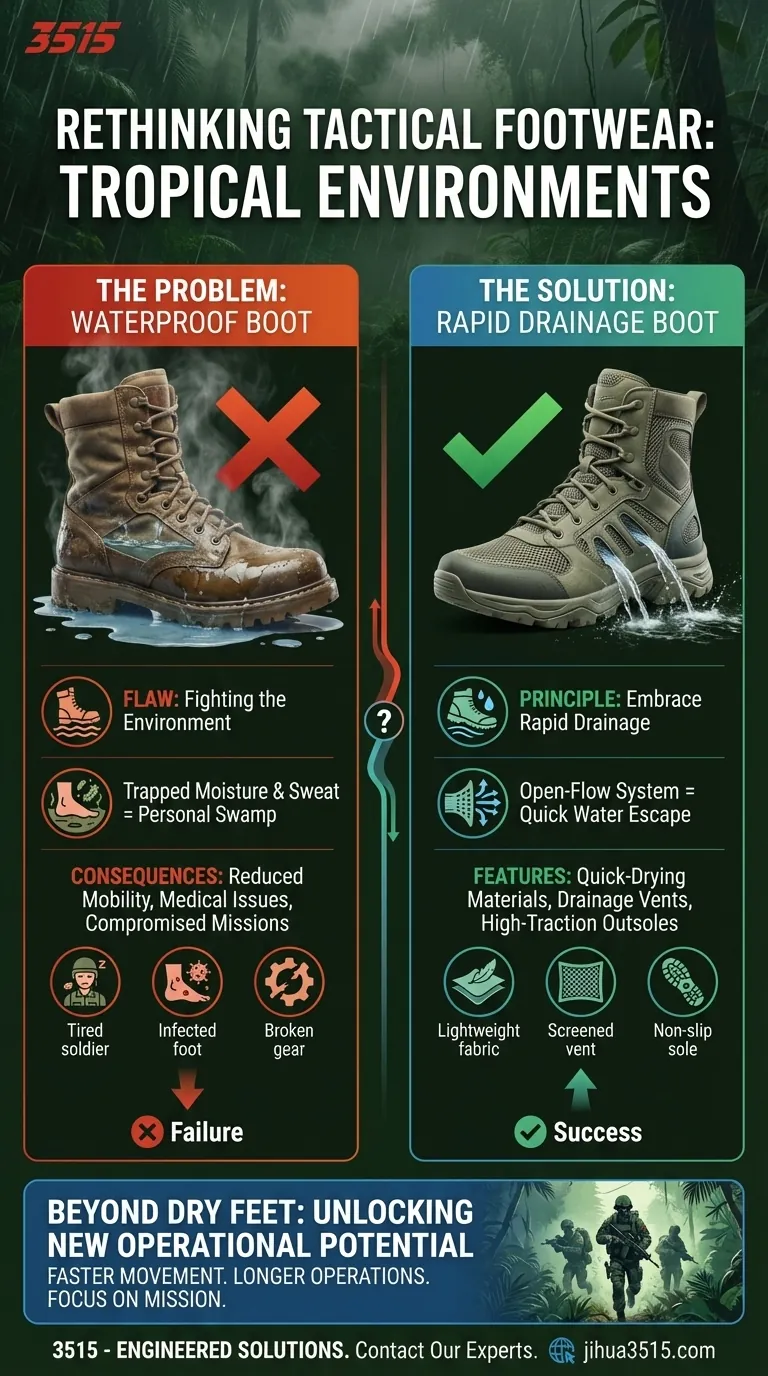

It's a scenario that procurement managers and brand owners dread. You’ve invested heavily in top-of-the-line, waterproof combat boots for your teams operating in a tropical region. They are marketed as the best—durable, protective, and impermeable. Yet, a few weeks into deployment, the field reports are grim. The boots are waterlogged lead weights, blisters are rampant, and foot infections are beginning to compromise operational readiness. The very equipment meant to provide an advantage has become a liability.

The Vicious Cycle of the "Wrong" Solution

This isn't an isolated incident; it's a systemic problem rooted in a common misunderstanding of environmental demands. When faced with wet feet, the intuitive response is to double down on waterproofing. You might look for boots with thicker membranes, sealed seams, or higher cuffs. But in the relentless humidity and constant water exposure of a jungle, this approach almost always fails.

