From the moment they are first worn, the protective qualities of slip-resistant shoes begin to degrade. An industrial footwear program must include provisions for regular replacement because the very features that provide safety—sole material and tread pattern—wear down with use. This wear is not a sign of a defective product but an inevitable physical process that, if ignored, directly increases the risk of preventable workplace accidents.

Treating slip-resistant shoes as a durable, long-term asset is a critical safety miscalculation. Their protective qualities are a consumable resource that depletes with every step, making a scheduled replacement program the only effective way to ensure consistent protection against slips, trips, and falls.

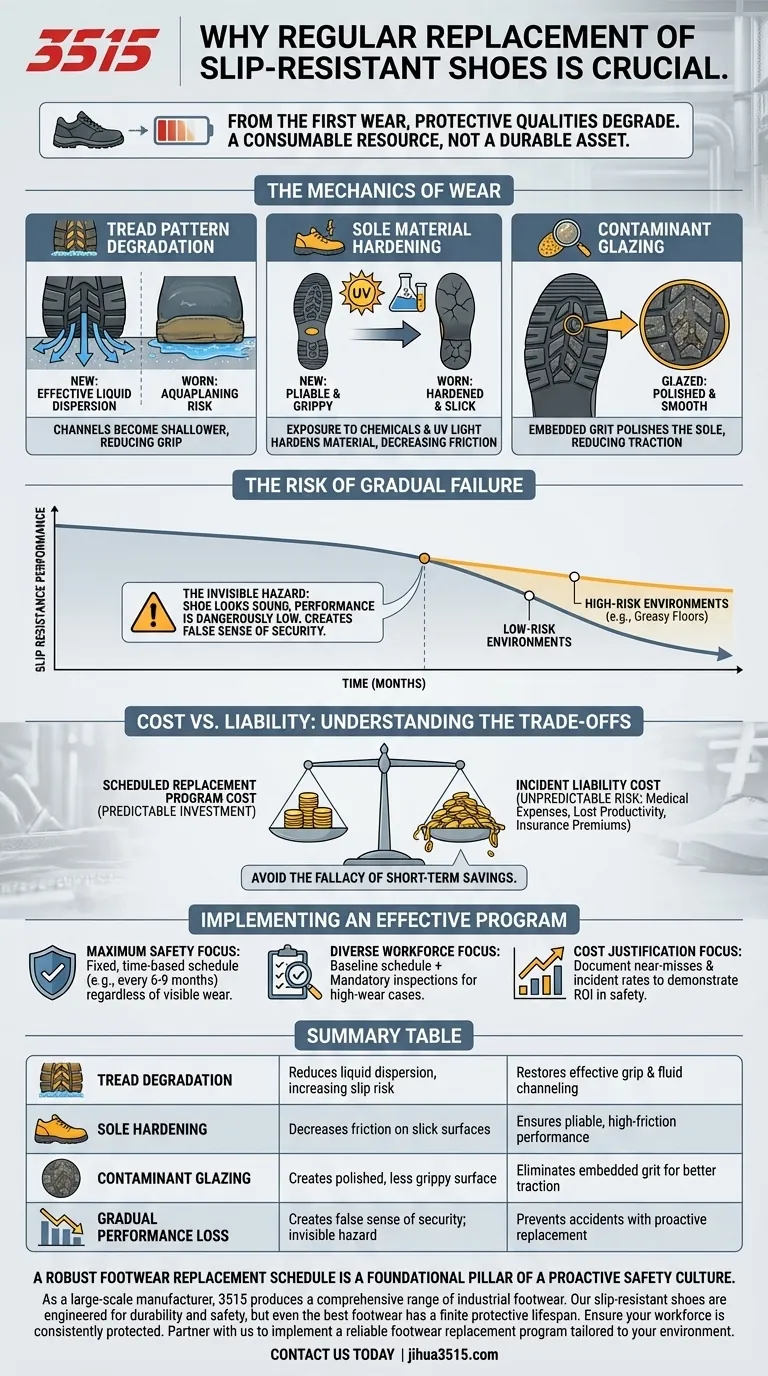

The Mechanics of Wear: How Safety Degrades Over Time

The effectiveness of a slip-resistant shoe is not a permanent feature. It is an engineered system with a finite operational lifespan, influenced directly by physical wear and environmental exposure.

Tread Pattern Degradation

The deep channels and intricate patterns on a shoe's outsole are designed to do one thing: channel liquids out from under the foot. This allows the sole to make direct contact with the floor surface, maximizing grip.

As an employee walks, the sole abrades against the floor, slowly wearing down the tread. The channels become shallower, reducing their capacity to disperse fluids like water, grease, or oil. This can create a situation similar to a car's tires aquaplaning on a wet road, where a thin layer of liquid prevents effective contact and leads to a sudden loss of traction.

Sole Material Hardening

The specialized rubber and polymer compounds used in outsoles are formulated for a high coefficient of friction. However, these materials degrade over time.

