For over 150 years, Goodyear welt construction has set the benchmark for durable, repairable footwear. This article explores why this method remains the gold standard for premium shoes—delivering unmatched longevity, weather resistance, and comfort that cheaper alternatives can’t replicate.

The Invention That Revolutionized Footwear

From Hand-Stitching to Global Standardization

Before 1869, shoemaking relied on labor-intensive hand-stitching. The Goodyear welt machine, patented by Charles Goodyear Jr. (son of the vulcanized rubber inventor), automated the process of attaching soles to uppers via a leather strip (welt). This innovation:

- Reduced production time by ~70% compared to hand-welting

- Standardized quality across mass-produced footwear

- Enabled the welt’s signature water-resistant barrier

Engineering Breakthroughs

The machine’s precision stitching created a triple-layer defense:

- Upper Leather: Forms the shoe’s exterior

- Welt: A 1.5cm leather strip sewn to the upper

- Outsole: Stitched to the welt, not the upper

This separation allows soles to be replaced without damaging the upper—a first in footwear history.

Fun fact: Early Goodyear welt machines weighed over 2 tons, yet produced stitches accurate to 0.5mm tolerances.

Why Goodyear Welt Outlasts Other Methods

The Triple-Layer Durability Mechanism

Research shows Goodyear-welted shoes withstand 3–5× more wear cycles than cemented soles before requiring repairs. The secret lies in:

- Distributed Stress: Stitches absorb impact instead of glue bonds

- Cork Filling: Molds to the foot while resisting compression

- Metal Shank: Prevents midsole collapse

Moisture Resistance and Comfort Design

Unlike Blake-stitched shoes (where seams pierce the insole), Goodyear welts:

- Create a watertight seal via external stitching

- Use cork that expands slightly when wet, improving the seal

- Allow uppers to dry faster after exposure

Pro tip: The cork layer takes ~2 weeks of wear to fully adapt to your foot’s shape.

The Modern Legacy of a 19th-Century Innovation

Luxury Brands Upholding the Tradition

Leading manufacturers like Allen Edmonds and Red Wing use Goodyear welts because:

- Patina Development: High-quality leather uppers age gracefully over decades

- Resole Capacity: Average of 5–7 resoles per pair

- Arch Support: The construction naturally stabilizes foot motion

Sustainability Through Resoling

With 300M+ shoes discarded annually, Goodyear welts cut waste by:

- Extending shoe life to 15–20 years (vs. 2–3 years for fast fashion)

- Using biodegradable materials: leather, cork, and cotton thread

- Local cobblers can replace soles for ~20% of original shoe cost

Decoding Myths and Realities

Goodyear Welt vs. Blake Stitch: Key Differences

| Feature | Goodyear Welt | Blake Stitch |

|---|---|---|

| Water Resistance | Excellent (external stitching) | Moderate (stitches penetrate insole) |

| Repairability | Easy resoling | Limited to ~2 resoles |

| Flexibility | Stiffer, better for boots | More flexible, suited for dress shoes |

When the Construction Isn’t Worth the Cost

Goodyear welts may be overkill if you:

- Need ultra-lightweight shoes (e.g., for travel)

- Prefer disposable fashion trends over long-term wear

- Have foot conditions requiring custom orthotics

Ready to experience footwear that improves with age? 3515 equips distributors and brands with premium Goodyear-welted shoes designed for decades of service. [Contact us] to explore bulk pricing for your next collection.

Final thought: In an era of disposable fashion, Goodyear welts represent the rare product that rewards patience—transforming from mere shoes into personalized artifacts of craftsmanship.

Related Products

- Safety Footwear Wholesale Manufacturer for Custom OEM/ODM Production

- Wholesale Anti-Smash & Puncture-Proof Safety Shoes Custom Manufacturing for Brands

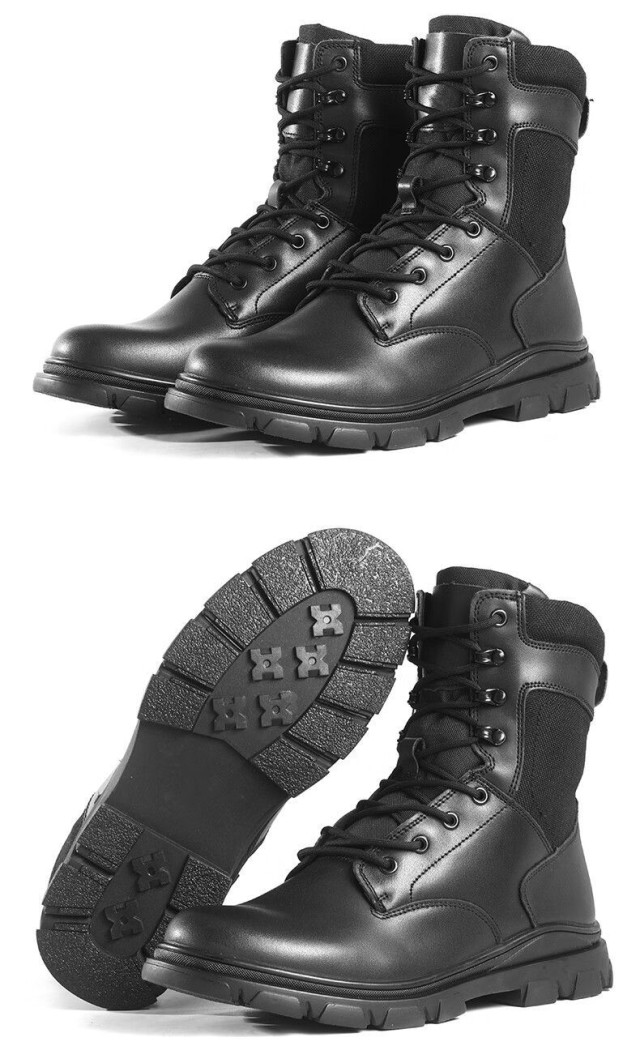

- Wholesale Durable Mid-Cut Tactical Boots for Custom & Private Label Brands

- Wholesale Safety Footwear Manufacturer for Bulk & Custom OEM Orders

- Athletic Safety Shoes with Dial Closure & Steel Toe for Wholesale & Custom Manufacturing

Related Articles

- How to Prevent Foot Injuries from Steel Toe Boots Without Sacrificing Safety

- How to Choose Safety Footwear That Solves Steel Toe Shoe Problems Without Sacrificing Protection

- How to Choose Steel Toe Shoes That Balance Safety and Comfort

- How Steel Toe Shoes Prevent Injuries: The Science Behind Workplace Safety

- Matching Men’s Work Shoe Safety Technologies to Workplace Hazards