Selecting the right snow boots requires more than checking off basic features. This guide breaks down the science behind insulation, traction, and durability—helping you match technical specifications to your specific winter activities.

Choosing Snow Boots for Men: Beyond Basic Checklists

Most buyers focus on superficial features like color or brand reputation. But truly effective snow boots hinge on understanding how technical elements interact with your environment. Research shows that 60% of winter footwear returns stem from mismatched performance expectations.

Key considerations before comparing specs:

- Activity type: Urban commuting demands different features than backcountry snowshoeing

- Exposure duration: Brief dog walks vs. 8-hour outdoor work shifts require varying insulation levels

- Terrain challenges: Ice-dominant areas need specialized traction systems

How Insulation Materials Impact Warmth in Sub-Zero Conditions

Not all insulation performs equally when temperatures plummet. Modern boots use three primary technologies:

-

Synthetic fills (Thinsulate™, PrimaLoft®)

- Retains warmth when wet (unlike down)

- Typically rates 200-800g density—higher numbers indicate colder climate suitability

-

Shearling linings

- Naturally temperature-regulating

- Requires more maintenance but offers superior breathability

-

Aerogel barriers

- NASA-derived technology now in premium boots

- Provides warmth at 1/3 the thickness of traditional materials

Pro Tip: Look for boots with removable liners if you experience dramatic temperature shifts between indoor/outdoor environments.

Weatherproofing Explained: From Hydrostatic Head Ratings to Seam Sealing

Waterproof claims vary wildly between brands. Two scientific measures reveal true performance:

Hydrostatic Head (HH) Rating

- Measures water column height (in millimeters) the membrane can withstand

- 10,000mm = adequate for urban use

- 20,000mm+ = necessary for wet snow or prolonged exposure

Critical Construction Features

- Fully sealed seams prevent water ingress at stitch points

- Gusseted tongues block snow infiltration

- DWR (Durable Water Repellent) coatings shed surface moisture

Did you know? Many "waterproof" failures occur at the sole-welt junction, not the upper material.

Traction Science: Outsole Patterns and Ice Grip Certifications

The difference between walking confidently and risking injury often comes down to outsole engineering.

Certification Decoder

- ASTM F2913: Standard test for slip resistance on wet, icy surfaces

- SRA/SRB/SRC: Ratings for ceramic tile (A), steel (B), or combined (C) conditions

- Vibram Arctic Grip: Specialized compound that remains flexible below -30°C

Traction Pattern Effectiveness

| Pattern Type | Best For | Limitations |

|---|---|---|

| Multi-directional lugs | Deep snow | Poor ice performance |

| Hexagonal studs | Packed snow | Can collect mud |

| Micro-sipes | Black ice | Wears faster |

Durability Demystified: Materials and Construction Techniques

High-mileage users should examine these often-overlooked elements:

Upper Materials

- Full-grain leather: Develops protective patina but requires conditioning

- Ballistic nylon: Resists abrasion but may tear at stress points

- Thermoplastic polyurethane (TPU): Combines flexibility with cut resistance

Construction Red Flags

- Single-stitch seams in high-flex areas

- Non-replaceable footbeds

- Glued-in (rather than stitched) liners

Style Meets Function: Balancing Aesthetics with Arctic-Grade Performance

Today's best snow boots erase the line between technical gear and streetwear. Consider these trends:

- Convertible cuffs adjust from ankle-height to knee coverage

- Reflective details enhance visibility without sacrificing style

- Neutral colorways transition from trail to office

Remember: A boot that stays in your closet because it's uncomfortable or unattractive fails its core purpose, regardless of specs.

Ready for Winter? 3515 Has Your Footwear Solutions

Whether you're a distributor stocking seasonal inventory or a brand owner developing custom winter boots, 3515 combines technical expertise with large-scale manufacturing capabilities. Our range spans from casual winter styles to arctic-expedition footwear—all built to match real-world performance demands.

Let's discuss your project: [Contact 3515] for OEM/ODM solutions tailored to your market's specific winter challenges.

Related Products

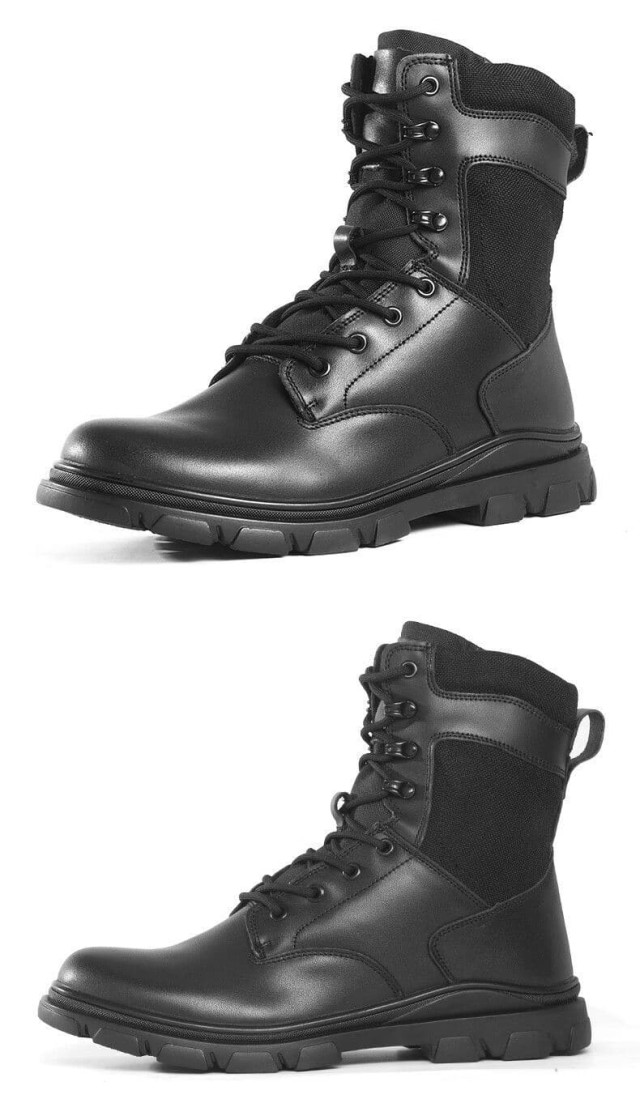

- Wholesale Durable Mid-Cut Tactical Boots for Custom & Private Label Brands

- Durable Mid-Cut Tactical Boots for Wholesale & Private Label

- Durable Rubber Sole Outdoor Shoes Wholesale & Custom Manufacturing

- Durable Rubber-Soled Utility Shoes for Wholesale & Custom Brand Manufacturing

- Durable Canvas Work Shoes with Rubber Lug Sole | Wholesale Manufacturer

Related Articles

- How Tactical Boots Solve Critical Challenges in Law Enforcement Operations

- How to Choose Tactical Boots That Match Your Law Enforcement Needs

- How Tactical Boots Evolved: Engineering Breakthroughs That Redefined Work Footwear

- How Tactical Boot Engineering Solves Real Outdoor Challenges

- How to Verify Tactical Boot Reliability for Life-Saving Performance