The short answer is that smooth leather is used for the upper portion of a fire boot primarily for function and mobility. This design prevents the boot from catching or snagging on turnout pants, allowing for smoother, unrestricted movement when crouching, climbing, or crawling.

The construction of a fire boot is a deliberate engineering choice, balancing extreme durability with critical mobility. Using smooth leather on the upper shaft is a key part of this strategy, prioritizing a seamless integration with your gear over the heavy-duty abrasion resistance needed elsewhere.

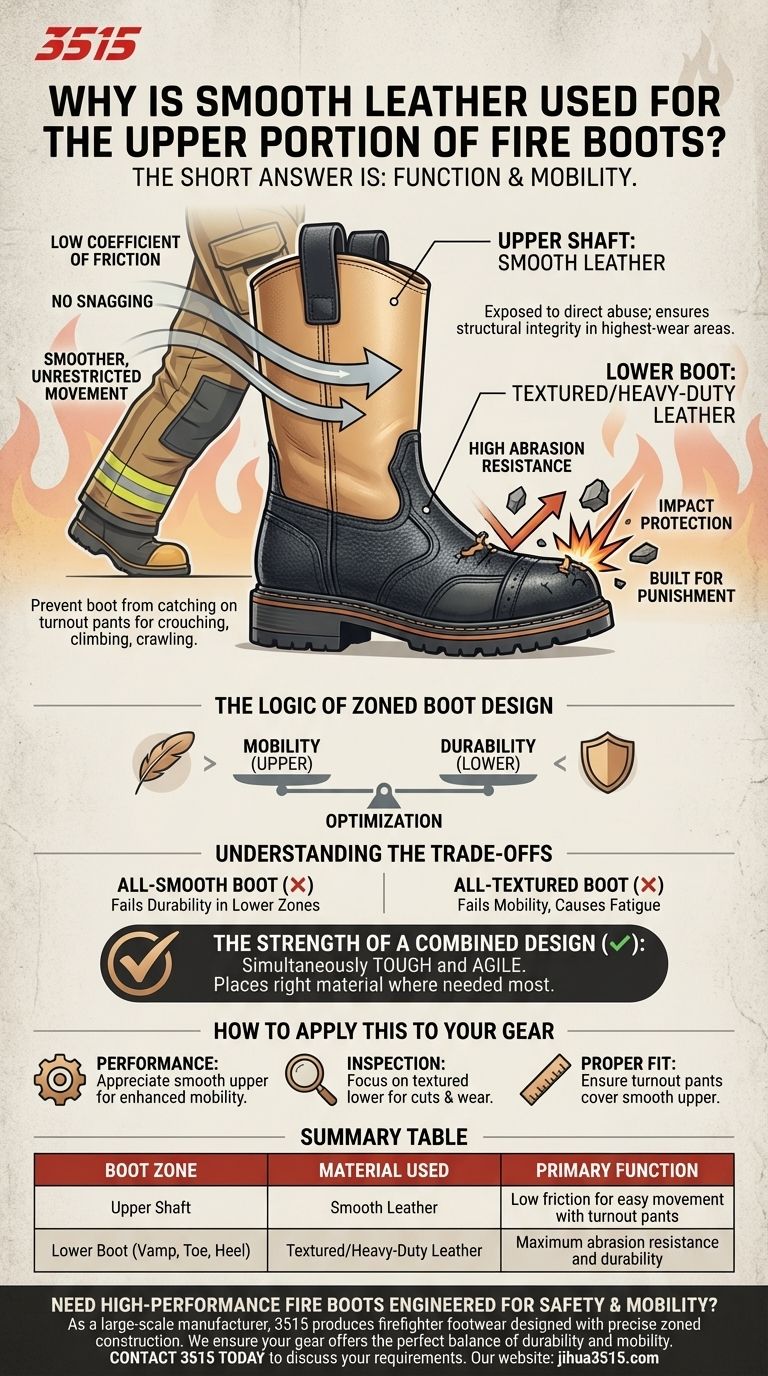

The Logic of Zoned Boot Design

A modern fire boot isn't made from a single, uniform material. It's a carefully assembled system where different materials are placed in specific zones based on the unique demands of that area. The use of smooth leather on the upper shaft is a perfect example of this purpose-driven design.

