It’s a frustratingly common scenario for brand owners and distributors. You launch a new line of tactical or work boots based on a classic, rugged-looking design. The marketing highlights its tough, heritage appeal. But then the reports start coming in: customer complaints about comfort, negative reviews about failed seams, and a growing pile of costly returns.

You thought you were selling an icon of durability, but you’re actually dealing with a product that fails under real-world pressure. Why does this happen?

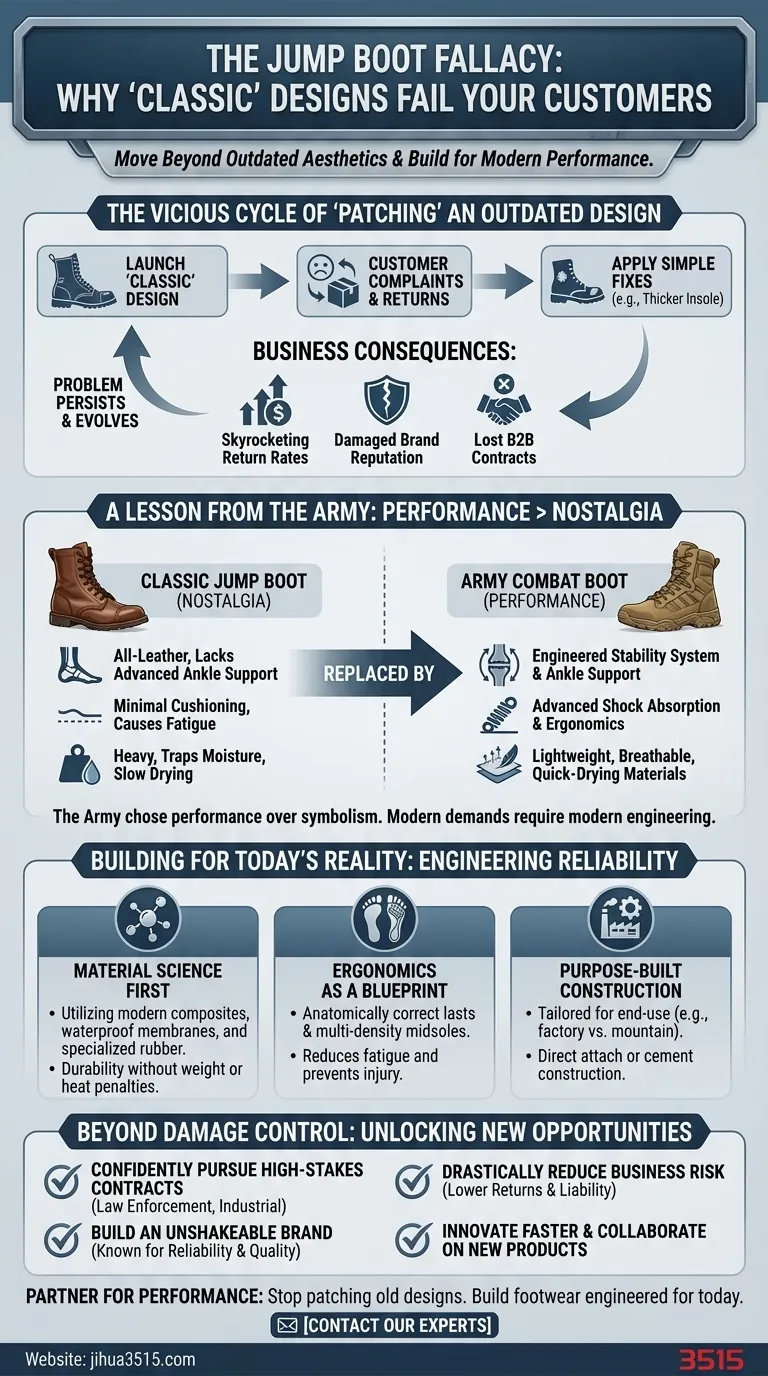

The Vicious Cycle of 'Patching' an Outdated Design

When faced with these issues, the first instinct is to apply simple fixes. "Maybe we need a thicker insole," you might think. Or, "Let's use a heavier grade of leather." So you tweak the spec, relaunch, and hope for the best.

But these are temporary patches on a fundamental problem. The complaints might change, but they don't disappear. This approach doesn't just fail to solve the core issue; it creates significant business consequences:

- Skyrocketing Return Rates: Each return directly eats into your profit margins and creates logistical headaches.

- Damaged Brand Reputation: A few dozen negative online reviews can permanently tarnish your brand's image as a reliable supplier.

