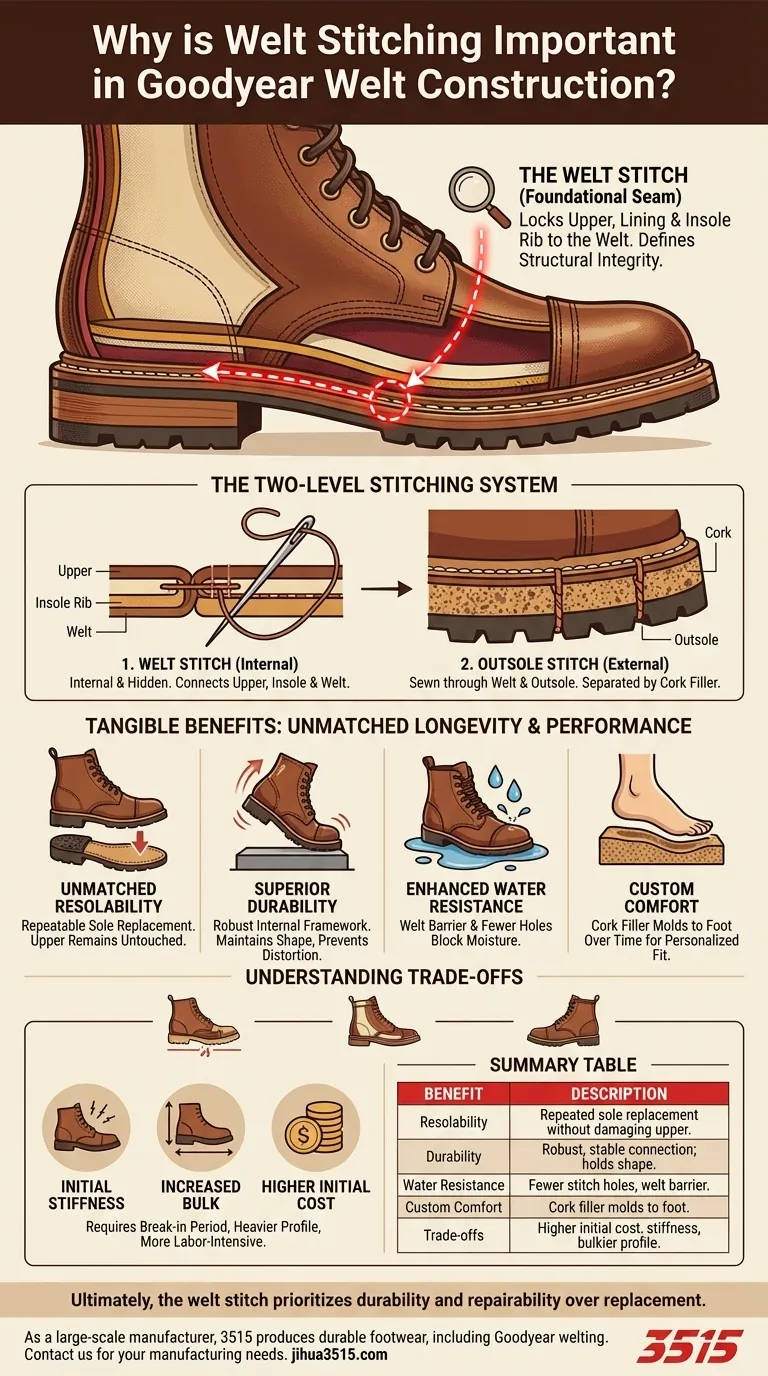

At its core, the welt stitch is the foundational seam in Goodyear welt construction. It is the critical stitch that locks the shoe's upper, lining, and insole rib to a separate strip of leather known as the welt. This single, robust connection creates a stable platform to which the outsole is later attached, defining the shoe's entire structural integrity.

The importance of the welt stitch extends far beyond simply holding parts together. It is the architectural linchpin that makes a shoe durable, water-resistant, and, most importantly, repeatedly repairable for a lifetime of use.

How the Welt Stitch Defines the Shoe's Architecture

To understand the welt stitch, you must first understand that Goodyear welt construction is a two-level system. The welt stitch is the internal, hidden connection, while a second, separate stitch attaches the sole.

The Insole as the Foundation

Every Goodyear welted shoe begins with a robust insole. A vertical ridge of material, known as the insole rib, is attached to the underside of this insole. This rib serves as the primary anchor point for the entire shoe.

The Welt as the Bridge

The welt is a durable strip of leather that runs along the perimeter of the shoe. Its sole purpose is to act as a bridge, connecting the shoe's upper to its eventual outsole without directly puncturing the insole.