The negative consequences escalate quickly:

- Reduced Mobility: A standard combat boot, once filled with water during a river crossing or downpour, can take days to dry. This added weight fatigues personnel and slows movement.

- Increased Medical Issues: Trapped water and sweat create a perfect breeding ground for bacteria and fungi, leading to debilitating conditions like trench foot that can take a soldier out of action.

- Compromised Missions: A team slowed by foot injuries and heavy gear cannot perform at peak capacity. What starts as a footwear issue quickly becomes a significant operational risk, jeopardizing mission timelines and safety.

For distributors and brands, this translates into a damaged reputation and a product that fails its users when they need it most. The core issue isn't the quality of the boot, but the unsuitability of its core design philosophy for the environment.

The Root Cause: Fighting the Environment Instead of Working With It

The failure of conventional boots lies in a simple, unavoidable truth: in a tropical environment, your feet will get wet. The challenge isn't preventing water from getting in; it's getting it out—and your own sweat—as quickly as possible.

The Flaw in the "Waterproof" Fortress

A waterproof boot is designed like a fortress, intended to keep external moisture out. However, in extreme humidity, it cannot vent the immense amount of perspiration generated by strenuous activity. The "breathable" membrane becomes overwhelmed. The inside of the boot gets damp from sweat alone.

Once the fortress is breached by a stream or deep puddle, its primary strength becomes its greatest weakness. It now holds water in, creating a personal swamp for the wearer's foot. The "solutions" that failed were treating a symptom—wet feet—while ignoring the root cause: the inability to shed water.

The Breakthrough Principle: Embrace Rapid Drainage

The correct approach is counter-intuitive: accept that water will get in and design a system for its rapid escape. This is the core principle behind the modern jungle boot. Instead of a sealed fortress, it's an open-flow system engineered to purge water and promote airflow with every step. It works with the environment, not against it.

The Right Tool, Engineered for the Job

To truly solve the problem, you need footwear built from the ground up on the principle of rapid drainage. This isn't just about adding a few holes; it's an integrated design system where every component serves the goal of drying quickly.

This is where the features of a true jungle boot reveal their purpose:

- Quick-Drying Materials: Lightweight nylon and canvas uppers don't absorb and retain water like heavy leather.

- Drainage Vents: These screened ports, placed on the instep, act as one-way valves, actively pumping water out as the user walks.

- High-Traction Outsoles: Modern designs like Vibram or Dobie patterns provide superior grip on mud, roots, and rocks, which are useless if the user's foot is sliding around inside a waterlogged boot.

At 3515, we understand that superior performance comes from a deep understanding of the operational environment. Our manufacturing process for specialized jungle footwear is centered on creating this integrated drainage system. We don't just assemble boots; we engineer solutions that address the fundamental physics of the challenge, ensuring that the footwear you provide is a genuine asset, not a liability.

Beyond Dry Feet: Unlocking New Operational Potential

When your teams are equipped with the right tool for the job, you do more than just prevent blisters. You unlock a higher level of operational capability.

With footwear designed for the environment, personnel can move faster, operate for longer durations, and maintain focus on the mission instead of their own discomfort and pain. For procurement managers and brand owners, this means providing a product that builds trust and delivers a clear strategic advantage. It means winning contracts, enhancing your reputation for reliability, and, most importantly, ensuring the safety and effectiveness of the end-user.

Solving this persistent footwear problem isn't just an equipment upgrade; it's an investment in mission success. Let our team help you analyze your specific operational needs and engineer a footwear solution that gives your personnel the edge they deserve. Contact Our Experts.

Visual Guide

Related Products

- Safety Footwear Wholesale Manufacturer for Custom OEM/ODM Production

- High-Traction Suede Tactical Boots Wholesale & Custom Manufacturing

- High Performance Fire-Retardant Waterproof Safety Boots

- Customizable Anti-Smash Safety Boots for Wholesale & Private Label Manufacturing

- Custom Wholesale Leather Safety Boots Direct Factory Manufacturing

Related Articles

- How Steel Toe Shoes Meet Safety Standards and Prevent Workplace Injuries

- How to Choose Steel Toe Shoes That Balance Safety and Comfort

- How Steel Toe Boots Deliver Financial and Safety Returns in High-Risk Workplaces

- How Steel Toe Boots Meet Industry Safety Standards and Reduce Workplace Injuries

- How to Choose Between Steel and Composite Toe Boots for Maximum Safety