- Lost Contracts: For bulk B2B clients like security firms or industrial companies, performance isn't a preference—it's a requirement. A single product failure can cause them to seek a more dependable manufacturing partner.

The real problem isn't a specific component; it’s the entire design philosophy. And for a perfect illustration of this, we only need to look at one of the most iconic boots in history: the U.S. Army jump boot.

A Lesson from the Army: Why Performance Replaced Nostalgia

For decades, the leather jump boot was the unmistakable symbol of the elite paratrooper. It looked tough, it was steeped in history, and it represented the best of 1940s technology. Yet, you will not find soldiers wearing them in a modern combat zone.

Why? Because the military made a critical decision: when lives and mission success are on the line, performance must always win over nostalgia.

The classic jump boot, for all its symbolic power, lacks the features essential for modern demands:

- Advanced Ankle Support: All-leather construction can't provide the engineered stability needed to prevent injuries on rough terrain.

- Modern Cushioning: It offers minimal shock absorption, leading to rapid fatigue.

- Lightweight, Breathable Materials: It's heavy, traps moisture, and dries slowly—all critical liabilities in the field.

The Army didn't try to "fix" the jump boot by adding a new insole. They recognized its design was fundamentally obsolete for modern combat. They replaced it entirely with the Army Combat Boot (ACB), a system engineered from the ground up with advanced material science and ergonomics. The jump boot was honorably retired to ceremonial duties—a symbol of heritage, not a tool for performance.

This is the root of the problem with many "classic-style" boots on the market today. They are based on a design philosophy that has been proven obsolete.

Building for Today’s Reality: The Engineering Behind a Truly Reliable Boot

To escape the cycle of returns and complaints, you don't need a better version of an old design. You need footwear built on the principles of modern performance engineering. A truly reliable boot isn't a matter of looks; it's a product of deliberate design choices.

This is where a manufacturing partner's expertise becomes critical. The solution is to build footwear that is engineered for its intended purpose, using the right combination of materials and construction methods. This includes:

- Material Science First: Utilizing modern composites, waterproof-breathable membranes, and specialized rubber compounds that deliver durability without the weight and heat-retention penalties of traditional all-leather designs.

- Ergonomics as a Blueprint: Designing boots with anatomically correct lasts, multi-density midsoles, and engineered support systems that reduce fatigue and prevent injury.

- Purpose-Built Construction: Understanding that a boot for a factory floor has different requirements than one for a mountain trail, and using the specific construction techniques—like direct attach or cement construction—that best suit the end-use.

A boot built this way isn't just a product; it's a piece of performance equipment. It's conceived, designed, and manufactured based on a deep understanding of why old designs fail in modern contexts.

Beyond Damage Control: Unlocking New Market Opportunities

When you partner with a manufacturer who prioritizes modern engineering over outdated aesthetics, the conversation shifts. You stop worrying about fixing problems and start focusing on growth.

Resolving this fundamental issue of product performance unlocks new potential for your business. You can now:

- Confidently Pursue High-Stakes Contracts: Bid on large-scale orders from law enforcement, emergency services, and industrial clients who have zero tolerance for equipment failure.

- Build an Unshakeable Brand: Become known for reliability and quality, allowing you to command premium prices and foster intense customer loyalty.

- Drastically Reduce Business Risk: Minimize return rates, lower liability exposure, and protect your bottom line.

- Innovate Faster: Collaborate on new product lines that solve emerging customer problems, secure in the knowledge that your manufacturing foundation is solid.

Your customers operate in the present, not the past. Their gear needs to reflect that reality. It's time to stop patching old designs and start building footwear engineered for the demands of today. Our team can help you navigate the complexities of material science and ergonomic construction to create a product line that builds trust and drives growth. To discuss your unique manufacturing challenges, Contact Our Experts.

Visual Guide

Related Products

- Durable Military Combat Boots with Water Drainage for Wholesale & OEM

- Wholesale Tactical Boots High-Traction & Reflective for Bulk & Brand Orders

- Durable High-Ankle Tactical Boots Wholesale Manufacturer for Custom & Bulk Orders

- Durable Leather Tactical Boots Wholesale & Custom Manufacturing for Brands

- Durable Leather High-Ankle Tactical Boots for Wholesale & Custom Manufacturing

Related Articles

- How Tactical Boots Solve Real Workplace Challenges in High-Risk Environments

- How Tactical Boots Are Engineered to Last: The Science Behind Long-Lasting Performance

- How Tactical Boots Solve Everyday Challenges: From City Streets to Job Sites

- How to Verify Tactical Boot Reliability for Life-Saving Performance

- How to Choose Tactical Boots That Match Your Law Enforcement Needs