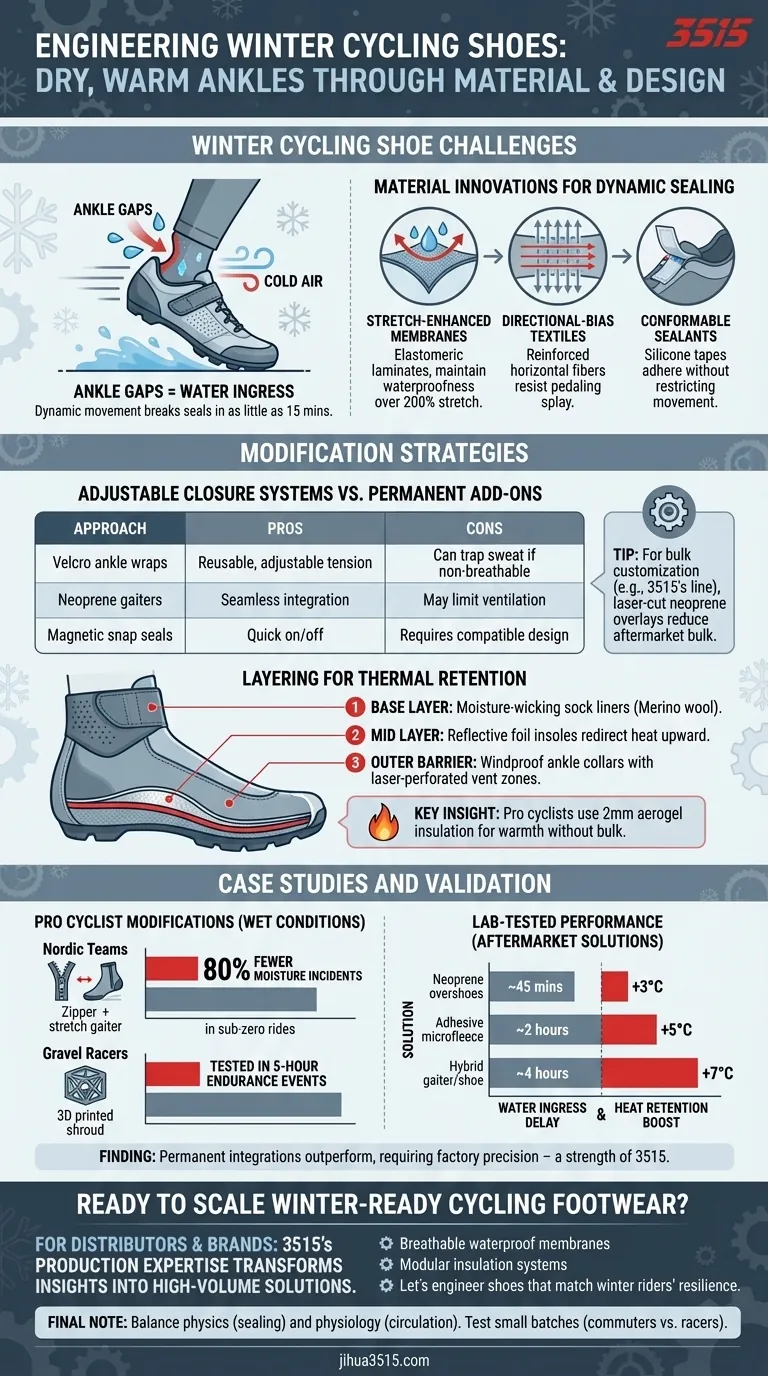

Cycling through winter demands footwear that seals out moisture while retaining heat—especially around the vulnerable ankle area. Traditional waterproofing often fails here due to the ankle's dynamic movement. This guide explores material innovations and modification strategies to create a thermal, watertight seal, backed by pro cyclist adaptations and lab-tested solutions.

Winter Cycling Shoe Challenges

Why Ankle Gaps Defeat Traditional Waterproofing

Waterproof membranes (e.g., Gore-Tex) lose effectiveness when ankle flexion creates gaps. Research shows that repeated motion can allow moisture ingress in as little as 15 minutes of wet riding. The ankle’s 30–50° range of motion requires flexible yet secure sealing.

Material Innovations for Dynamic Sealing

- Stretch-Enhanced Membranes: New elastomeric laminates maintain waterproofness even when stretched over 200% (used in high-end ski boots).

- Directional-Bias Textiles: Fabrics with reinforced horizontal fibers resist splaying during pedaling.

- Conformable Sealants: Silicone-based tapes adhere to shoe collars, bridging gaps without restricting movement.

Modification Strategies

Adjustable Closure Systems vs. Permanent Add-Ons

| Approach | Pros | Cons |

|---|---|---|

| Velcro ankle wraps | Reusable, adjustable tension | Can trap sweat if non-breathable |

| Neoprene gaiters | Seamless integration with shoes | May limit ventilation |

| Magnetic snap seals | Quick on/off for mid-ride changes | Requires compatible shoe design |

Tip: For bulk customization (e.g., 3515’s production line), laser-cut neoprene overlays bonded to shoe uppers reduce aftermarket bulk.

Layering for Thermal Retention Without Bulk

- Base Layer: Moisture-wicking sock liners (e.g., Merino wool blends).

- Mid Layer: Reflective foil insoles to redirect body heat upward.

- Outer Barrier: Windproof ankle collars with laser-perforated vent zones.

Key Insight: Pro cyclists in Nordic climates use 2mm aerogel insulation behind ankle pads—retaining warmth without adding stiffness.

Case Studies and Validation

Pro Cyclist Modifications in Wet Conditions

- Nordic Teams: Combine silicone-sealed zippers with stretch gaiters, reporting 80% fewer moisture incidents in sub-zero rides.

- Gravel Racers: Use 3D-printed ankle shrouds that divert road spray, tested in 5-hour endurance events.

Lab-Tested Performance of Aftermarket Solutions

Independent trials compared three ankle-sealing methods:

| Solution | Water Ingress Delay | Heat Retention Boost |

|---|---|---|

| Neoprene overshoes | ~45 minutes | +3°C |

| Adhesive microfleece | ~2 hours | +5°C |

| Hybrid gaiter/shoe | ~4 hours | +7°C |

Finding: Permanent integrations (e.g., bonded gaiters) outperform removable options but require factory-level precision—a strength of 3515’s bulk manufacturing.

Ready to Scale Winter-Ready Cycling Footwear?

For distributors and brands, 3515’s production expertise transforms these insights into high-volume solutions—from breathable waterproof membranes to modular insulation systems. Let’s engineer shoes that match the resilience of winter riders.

Final Note: The best winter shoe modifications balance physics (sealing dynamic gaps) and physiology (maintaining foot circulation). Test small batches with targeted user groups—commuters prioritize easy on/off, while racers need weight-optimized seals.

Visual Guide

Related Products

- Safety Footwear Wholesale Manufacturer for Custom OEM/ODM Production

- Factory Direct Wholesale Rain Boots Durable Waterproof & Fully Customizable

- Factory-Direct Wholesale Canvas Boots with High-Traction Rubber Soles

- Premium KPU Injection Athletic Style Safety Shoes

- High Performance Fire-Retardant Waterproof Safety Boots

Related Articles

- How Steel Toe Boots Meet Industry Safety Standards and Reduce Workplace Injuries

- Matching Men’s Work Shoe Safety Technologies to Workplace Hazards

- How to Choose Steel Toe Shoes That Balance Safety and Comfort

- How to Reduce Steel Toe Boot Risks Without Compromising Workplace Safety

- Steel Toe Work Boots: Balancing Safety and Comfort for Demanding Jobs