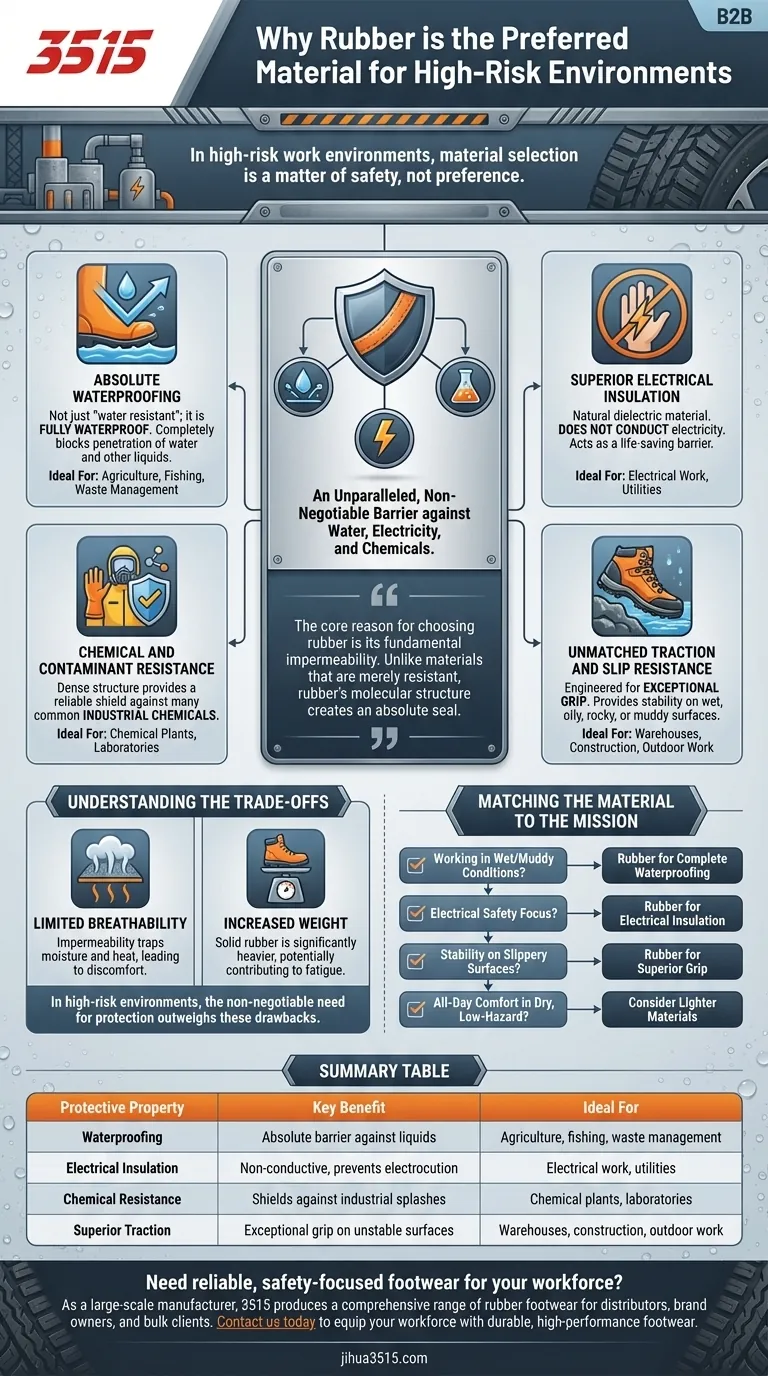

In high-risk work environments, material selection is a matter of safety, not preference. Rubber is the preferred material for specific jobs because it provides an unparalleled, non-negotiable barrier against three critical hazards: water, electricity, and chemicals, while also delivering superior traction on unstable surfaces.

The core reason for choosing rubber is its fundamental impermeability. Unlike materials that are merely resistant, rubber's molecular structure creates an absolute seal, making it the definitive choice when exposure to liquids or electrical currents is a primary and unavoidable workplace hazard.

The Core Protective Properties of Rubber

To understand why rubber is essential, we must look at its inherent physical properties. These are not features added on; they are part of what the material is.

Absolute Waterproofing

Rubber is not just "water-resistant"; it is fully waterproof. It completely blocks the penetration of water and other liquids.

