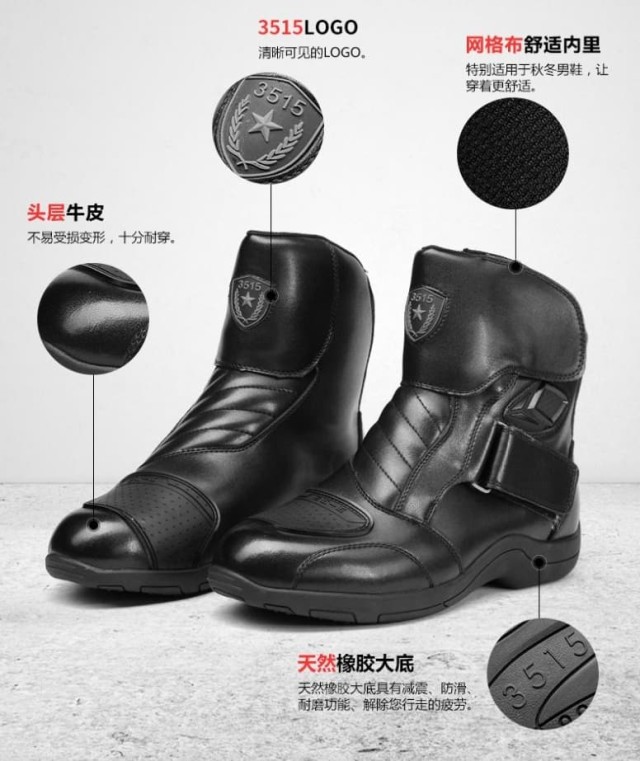

Reliable tactical boots blend certified materials, exhaustive testing, and transparent manufacturing. For agencies and distributors, partnering with an established producer like 3515 ensures access to battle-tested footwear engineered for real-world demands.

Ready to equip your team with boots that won’t fail? Contact 3515 to discuss scalable solutions tailored to your operational needs.

Related Products

- Wholesale Durable Mid-Cut Tactical Boots for Custom & Private Label Brands

- Durable Mid-Cut Tactical Boots for Wholesale & Private Label

- Wholesale Waterproof Tactical Boots Custom Suede & High-Traction Soles

- Durable Military Combat Boots with Water Drainage for Wholesale & OEM

- Wholesale Customizable Suede Safety Boots - Puncture-Proof with Velcro Closure

Related Articles

- How Tactical Boots Are Engineered to Last: The Science Behind Long-Lasting Performance

- How Tactical Boots Solve Everyday Challenges: From City Streets to Job Sites

- How Tactical Boots Solve Real-World Challenges: From Work Sites to Wilderness

- How Tactical Boot Engineering Solves Real Outdoor Challenges

- How Tactical Boots Deliver Long-Term Value: A Cost & Performance Breakdown