At its core, traction is essential in work boots because it provides the critical grip needed to prevent slips, trips, and falls. These are among the most common and dangerous workplace hazards, and a high-traction sole is the first line of defense against them, ensuring stable footing on unpredictable surfaces and significantly reducing the risk of serious injury.

The real purpose of a work boot isn't just to cover your foot; it's to create a stable, protective foundation between you and your work environment. While features like toe protection guard against impacts, traction is the active feature that keeps you upright and in control.

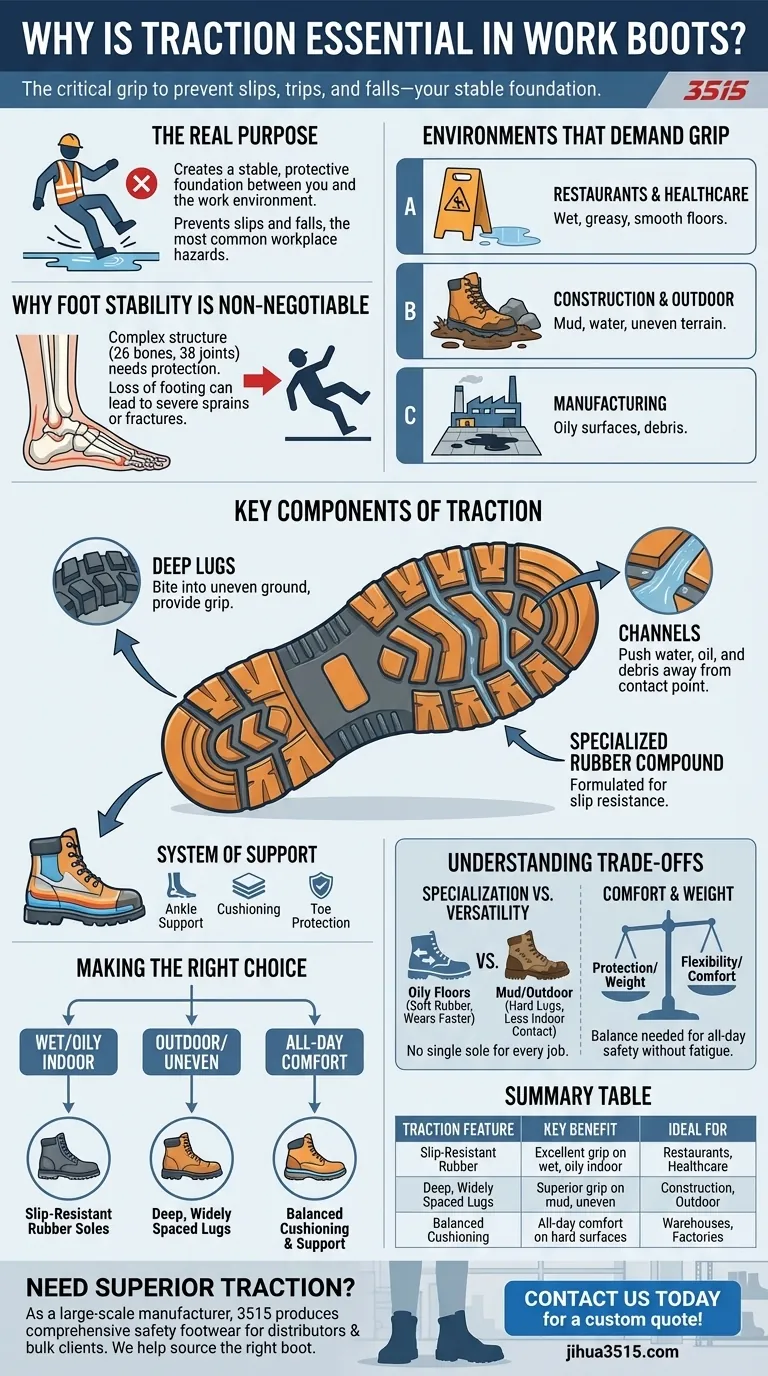

Why Foot Stability is Non-Negotiable

A work boot is a piece of personal protective equipment (PPE) designed to mitigate risk in hazardous environments. Industries like construction, manufacturing, and healthcare all present unique dangers where a loss of footing can be catastrophic.

The Anatomy of a Fall

The human foot is a complex structure with 26 bones and 38 joints, all working together to provide balance and mobility. An injury to any part of this system can be debilitating.

A simple slip can cause severe sprains, fractures, or worse, especially if the worker is carrying heavy materials or operating machinery.

