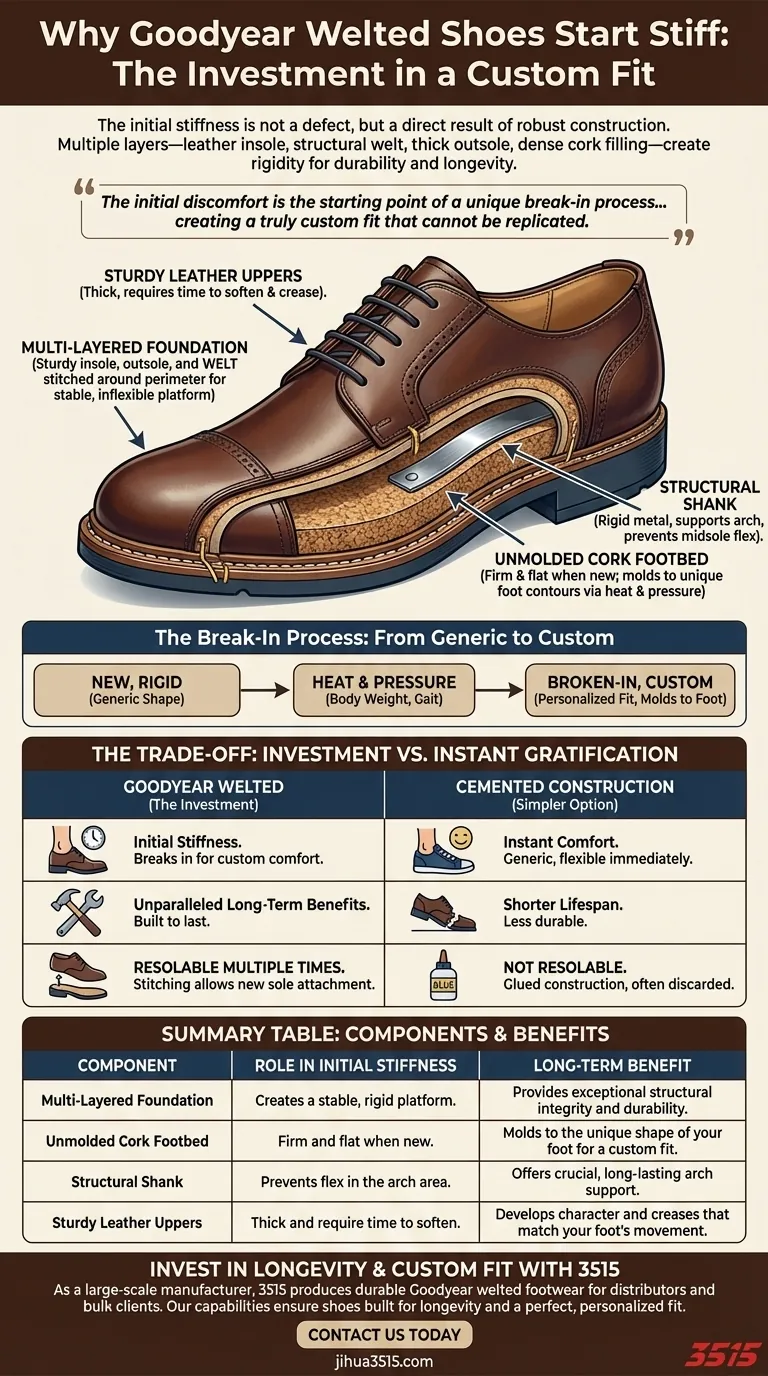

The initial stiffness of a Goodyear welted shoe is not a defect, but a direct result of its robust construction. The shoe's multiple layers—including a leather insole, a structural welt, a thick outsole, and a dense cork filling—are engineered for durability and longevity, which inherently creates rigidity when the shoe is new.

The initial discomfort of a Goodyear welted shoe is the starting point of a unique break-in process. This period is essential for the shoe's cork footbed and leather components to mold precisely to your foot, creating a truly custom fit that cannot be replicated by more flexible, mass-produced footwear.

The Anatomy of Initial Stiffness

The break-in period is best understood by examining the core components that need time to adapt to your foot. Each part contributes to the shoe's initial rigidity and its eventual custom comfort.

