For soldiers, law enforcement, and outdoor professionals, the right boots aren't just equipment—they're critical tools that prevent injuries and withstand extreme conditions. This guide reveals how to select and maintain tactical footwear that protects your body and endures years of hard use.

Selecting Tactical Footwear for High-Stress Environments

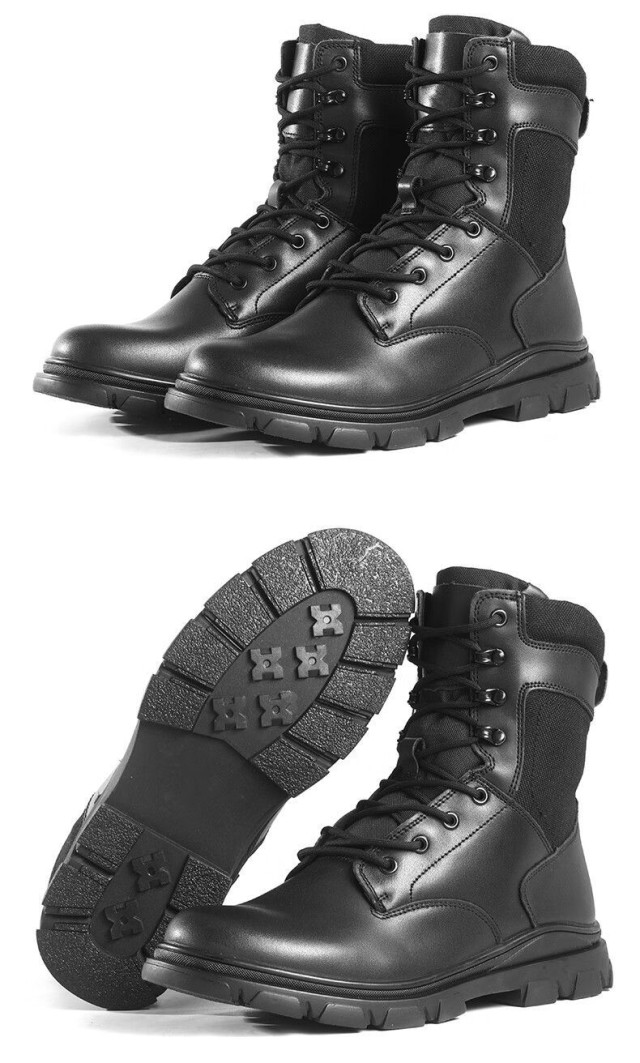

Military boots must balance support, flexibility, and durability. Poorly designed footwear can lead to chronic pain, stress fractures, or premature failure when you need reliability most.

The Science Behind Boot Fit and Injury Risk

Research shows that improper fit contributes to over 60% of foot-related injuries in field operations. Key considerations include:

- Width options: Standard, wide, and extra-wide variants accommodate natural foot swelling during prolonged activity.

- Safety toe space: A thumb’s width between toes and the boot end prevents nail damage during downhill movement.

- Heel stability: Lockdown mechanisms (like contoured heel cups) reduce blister-causing friction.

- Break-in periods: High-quality materials (e.g., full-grain leather) require gradual flexing to mold to your foot shape.

Pro Tip: Always test boots with the socks you’ll wear in the field. Thickness dramatically alters fit.

Field-Testing Protocols Beyond Basic Walking

Simulate real-world conditions to assess performance:

- Load testing: Walk 5+ miles with a weighted pack to check for pressure points.

- Incline/decline trials: Verify toe clearance and ankle support on 30° slopes.

- Wet conditioning: Submerge boots for 30 minutes, then check for seam leaks or sole separation.

Early Warning Signs: Hot spots after 20 minutes of wear often indicate long-term fit issues.

Optimizing Boot Longevity From Day One

Durability hinges on two factors: construction quality and maintenance habits. Even premium boots fail prematurely without proper care.

Surface Testing Nuances for Home Trials

Replicate abrasive environments to evaluate materials:

- Gravel drag test: Scrape soles against rough pavement to check tread bonding.

- Flex cycles: Bend the forefoot 50+ times; excessive creasing suggests weak material.

- Chemical exposure: Apply saline solution (mimicking sweat) to test corrosion-resistant hardware.

Did You Know? Boots used in chemical processing zones degrade 3x faster without specialized coatings.

Interpreting Early Warning Signs of Poor Fit

Watch for these red flags in the first 30 days:

- External wear: Uneven heel erosion signals gait misalignment.

- Internal breakdown: Liner pilling or insole compression reduces shock absorption.

- Odor buildup: Persistent smells indicate moisture-wicking failures.

Maintenance Routine:

- Clean with cold water (hot water damages leather fibers).

- Air-dry away from heat sources to prevent glue deterioration.

- Condition leather monthly to maintain water resistance.

Trust 3515 for Tactical Footwear That Performs When It Matters

For distributors and bulk buyers, 3515 combines defense-grade engineering with scalable production. Our boots undergo 200+ quality checks, from flexion endurance to chemical resistance testing—ensuring your clients get footwear that protects their feet and their investment.

Ready to equip professionals with reliable footwear? Partner with 3515 to access durable, injury-preventing boots designed for real-world demands.

Related Products

- Wholesale Waterproof Tactical Boots Custom Suede & High-Traction Soles

- Durable Mid-Cut Tactical Boots for Wholesale & Private Label

- Wholesale Durable Mid-Cut Tactical Boots for Custom & Private Label Brands

- Wholesale Customizable Suede Safety Boots - Puncture-Proof with Velcro Closure

- Durable Military Combat Boots with Water Drainage for Wholesale & OEM

Related Articles

- How Tactical Boots Solve Real-World Challenges: From Work Sites to Wilderness

- How Tactical Boots Are Engineered to Last: The Science Behind Long-Lasting Performance

- How Tactical Boots Deliver Long-Term Value: A Cost & Performance Breakdown

- How Tactical Boots Evolved: Engineering Breakthroughs That Redefined Work Footwear

- How Tactical Boot Engineering Solves Real Outdoor Challenges