The Two-Level Stitching Process

The welt stitch is the first and most critical step. A strong thread is stitched horizontally through the shoe's upper, the insole rib, and the welt itself, locking them all together.

Once this is complete, a cavity is created between the insole and the outsole. This space is filled with cork for cushioning and support. Finally, a second, separate stitch—the outsole stitch—is sewn vertically through the welt and the outsole, completing the construction.

The Tangible Benefits of This System

The genius of the welt stitch is in the functional benefits it enables. This indirect method of sole attachment is what separates Goodyear construction from simpler, less durable methods.

Unmatched Resolability and Longevity

This is the primary advantage. To replace a worn-out sole, a cobbler simply cuts the outsole stitch and removes the old sole. The original welt stitch and the shoe's upper remain completely untouched and structurally sound. A new sole can then be sewn onto the existing welt, a process that can be repeated many times.

Superior Durability and Stability

The welt stitch creates an incredibly strong and stable connection between all key components of the shoe. This robust internal framework helps the shoe maintain its shape and provides a solid platform for your foot, preventing twisting and distortion over years of wear.

Enhanced Water Resistance

Because the outsole stitch does not pass through to the inside of the shoe, there are fewer entry points for water. The welt itself acts as an additional barrier between the upper and the sole, further preventing moisture from seeping in from the ground.

A Foundation for Custom Comfort

The cavity created by the welt construction is filled with a layer of cork filler. Over time, the heat and pressure from your foot cause this cork to compress and mold to your specific foot shape, creating a custom-fit footbed that is unique to you.

Understanding the Trade-offs

While highly effective, the Goodyear welt method is not without its compromises. True objectivity requires acknowledging its inherent characteristics.

Initial Stiffness

The multiple layers—insole, cork, midsole, outsole—and the robust stitching result in a shoe that is often quite stiff out of the box. Goodyear welted footwear requires a "break-in" period for the materials to soften and conform to your foot.

Increased Bulk and Profile

The external welt and the two-level stitching add material and space to the shoe's perimeter. This results in a slightly bulkier and heavier profile compared to more streamlined constructions where the sole is glued or stitched directly to the upper.

Higher Initial Cost

Goodyear welt construction is a more complex, labor-intensive process that requires skilled craftsmanship and more raw materials. This is directly reflected in a higher upfront cost compared to simpler construction methods.

Making the Right Choice for Your Goal

Understanding the role of the welt stitch allows you to make an informed decision based on what you value most in your footwear.

- If your primary focus is longevity and long-term value: The unparalleled resolability enabled by the welt stitch makes Goodyear welted shoes a superior investment.

- If your primary focus is immediate, lightweight comfort: You may find the initial stiffness and weight of this construction to be a significant drawback.

- If your primary focus is a sleek, low-profile design: The inherent bulk of the welt may not align with your aesthetic goals.

Ultimately, the welt stitch is the heart of a construction method designed for those who prioritize durability and the ability to repair, rather than replace.

Summary Table:

| Benefit | Description |

|---|---|

| Resolability | Allows for repeated sole replacement without damaging the upper. |

| Durability | Creates a robust, stable connection between the upper, insole, and welt. |

| Water Resistance | Fewer stitch holes and a leather welt barrier help keep moisture out. |

| Custom Comfort | Cork filler molds to your foot over time for a personalized fit. |

| Trade-offs | Higher initial cost, initial stiffness, and a bulkier profile. |

As a large-scale manufacturer, 3515 produces a comprehensive range of durable footwear for distributors, brand owners, and bulk clients. Our production capabilities encompass all types of shoes and boots, including time-tested constructions like Goodyear welting. We can help you develop a line built for longevity and customer satisfaction.

Contact us today to discuss your manufacturing needs and how we can bring value to your brand.

Visual Guide

Related Products

- Safety Footwear Wholesale Manufacturer for Custom OEM/ODM Production

- Wholesale Leather Work Boots with Customizable Wedge Sole for Brands

- Wholesale Safety Footwear Manufacturer for Bulk & Custom OEM Orders

- Durable Goodyear Welt Leather Work Boots for Wholesale & Private Label

- Durable Leather Work Boots for Wholesale & Custom OEM Manufacturing

People Also Ask

- How do safety shoes contribute to cost savings for companies? A Strategic Investment in Risk and Cost Management

- How do industrial safety shoes provide protection for personnel? Safeguard Your Team from Heavy Crane Hazards

- What core protection features do industrial-grade Safety Shoes provide? Key Safety Standards for Infrastructure Sites

- What are the cultural perspectives on wearing shoes in the house? A Guide to Home Etiquette & Hygiene

- What cultural and environmental considerations are tied to wearing shoes indoors? Balance Hygiene, Tradition, and Foot Health