Effective moisture management in firefighting boots is a critical safety feature, not a comfort accessory. It is a two-part system designed to protect a firefighter's feet from both internal threats like sweat and external hazards like water and chemicals. This system is essential for maintaining foot health, ensuring focus during critical operations, and preserving the structural integrity of the boot itself.

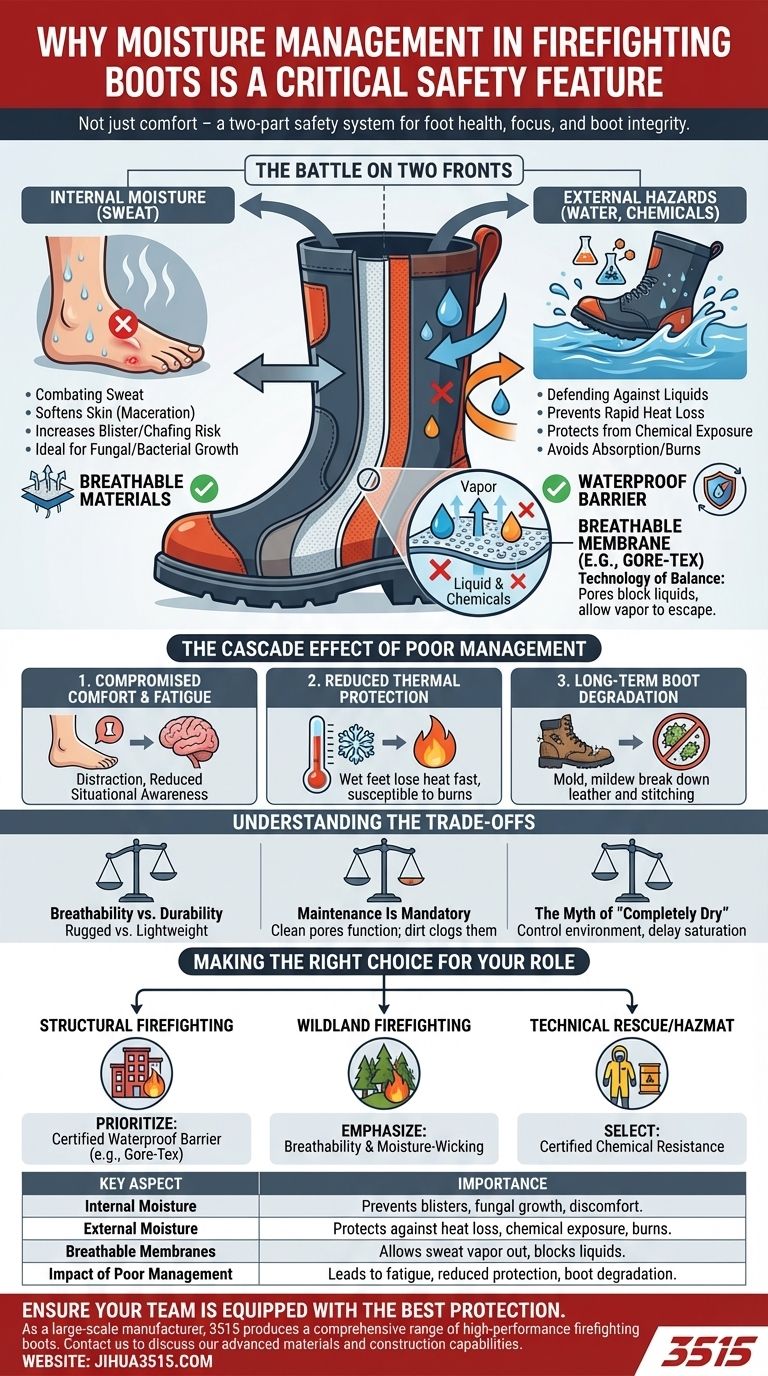

The core challenge of moisture management is a battle on two fronts: letting internal sweat vapor escape while blocking external liquid hazards from entering. Failing on either front directly compromises a firefighter's safety, performance, and endurance.

The Two Fronts of Moisture Control

A firefighter's feet are constantly under siege from moisture. The strategy for protecting them must account for threats coming from both inside and outside the boot.

Combating Internal Moisture: The Problem of Sweat

During intense physical exertion, the feet produce a significant amount of sweat. If this moisture is trapped, it creates a cascade of problems.

Trapped sweat softens the skin, a condition known as maceration. This dramatically increases the risk of friction-related injuries like blisters and chafing, which can be debilitating during a long incident.

Furthermore, damp socks and skin create an ideal environment for fungal and bacterial growth, leading to long-term health issues and odor. Breathable materials are the solution, allowing hot, moist air to escape.

Defending Against External Hazards: The Waterproof Barrier

Firefighters operate in environments saturated with water, foam, and potentially hazardous chemicals. A boot's outer layer must be a reliable barrier against these liquids.

This waterproof lining prevents external moisture from soaking the foot, which could otherwise lead to rapid heat loss and increased risk of cold-related injuries.

