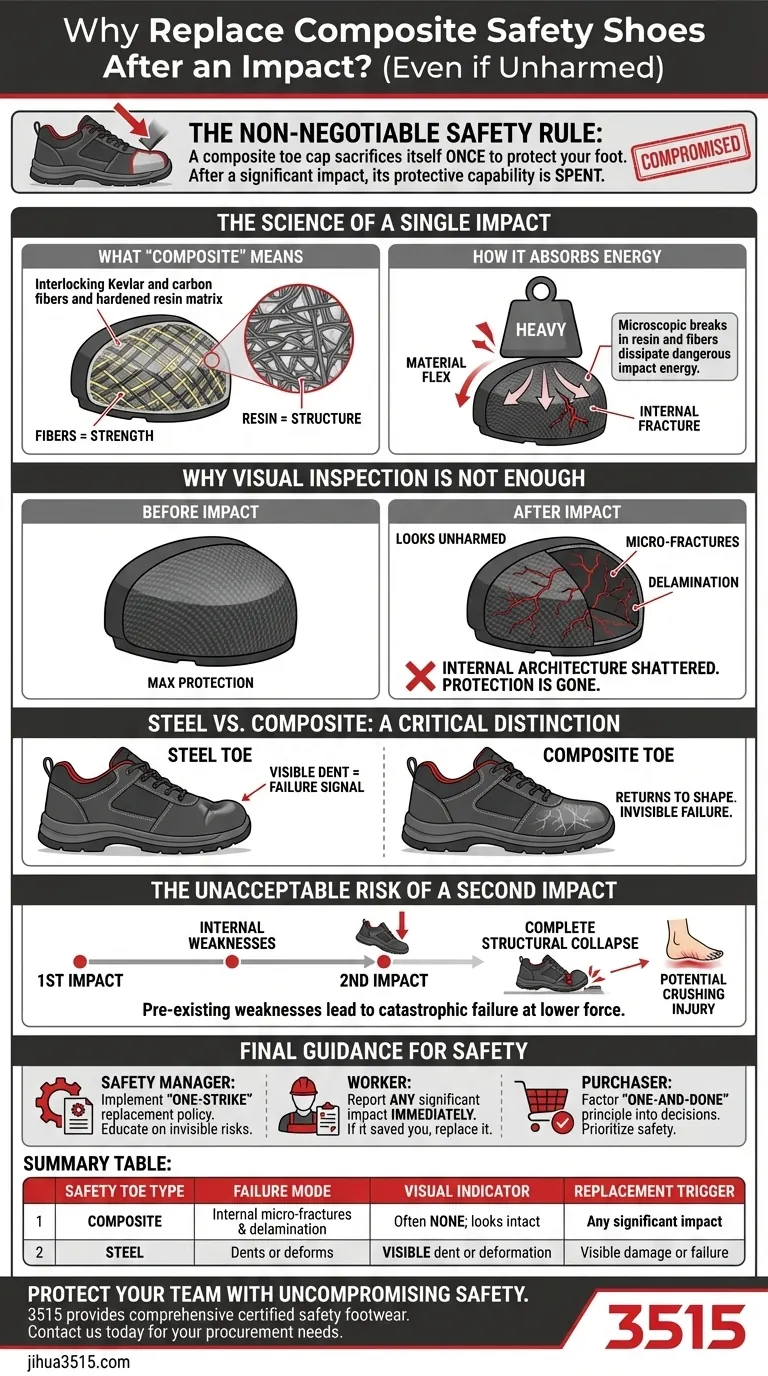

It is a non-negotiable safety rule: A composite safety shoe must be replaced after any significant impact because the event permanently compromises the internal structure of the protective toe cap. Even with no visible damage, microscopic fractures in the composite material mean it can no longer provide its rated level of protection against a future impact.

The core principle is simple: a composite toe cap is designed to sacrifice its structural integrity to protect your foot. This sacrifice happens once. After a significant impact, its protective capability is spent, regardless of its outward appearance.

The Science of a Single Impact

To understand why replacement is mandatory, you must first understand how these materials work. Unlike steel, a composite is not a single substance.

What "Composite" Really Means

A composite toe cap is made from multiple materials, typically strong fibers like Kevlar, carbon fiber, or fiberglass, all suspended in a hardened resin matrix.

