When workplace hazards loom, the right work boots aren't just about comfort—they're your first line of defense. This guide deciphers safety standards, material science, and hazard-specific solutions to help you select boots that meet OSHA and ASTM requirements while addressing real-world risks.

Work Boot Safety Decoded

Material Science Behind Protection

Steel toe boots have long been the industry standard, but composite alternatives (made from carbon fiber, Kevlar, or plastic) now compete fiercely. Here’s how they compare:

- Impact Resistance: Both steel and composite toes must withstand 75 foot-pounds of force while maintaining a half-inch clearance (for men) under ASTM F2413.

- Weight: Composite materials reduce boot weight by roughly 30%, easing fatigue during long shifts.

- Temperature Sensitivity: Steel conducts heat/cold, making it unsuitable for extreme environments. Composites insulate better.

Key Question: Have you considered how boot weight impacts productivity in high-mobility jobs?

When Metal Detectors and Weight Matter

Composite toes excel in:

- Airports or secure facilities where metal detectors are used

- Electrical hazard (EH) environments (non-conductive materials prevent current flow)

- Cold storage warehouses (no thermal transfer)

Steel toes remain preferable for:

- Heavy industrial sites with crushing hazards (e.g., construction)

- Budget-conscious buyers (often 20–40% cheaper upfront)

Beyond Basic Protection: ASTM Ratings Explained

ASTM F2413 labels indicate critical protections:

- EH: Electrical hazard resistance (up to 600V in dry conditions)

- PR: Puncture-resistant midsoles

- MT: Metatarsal guards for foot-top impact protection

Pro Tip: Look for the CSA White rectangle with an orange Ω symbol for ultra-high-voltage protection (up to 18,000V).

Industry-Sized Solutions

Construction Sites vs. Airport Security: A Boot Matchmaking

| Hazard Type | Recommended Boot | Why It Works |

|---|---|---|

| Falling objects | Steel toe with MT rating | Maximum crush protection |

| Metal detectors | Composite toe | No alarm triggers |

| Slippery surfaces | Both + oil-resistant soles | ASTM F2913 traction |

Cold Storage Warehouses and Electrical Hazards: What You’re Overlooking

Composite boots dominate here:

- Thermal Insulation: Prevents frostbite in subzero temperatures.

- EH Compliance: Non-metallic materials avoid conductivity risks near live wires.

Key Question: Could your current boots be silently compromising safety in temperature extremes?

Longevity and Compliance

How to Validate Boot Safety Claims

- Check Labels: Verify ASTM/OSHA compliance stamps inside the tongue or shaft.

- Ask for Test Data: Reputable manufacturers provide third-party certification reports.

- Employer Policies: Some sites mandate specific ratings (e.g., EH for utility workers).

Maintenance Myths Debunked

-

Myth: "Composite toes degrade faster."

Truth: Proper care (cleaning with mild soap, avoiding direct heat) extends lifespan comparably to steel. -

Myth: "All EH-rated boots are equal."

Truth: Voltage thresholds vary—match ratings to your workplace’s risks.

Step Into Safety with 3515

Whether you’re a distributor stocking up or a brand owner seeking OEM solutions, 3515 delivers rigorously tested work boots tailored to your hazard profile. From steel toes for construction crews to lightweight composites for airport staff, our production scale ensures compliance without compromise.

Ready to equip your workforce with boots that meet and exceed safety standards? Contact 3515 today to discuss bulk solutions engineered for real-world protection.

Related Products

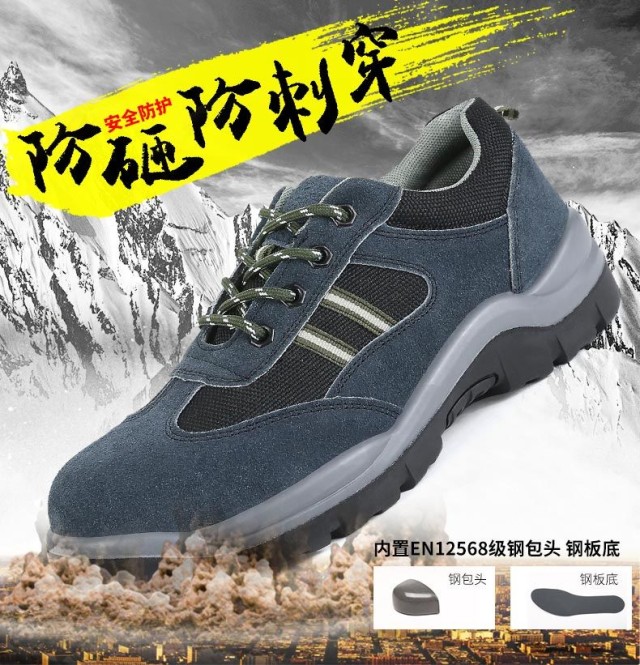

- Wholesale Customizable Suede Safety Boots - Puncture-Proof with Velcro Closure

- Puncture-Resistant Velcro Safety Boots for Wholesale & Custom Manufacturing

- Customizable Anti-Smash Safety Boots for Wholesale & Private Label Manufacturing

- Wholesale Leather Safety Boots with Customizable Protective Toe

- Durable Leather Safety Boots for Wholesale & Custom OEM Manufacturing

Related Articles

- How to Choose Work Boot Materials for Maximum Safety and Durability

- How to Choose Work Boots That Match Your Job Demands and Safety Needs

- How Safety Work Boots Engineer Protection: Features and Standards for Targeted Hazard Mitigation

- How to Choose Work Boots That Balance Safety, Comfort, and Durability for Your Job

- Steel Toe Work Boots: Balancing Safety and Comfort for Demanding Jobs