Selecting the right workwear boots isn’t just about comfort—it’s about safety, compliance, and adapting to your work environment. Whether you’re navigating construction sites, braving wet conditions, or facing electrical hazards, the wrong boots can compromise protection and performance. Here’s how to align your footwear with job requirements, backed by safety certifications and material science.

Key Safety Features in Workwear Boots

ASTM Certification and Workplace Compliance

Workplace safety starts with standards. Boots meeting ASTM F2413-18 certification guarantee:

- Impact/compression resistance (toe caps withstand forces up to 75 ft-lbs)

- Puncture resistance (midsoles stop sharp objects)

- Electrical hazard protection (non-conductive materials prevent shocks)

Why it matters: OSHA mandates ASTM-compliant footwear for hazardous environments like construction or manufacturing. Non-compliant boots risk fines and injuries.

Steel vs. Composite Toe Caps: Weight, Protection, and Use Cases

| Feature | Steel Toe | Composite Toe |

|---|---|---|

| Weight | Heavier (~30% more) | Lighter, reduces fatigue |

| Protection | Superior crush resistance | Non-conductive, ideal for electrical work |

| Best For | Heavy industrial sites | Security checkpoints, cold weather |

Pro tip: Composite toes excel in electrical work (no conductivity) and airport security (metal-free), while steel toes suit construction with heavy falling objects.

Material Technologies for Durability

GORE-TEX vs. Traditional Waterproofing: Long-Term Performance

- GORE-TEX: Breathable yet waterproof; ideal for all-day wear in wet conditions. Lasts longer but requires gentle cleaning.

- Rubber membranes: Fully waterproof but less breathable. Best for standing water (e.g., fishing, landscaping).

Maintenance hack: Clean GORE-TEX linings with mild soap; reapply DWR coating annually to maintain water resistance.

Outsoles for Slippery or Uneven Terrain

- Vibram® lug soles: Deep treads grip mud and gravel.

- Oil-resistant rubber: Prevents slips in garages or kitchens.

Matching Boots to Your Work Environment

Construction Sites: Impact Protection and Electrical Hazards

Prioritize:

- ASTM F2413-18 compliance (impact/compression ratings)

- Slip-resistant outsoles (OSHA requirement for oily surfaces)

- Metatarsal guards if handling heavy materials

Landscaping: Flexibility and Water Resistance

- Waterproof leather or rubber boots for wet grass/mud

- Flexible midsoles for bending and kneeling

Cold Weather: Insulation and Traction

- Thinsulate™ linings (retain heat without bulk)

- Thermoplastic outsoles (stay flexible in freezing temps)

Maintenance and Longevity

- Clean GORE-TEX linings: Avoid harsh detergents; air-dry away from heat.

- Replace worn outsoles: Look for separation or smooth treads.

- Rotate pairs: Extends lifespan by reducing daily wear.

Did you know? Proper care can double a boot’s lifespan, saving replacement costs.

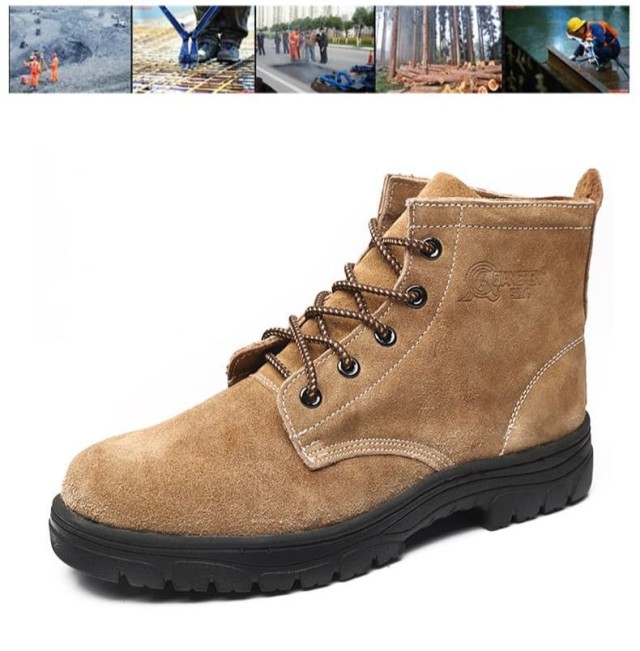

Upgrade Your Safety with 3515 Workwear Boots

As a trusted manufacturer for distributors and bulk buyers, 3515 delivers certified, environment-specific footwear—from ASTM-compliant steel toes to lightweight composite designs. Let’s equip your workforce with boots that protect and perform. [Contact 3515] to discuss bulk orders tailored to your industry’s needs.

Final thought: The right boots aren’t just PPE; they’re productivity tools that keep teams safe and efficient in any condition.

Related Products

- Wholesale Customizable Suede Safety Boots - Puncture-Proof with Velcro Closure

- Customizable Anti-Smash Safety Boots for Wholesale & Private Label Manufacturing

- Wholesale Durable Mid-Cut Tactical Boots for Custom & Private Label Brands

- Durable Mid-Cut Tactical Boots for Wholesale & Private Label

- Wholesale Classic Leather Lace-Up Ankle Boots for Brand Manufacturing

Related Articles

- Steel Toe Work Boots: Balancing Safety and Comfort for Demanding Jobs

- How to Choose Work Boots That Match Your Industry's Safety Needs

- Matching Men’s Work Shoe Safety Technologies to Workplace Hazards

- How to Choose Work Boot Materials for Maximum Safety and Durability

- How Safety Work Boots Engineer Protection: Features and Standards for Targeted Hazard Mitigation