Think of it like rebar inside concrete. The fibers provide immense strength, while the resin holds them in a rigid shape, allowing them to distribute the force of an impact.

How Composites Absorb Energy

When a heavy object strikes the toe, the energy is absorbed in two ways: the material flexes, and the internal structure strategically fractures.

These countless microscopic breaks in the resin and fibers are what dissipate the dangerous impact energy, preventing it from being transferred to your foot. This process is the material doing its job perfectly.

The "One and Done" Principle

This internal fracturing is permanent. The composite material has now been broken on a microscopic level.

While the toe cap may spring back to its original shape, its internal strength is gone. It has successfully absorbed one major impact, and its capacity to do so again is critically reduced.

Why Visual Inspection Is Not Enough

The most dangerous feature of a damaged composite toe is that it often looks perfectly fine. This creates a false sense of security that can lead to serious injury.

The Danger of Micro-Fractures

The damage is almost always internal. The resin develops micro-cracks, and the fibers can separate from the resin in a process called delamination.

You cannot see this damage. The surface may show only a minor scuff or no mark at all, while the internal architecture that protects you is shattered.

Steel vs. Composite: A Critical Distinction

This is the key difference between composite and steel toes. A steel toe will visibly dent or deform when it fails or is compromised. That dent is a clear, unambiguous signal that the boot must be replaced.

A composite toe is designed to return to its original shape, masking the catastrophic internal damage. Its failure is invisible.

The Unacceptable Risk of a Second Impact

If a shoe with a compromised composite toe is struck a second time, it will fail at a much lower level of force.

The pre-existing internal weaknesses provide an easy path for the new impact energy to travel, leading to a complete structural collapse and a potential crushing injury to the foot.

Final Guidance for Safety

When it comes to personal protective equipment (PPE), doubt must always be resolved in favor of safety. The integrity of your footwear is not a place for guesswork.

- If you are a safety manager: Implement a strict "one-strike" replacement policy for all safety footwear and educate your team on the invisible risks of post-impact composite toes.

- If you are a worker: You must report any significant impact to your safety toe immediately. Treat any event that makes you think, "I'm glad I was wearing safety shoes," as a trigger for replacement.

- If you are purchasing footwear: Factor this replacement rule into your decision. The lightweight and non-conductive benefits of composite toes are tied to this non-negotiable safety principle.

Never trust a composite safety shoe that has already taken a hit; its ability to protect you is gone.

Summary Table:

| Safety Toe Type | Failure Mode | Visual Indicator | Replacement Trigger |

|---|---|---|---|

| Composite | Internal micro-fractures & delamination | Often none; looks intact | Any significant impact |

| Steel | Dents or deforms | Visible dent or deformation | Visible damage or failure |

Protect your team with uncompromising safety. As a large-scale manufacturer, 3515 produces a comprehensive range of certified safety footwear for distributors, brand owners, and bulk clients. Ensure your workers are equipped with reliable PPE that meets the highest standards. Contact our experts today to discuss your safety footwear needs and procurement strategy.

Visual Guide

Related Products

- Premium KPU Athletic Safety Shoes for Wholesale

- Wholesale Leather Safety Boots with Customizable Protective Toe

- Premium Lightweight Safety Shoes for Wholesale & Bulk Orders

- Wholesale Durable Breathable Safety Boots Custom OEM Manufacturer

- Custom Safety Shoe Manufacturer for Wholesale & OEM Brands

People Also Ask

- How does the new EN ISO 20345 standard modify slip resistance markings? Understand the Simplified SR System

- What is the primary function of specialized protective footwear within the configuration of Level 3 PPE? Expert Insights

- How does the Factorial Survey method function in safety footwear evaluation? Optimize Your Product Performance

- What is the significance of standard compliance for safety equipment within a sustainable construction safety framework? Ensuring Reliable Protection & Mitigating Risk

- What are the common workplace dangers that can affect employees' feet? Protect Your Team from Top Hazards

- What are the safety standards for composite toe boots? Meet ASTM F2413 for Ultimate Protection

- What are the primary functions of Triboelectric Nanogenerators in safety shoes? Harnessing Energy & Smart Sensing

- What core protections do industrial-grade safety shoes provide? Safeguarding Gemstone Miners Against Critical Hazards