This makes it indispensable for roles in agriculture, fishing, or waste management, where prolonged exposure to wet and muddy conditions is the norm.

Superior Electrical Insulation

Rubber is a natural dielectric material, meaning it does not conduct electricity. This property is critical for anyone working in electrically hazardous environments.

It acts as a barrier between the worker and a potential electrical current, dramatically reducing the risk of severe injury or electrocution.

Chemical and Contaminant Resistance

The dense structure of rubber also provides a reliable shield against many common industrial chemicals and contaminants.

This makes it a vital component of personal protective equipment (PPE) in settings where chemical splashes or exposure are a daily risk.

Unmatched Traction and Slip Resistance

Rubber outsoles are engineered for exceptional grip. They provide stability and prevent falls on wet, oily, rocky, or muddy surfaces.

Hiker-style rubber outsoles, for example, are specifically designed to balance this high traction with comfort, making them suitable for outdoor jobs, warehouses, and factory floors requiring slip and oil resistance.

Understanding the Trade-offs

No material is perfect for every application. Choosing rubber involves accepting a specific set of compromises in exchange for its protective benefits.

Limited Breathability

The same impermeability that makes rubber waterproof also means it is not breathable. It traps moisture and heat, which can lead to discomfort during long periods of wear.

Increased Weight

Compared to many modern synthetic materials, solid rubber is significantly heavier. This can contribute to fatigue over the course of a demanding workday.

The Context for Compromise

In the environments where rubber is required, these trade-offs are deemed acceptable. The non-negotiable need for protection from water, electricity, or chemicals far outweighs the drawbacks of reduced breathability and increased weight.

Matching the Material to the Mission

Choosing the right protective material requires a clear-eyed assessment of the primary hazards you face daily.

- If your primary focus is working in wet or muddy conditions: Rubber's complete waterproofing is essential for keeping you dry and preventing related health issues.

- If your primary focus is electrical safety: The natural insulating properties of rubber provide a critical, life-saving barrier against electric shock.

- If your primary focus is stability on slippery surfaces: High-traction rubber outsoles offer superior grip and oil resistance that other materials cannot match.

- If your primary focus is all-day comfort in a dry, low-hazard environment: You may be better served by lighter, more breathable materials, as the intense protective features of rubber would be unnecessary.

Ultimately, understanding the unique, inherent properties of rubber empowers you to make an informed decision based on safety, not just comfort.

Summary Table:

| Protective Property | Key Benefit | Ideal For |

|---|---|---|

| Waterproofing | Absolute barrier against liquids | Agriculture, fishing, waste management |

| Electrical Insulation | Non-conductive, prevents electrocution | Electrical work, utilities |

| Chemical Resistance | Shields against industrial splashes | Chemical plants, laboratories |

| Superior Traction | Exceptional grip on unstable surfaces | Warehouses, construction, outdoor work |

Need reliable, safety-focused footwear for your workforce?

As a large-scale manufacturer, 3515 produces a comprehensive range of rubber footwear for distributors, brand owners, and bulk clients. Our production capabilities encompass all types of safety shoes and boots, engineered to provide the critical protection your team needs in high-risk environments.

Contact us today to discuss your specific requirements and discover how we can equip your workforce with durable, high-performance footwear.

Visual Guide

Related Products

- Premium Flame-Retardant Waterproof Safety Boots and Shoes

- Safety Footwear Wholesale Manufacturer for Custom OEM/ODM Production

- Durable Rubber Sole Outdoor Shoes Wholesale & Custom Manufacturing

- Custom OEM Training Shoes Wholesale Manufacturer Durable & Breathable

- Advanced KPU Athletic Safety Shoe with Steel Toe Cap Anti-Slip Rotary Lacing System

People Also Ask

- How do employer replacement rules impact the use of work boots? A Guide to Proactive Safety

- What are the proper steps for wearing pull-on work boots? Get the Perfect Fit for Safety & Comfort

- What comfort features should be considered when choosing mining boots? Prioritize Safety and Endurance

- What alternative solutions exist for protecting leather boots during hazmat responses? Preserve Your Gear & Budget

- Why should you avoid using products with lanolin on leather boots? Preserve Boot Structure and Durability

- What are the advantages of full-grain leather boots? Unmatched Durability & Custom Fit

- How do social media interactivity features enhance procurement engagement for tactical and work boots?

- Why is it important to care for farm boots? Protect Your Investment and Safety on the Job