Environments That Demand Grip

Certain workplaces have a constant risk of slick surfaces. Restaurants deal with grease and spills, construction sites have mud, water, and uneven terrain, and hospitals require constant cleaning that leaves floors wet.

In these contexts, standard footwear is inadequate. Work boots with specialized outsoles are engineered specifically to channel away liquids and bite into the ground for a secure grip.

The Key Components of a Protective Work Boot

Traction is a critical piece of a larger safety system. A truly effective work boot integrates several features that work together to protect the wearer.

The Outsole: Where Traction Happens

The outsole is the part of the boot that contacts the ground. Its design is paramount for safety.

Look for deep lugs (the indentations and patterns on the sole) and channels designed to push water, oil, and debris away from the point of contact. The material itself, often a specialized rubber compound, is also formulated for slip resistance.

Beyond the Sole: A System of Support

While the outsole provides grip, other features ensure the foot remains stable and protected.

Ankle support prevents twists and sprains, while proper cushioning absorbs shock and reduces fatigue, which can lead to clumsiness and accidents. Toe protection, often a steel or composite cap, guards against crushing and impact injuries.

Understanding the Trade-offs

Not all high-traction boots are created equal, and choosing the right one involves understanding the compromises.

Specialization vs. Versatility

A boot designed for oily factory floors might use a soft, sticky rubber that provides excellent grip indoors but wears out quickly on abrasive surfaces like concrete or gravel.

Conversely, a boot with hard, deep lugs for mud and outdoor terrain might feel clumsy and offer less surface-area contact on a smooth, flat floor. There is no single "best" sole for every job.

Comfort and Weight

Historically, the safest boots were often the heaviest and most rigid. Modern materials have improved this, but there can still be a trade-off.

Aggressive, thick outsoles add weight and can reduce flexibility. It's crucial to find a balance where the boot provides necessary traction without causing undue fatigue over a long shift.

Making the Right Choice for Your Goal

Selecting the right boot means matching its features to your specific work environment.

- If your primary focus is working on wet or oily indoor surfaces: Prioritize boots with slip-resistant rubber soles that have many fine-edged tread patterns to maximize surface contact.

- If your primary focus is outdoor work on uneven terrain: Look for boots with deep, widely spaced lugs that can dig into soft ground and shed mud easily.

- If your primary focus is all-day comfort on hard, flat surfaces: Seek a boot that balances a durable, slip-resistant sole with excellent cushioning and arch support to fight fatigue.

Ultimately, choosing a work boot with the right traction is a foundational decision for your personal safety on the job.

Summary Table:

| Traction Feature | Key Benefit | Ideal For |

|---|---|---|

| Slip-Resistant Rubber Soles | Excellent grip on wet, oily indoor surfaces | Restaurants, healthcare, manufacturing |

| Deep, Widely Spaced Lugs | Superior grip on mud and uneven terrain | Construction, landscaping, outdoor work |

| Balanced Cushioning & Support | All-day comfort on hard, flat surfaces | Warehouses, factories, long shifts |

Need work boots with superior traction for your team? As a large-scale manufacturer, 3515 produces a comprehensive range of safety footwear for distributors, brand owners, and bulk clients. Our production capabilities encompass all types of shoes and boots, including specialized designs for oily floors, uneven terrain, and all-day comfort. We can help you source the right protective footwear to keep your workforce safe and productive. Contact us today for a custom quote!

Visual Guide

Related Products

- Premium Wholesale Wheat Nubuck Safety Boot with Rapid Lacing System

- Premium Grain Leather Safety Boots for Bulk Supply

- Custom Wholesale Leather Safety Boots Direct Factory Manufacturing

- Customizable Anti-Smash Safety Boots for Wholesale & Private Label Manufacturing

- Premium Wholesale Waterproof Safety Boots High Performance Protection for Industrial Markets

People Also Ask

- What is the crucial practice for maximizing the durability of cowboy boots? Rotate Your Boots to Extend Their Lifespan

- How do cowboy boots enhance comfort for long workdays? Unlock All-Day Support & Stability

- What factors should be considered when choosing the best work boots for a specific job? Match Your Boot to Your Work Hazards

- How should work boots with zips be cared for? Extend Boot Life with Proper Zip Maintenance

- What additional protective footwear feature might be beneficial for construction workers in cold climates? Choose Composite Toe for Superior Warmth

- Do work boot manufacturers use the same construction methods? Choose the Right Foundation for Your Job

- What are the key features of logger boots? A Guide to Unmatched Stability & Safety

- How can you ensure a comfortable fit when selecting oilfield work boots? A Guide to All-Day Comfort & Safety