The Upper Shaft: Prioritizing Mobility

The upper portion of your boot lives almost entirely underneath your bunker pants. Its primary job is to flex with your leg and interact seamlessly with your gear.

Smooth leather excels here because its surface has a low coefficient of friction. This allows the leg of your turnout pants to slide over it effortlessly.

This prevents the material from bunching or snagging, which could otherwise restrict your movement at critical moments.

The Lower Boot: Built for Punishment

In stark contrast, the lower part of the boot—the vamp, toe, and heel—is constantly exposed to direct abuse.

This area is often made from a thicker, heavier-grained, or textured leather. This provides the immense abrasion resistance needed when kicking through debris, navigating rubble, and absorbing direct impacts.

Placing this heavy-duty material on the lower section ensures the structural integrity of the boot is maintained in the highest-wear areas.

Understanding the Trade-offs

Choosing the right material for each zone involves balancing competing needs. No single material is perfect for the entire boot, which is why a hybrid approach is the standard for high-performance footwear.

The Flaw of an All-Smooth Boot

A boot made entirely of smooth leather would be more flexible, but it would fail catastrophically on the fireground. The lower sections would quickly be shredded by scrapes and scuffs, compromising the boot's protective capabilities.

The Problem with an All-Textured Boot

Conversely, a boot made entirely of heavy, textured leather would be incredibly durable but functionally clumsy. The upper shaft would constantly catch on turnout pants, impeding movement, and the added stiffness would cause premature fatigue.

The Strength of a Combined Design

The dual-leather design is not a compromise; it's an optimization. It places the right material exactly where it is needed most, creating a boot that is simultaneously tough and agile.

How to Apply This to Your Gear

Understanding this design principle helps you better assess and maintain your equipment.

- If your primary focus is performance: Appreciate that the smooth upper is a feature designed to enhance your mobility and prevent your gear from fighting you.

- If your primary focus is equipment inspection: Recognize that the lower, textured areas are designed for abuse and should be the primary focus when checking for cuts, punctures, and excessive wear.

- If your primary focus is proper fit: Ensure your turnout pants are the correct length to properly cover the smooth leather upper, allowing the system to work as intended.

Ultimately, every element of your boot is engineered to keep you safe and effective, and the use of smooth leather is a critical piece of that equation.

Summary Table:

| Boot Zone | Material Used | Primary Function |

|---|---|---|

| Upper Shaft | Smooth Leather | Low friction for easy movement with turnout pants |

| Lower Boot (Vamp, Toe, Heel) | Textured/Heavy-Duty Leather | Maximum abrasion resistance and durability |

Need High-Performance Fire Boots Engineered for Safety and Mobility?

As a large-scale manufacturer, 3515 produces a comprehensive range of footwear for distributors, brand owners, and bulk clients. Our production capabilities encompass all types of professional boots, including firefighter footwear designed with the precise zoned construction detailed above. We ensure your gear offers the perfect balance of durability where it counts and the smooth mobility needed in high-stakes situations.

Contact 3515 today to discuss your fire boot requirements and benefit from our expert manufacturing solutions.

Visual Guide

Related Products

- High Performance Fire-Retardant Waterproof Safety Boots

- Safety Footwear Wholesale Manufacturer for Custom OEM/ODM Production

- Wholesale Waterproof Tactical Boots Custom Suede & High-Traction Soles

- Durable Leather Tactical Boots Wholesale & Custom Manufacturing for Brands

- Premium Grain Leather Safety Boots for Bulk Supply

People Also Ask

- What are the key factors to consider when choosing police boots? Ensure Safety, Comfort & Performance

- What types of protection should law enforcement boots offer? Essential Safety Features for Officers

- What are the key considerations when selecting firefighting boots? Ensure Optimal Safety and Performance

- What types of emergency scenarios are NFPA boots suitable for? Your Guide to Life-Saving Footwear

- Why is it important to break in new police footwear? Ensure Peak Performance and Prevent Injury

- Why is the weight of police boots an important consideration? Balance Fatigue & Protection for Peak Performance

- What should be considered when choosing police tactical boots? The Ultimate Guide for Safety & Performance

- What materials are commonly used for the upper part of police boots? A Guide to Durability & Performance