Constant exposure to cleaning chemicals, industrial oils, and even UV light can cause the material to harden and lose its pliable, "grippy" nature. A hardened sole has significantly less friction and is more likely to slide across a slick surface.

Contaminant Glazing

Work environments are rarely pristine. Microscopic grit and dirt can become embedded in the soft material of the outsole over thousands of steps.

This process, known as glazing, effectively polishes the bottom of the shoe. It creates a smoother, less effective gripping surface at a microscopic level, even if the primary tread pattern still appears intact.

The Risk of Gradual Failure

The most significant danger of footwear degradation is its slow, almost imperceptible nature. Unlike a sudden equipment failure, the loss of slip resistance happens gradually over months, creating a false sense of security for the wearer.

The Invisible Hazard

A shoe can look structurally sound while offering dangerously low levels of slip resistance. Employees become accustomed to the feel of their footwear and are unlikely to notice the incremental decline in performance until it is too late.

Environment as an Accelerator

The rate of degradation is not uniform across all job functions. An employee in a greasy food service environment or on a factory floor with cutting fluids will experience much faster sole degradation than someone in a hospital corridor where spills are primarily water-based.

A robust program must account for these environmental differences. Assuming a single "wear-out" timeline for all employees can leave those in the highest-risk roles dangerously exposed.

Understanding the Trade-offs: Cost vs. Liability

Implementing a scheduled replacement program has a clear line-item cost. However, failing to do so carries far greater, albeit less predictable, financial and human risks.

The Fallacy of Short-Term Savings

Viewing footwear as a one-time purchase to be used until it falls apart is a flawed economic model. The cost of a single serious slip-and-fall incident—including medical expenses, lost productivity, and increased insurance premiums—can easily eclipse the cost of outfitting an entire department with new, effective footwear for a year.

The Challenge of a Universal Policy

A one-size-fits-all replacement schedule can be inefficient. An employee who is mostly stationary may not need new shoes as frequently as a colleague who walks several miles per shift on abrasive concrete.

Effective programs often establish a baseline replacement period (e.g., every 12 months) and supplement it with regular supervisory inspections to identify and replace high-wear footwear sooner.

Implementing an Effective Replacement Program

To translate this understanding into action, your program must be clear, consistent, and tailored to your specific operational environment.

- If your primary focus is maximum safety in high-risk environments (e.g., greasy kitchens, factory floors): Implement a fixed, time-based replacement schedule (e.g., every 6-9 months) regardless of visible wear.

- If your primary focus is managing a large, diverse workforce with varied roles: Combine a baseline replacement schedule with a mandatory employee inspection process to identify high-wear cases for earlier replacement.

- If your primary focus is justifying program costs to leadership: Document near-misses and track incident rates before and after implementing the program to demonstrate a clear return on investment in safety.

A robust footwear replacement schedule is not a cost center; it is a foundational pillar of a proactive and resilient safety culture.

Summary Table:

| Aspect of Wear | Impact on Safety | Replacement Justification |

|---|---|---|

| Tread Pattern Degradation | Reduces liquid dispersion, increasing slip risk | Restores effective grip and fluid channeling |

| Sole Material Hardening | Decreases friction on slick surfaces | Ensures pliable, high-friction outsole performance |

| Contaminant Glazing | Creates a polished, less grippy surface | Eliminates embedded grit for better traction |

| Gradual Performance Loss | Creates false sense of security; invisible hazard | Prevents accidents with proactive replacement schedules |

As a large-scale manufacturer, 3515 produces a comprehensive range of industrial footwear for distributors, brand owners, and bulk clients. Our slip-resistant shoes are engineered for durability and safety, but even the best footwear has a finite protective lifespan.

Ensure your workforce is consistently protected against slips, trips, and falls. Partner with us to implement a reliable footwear replacement program tailored to your environment—whether it's a greasy kitchen, factory floor, or hospital corridor. Contact us today to discuss your needs and discover how our production capabilities can support your safety goals.

Visual Guide

Related Products

- Advanced KPU Athletic Safety Shoe with Steel Toe Cap Anti-Slip Rotary Lacing System

- Safety Footwear Wholesale Manufacturer for Custom OEM/ODM Production

- Durable Rubber-Soled Utility Shoes for Wholesale & Custom Brand Manufacturing

- Wholesale Premium Waterproof Nubuck Safety Shoes Boots

- Premium Suede Sport Safety Shoes for Wholesale & Bulk Orders

People Also Ask

- What are the advantages and disadvantages of steel toe boots? A Guide to Maximum Protection vs. Comfort

- What factors should be checked when trying on safety shoes? Ensure Perfect Fit & Maximum Protection

- What is the significance of composite or steel toe protection in work boots? Ensure Maximum Foot Safety & Comfort

- What are the key safety features to consider when choosing work boots? Ensure Maximum Protection for Your Job

- What protection do work boots offer against sharp objects? Your Guide to Puncture-Resistant Footwear