The Multi-Layered Foundation

A Goodyear welted shoe is built around a system of strong, separate layers. It features a sturdy insole, an outsole, and a strip of leather (the welt) stitched around the perimeter to hold everything together. This creates a very stable but inflexible platform right out of the box.

The Unmolded Cork Footbed

Between the insole and the outsole lies a cavity filled with granulated cork. When new, this cork is a firm, flat layer. Through the heat and pressure of your body weight and gait, this cork slowly compresses and molds to the unique contours of your foot, creating a personalized footbed.

The Structural Shank

A rigid metal shank is embedded between the insole and outsole. Its purpose is to provide structural support to the arch of your foot and prevent the shoe from flexing in the middle. While crucial for long-term support, it adds to the initial stiffness.

The Sturdy Leather Uppers

High-quality Goodyear welted shoes are made with thick, durable leather. Just like the sole, the uppers require a period of wear to soften and crease in a way that perfectly matches your foot's movement and flex points.

Understanding the Trade-Off: Investment vs. Instant Gratification

Choosing a Goodyear welted shoe involves a deliberate trade-off. You are sacrificing immediate, sneaker-like comfort for unparalleled long-term benefits.

The Purpose of the "Break-In"

The break-in period is an investment. It is the time during which the shoe transitions from a generic shape to one that is customized for you. This process is what owners of high-quality footwear refer to when they speak of shoes becoming "more comfortable with age."

The Benefit of a Resolable Design

The Goodyear welt construction is what allows the shoe to be resoled multiple times. Because the welt is stitched to the upper, a cobbler can remove the old sole and attach a new one without deconstructing the entire shoe. This durability is a direct consequence of its complex, rigid build.

The Contrast with Simpler Constructions

Many modern shoes use a "cemented" construction, where the sole is simply glued to the upper. These shoes are flexible and comfortable immediately but lack the durability and repairability of a Goodyear welt. They offer instant comfort at the expense of longevity.

Making the Right Choice for Your Goal

Understanding this initial discomfort allows you to select footwear that aligns with your priorities.

- If your primary focus is immediate, out-of-the-box comfort: A shoe with a cemented or more flexible construction may be a better initial choice.

- If your primary focus is long-term durability and a custom fit: The initial break-in period for a Goodyear welted shoe is a necessary and highly rewarding investment.

Ultimately, the stiffness of a new Goodyear welted shoe is the promise of future comfort and a testament to its quality.

Summary Table:

| Component | Role in Initial Stiffness | Long-Term Benefit |

|---|---|---|

| Multi-Layered Foundation | Creates a stable, rigid platform. | Provides exceptional structural integrity and durability. |

| Unmolded Cork Footbed | Firm and flat when new. | Molds to the unique shape of your foot for a custom fit. |

| Structural Shank | Prevents flex in the arch area. | Offers crucial, long-lasting arch support. |

| Sturdy Leather Uppers | Thick and require time to soften. | Develops character and creases that match your foot's movement. |

Ready to invest in footwear that molds to you and lasts for years?

As a large-scale manufacturer, 3515 produces a comprehensive range of durable Goodyear welted footwear for distributors, brand owners, and bulk clients. Our production capabilities ensure you receive shoes built for longevity and a perfect, personalized fit.

Contact us today to discuss your footwear needs and discover the 3515 advantage.

Visual Guide

Related Products

- Safety Footwear Wholesale Manufacturer for Custom OEM/ODM Production

- Custom OEM Training Shoes Wholesale Manufacturer Durable & Breathable

- Durable Rubber Sole Outdoor Shoes Wholesale & Custom Manufacturing

- Durable Leather Safety Boots for Wholesale & Custom OEM Manufacturing

- Wholesale Women's Leather Derby Shoes Custom Factory Production

People Also Ask

- What are the primary protective functions of professional Safety Boots within the automotive maintenance process?

- How do professional construction boots improve operational efficiency? Boost Site Productivity with Advanced Footwear

- Is it normal to wear shoes in the house? A Guide to Hygiene, Comfort & Culture

- What are the differences between steel toe, composite toe, and alloy toe Wellington boots? Choose the Right Safety Toe for Your Job

- How do safety shoes contribute to cost savings for companies? A Strategic Investment in Risk and Cost Management