Crucially, this barrier also protects against chemical exposure. Contaminated liquids can cause chemical burns or be absorbed through the skin, and a compromised boot puts the firefighter at direct risk.

The Technology of Balance: Breathable Membranes

Modern boots often solve this two-front problem with advanced materials like Gore-Tex. These membranes contain pores that are too small for liquid water molecules to pass through, but large enough for water vapor (sweat) to escape.

This allows the boot to be both waterproof and breathable, providing a comprehensive moisture management solution.

The Cascade Effect of Poor Moisture Management

Failing to control moisture inside a boot does more than just make your feet uncomfortable. It triggers a series of negative consequences that impact overall performance and safety.

Compromised Comfort and Increased Fatigue

Wet, uncomfortable feet are a major distraction. Over the course of a long shift, this discomfort contributes significantly to physical and mental fatigue, reducing a firefighter's situational awareness and decision-making ability.

Reduced Thermal Protection

Water is an excellent conductor of heat. A foot that is wet from sweat or external water will lose heat much more quickly in cold conditions and is more susceptible to heat transfer and burns in high-temperature environments. Dry feet are better insulated feet.

Long-Term Boot Degradation

Constant dampness is destructive to the boot itself. Moisture promotes the growth of mold and mildew, which can break down leather, stitching, and adhesives over time. Proper drying and care, part of a good moisture management routine, are essential to maximizing the lifespan of this critical piece of gear.

Understanding the Trade-offs

No single boot is perfect for every scenario. Understanding the inherent compromises in design is key to selecting the right gear.

Breathability vs. Durability

Often, the most breathable materials are not the most rugged. A heavy, all-rubber boot offers maximum waterproof and chemical protection but very little breathability. A lighter leather or synthetic boot may offer superior breathability for wildland use but less resistance to abrasion and punctures.

The Myth of "Completely Dry"

In the most extreme conditions, some moisture buildup is inevitable. The goal of moisture management is to control the environment inside the boot, not to create an impossible-to-maintain vacuum. Effective systems significantly delay the onset of saturation and speed up drying time.

Maintenance Is Mandatory

Waterproof and breathable membranes rely on being clean to function properly. Pores clogged with dirt, oil, and grime cannot transport moisture vapor, rendering the breathable technology useless. Regular cleaning is not just for appearance; it is essential for performance.

Making the Right Choice for Your Role

The optimal approach to moisture management depends entirely on your primary operational environment.

- If your primary focus is structural firefighting: Prioritize a certified waterproof barrier like Gore-Tex to protect against water, foam, and chemical exposure from external sources.

- If your primary focus is wildland firefighting: Emphasize breathability and a moisture-wicking lining to manage the immense sweat produced during long hours of physically demanding work.

- If your primary focus is technical rescue or hazmat: Select boots with certified chemical resistance as the primary feature, ensuring the waterproof barrier can withstand hazardous materials.

Ultimately, managing moisture in your boots is about managing risk, allowing you to focus on the mission, not your feet.

Summary Table:

| Key Aspect | Importance |

|---|---|

| Internal Moisture (Sweat) | Prevents blisters, fungal growth, and discomfort. |

| External Moisture (Water/Chemicals) | Protects against heat loss, chemical exposure, and burns. |

| Breathable Membranes (e.g., Gore-Tex) | Allows sweat vapor out while blocking liquids from entering. |

| Impact of Poor Management | Leads to fatigue, reduced thermal protection, and boot degradation. |

Ensure your team is equipped with the best protection. As a large-scale manufacturer, 3515 produces a comprehensive range of high-performance firefighting boots for distributors, brand owners, and bulk clients. Our expertise in advanced materials and construction ensures superior moisture management tailored to your specific operational needs—from structural firefighting to wildland and hazmat. Contact us today to discuss how our production capabilities can deliver the durable, reliable footwear your customers depend on.

Visual Guide

Related Products

- High Performance Fire-Retardant Waterproof Safety Boots

- Premium Grain Leather Safety Boots for Bulk Supply

- Wholesale Waterproof Tactical Boots Custom Suede & High-Traction Soles

- Customizable Anti-Smash Safety Boots for Wholesale & Private Label Manufacturing

- Custom Wholesale Leather Safety Boots Direct Factory Manufacturing

People Also Ask

- What are the differences between wildland and structural firefighting boots? A Guide to Choosing the Right Gear

- How does heat affect leather in fire boots? Understanding Degradation for Maximum Safety

- How can aftermarket insoles improve police footwear? Enhance Comfort & Stability for Long Shifts

- How can officers ensure a proper fit for their police footwear? Get the Perfect Fit for Your Shift

- What are the benefits of roughout leather in fire boots? Unmatched Durability for the Fireground

- What are NFPA boots designed for? Ultimate Protection for Firefighters & First Responders

- What are the key features to look for in police tactical boots? A Guide to Safety, Durability & Comfort

- Why is it important to rotate between two pairs of police boots? Extend Lifespan & Protect Your Health