It is not advisable to store work boots for long periods because a chemical process called hydrolysis will cause their soles to disintegrate. This natural aging process specifically affects boots with Polyurethane (PU) soles, where moisture in the air breaks down the material's chemical bonds, making it brittle and prone to crumbling apart, often with no advance warning.

The core issue is that Polyurethane (PU), a material prized for comfort in boot soles, has an inherent vulnerability to moisture. Over time, this causes an irreversible chemical breakdown, meaning your boots have a limited shelf life whether you wear them or not.

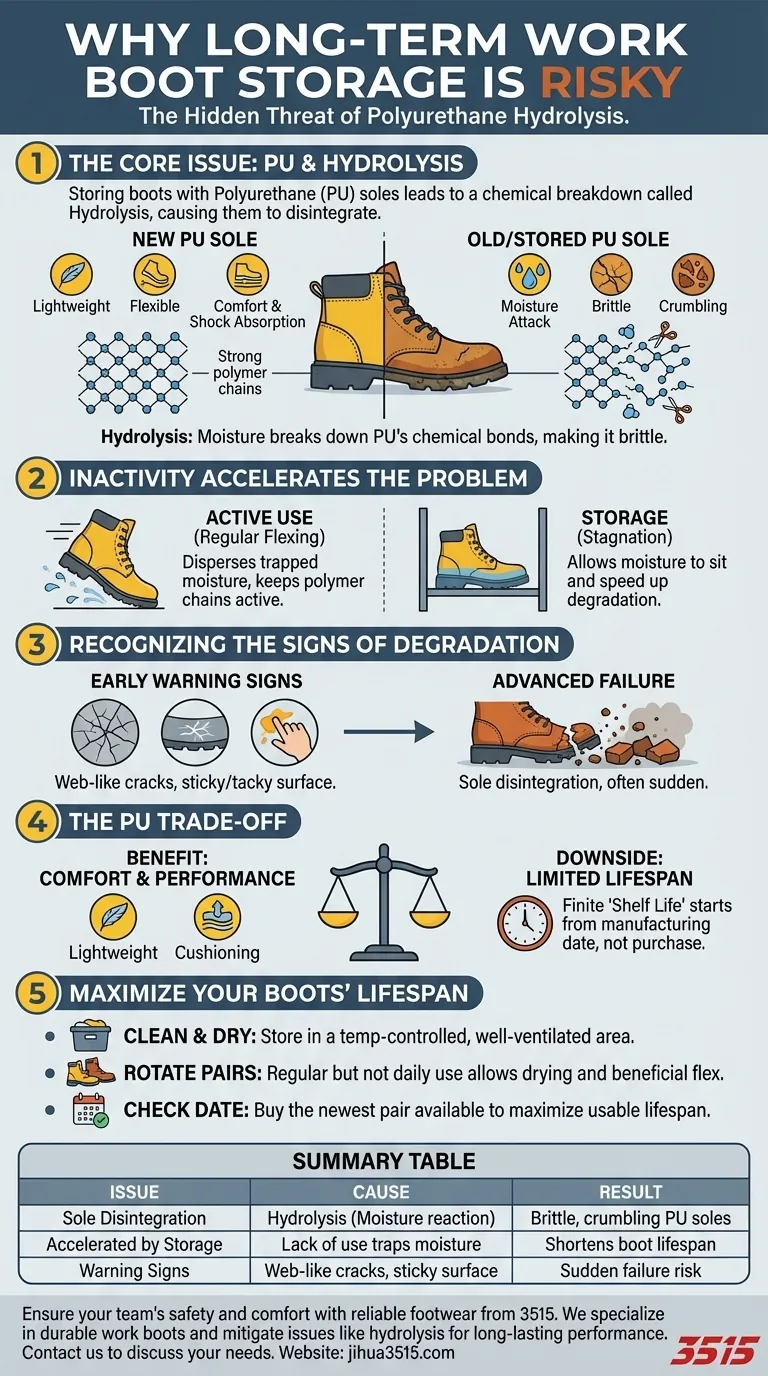

The Hidden Culprit: Polyurethane and Hydrolysis

To protect your investment and ensure your safety, it's critical to understand the materials you rely on. The problem isn't the boot; it's the chemistry of the sole.

What is Polyurethane (PU)?

Polyurethane is a polymer commonly used for the midsole and outsole of high-quality work boots.

Manufacturers choose PU for its excellent properties: it's lightweight, flexible, and provides superior shock absorption and cushioning. This makes the boots comfortable for long days on your feet.

The Science of Hydrolysis

Hydrolysis is the chemical breakdown of a compound due to a reaction with water. In PU soles, moisture from the air—even humidity—attacks the long polymer chains that give the material its strength.

Think of these chains as a strong net. Water molecules act like tiny scissors, snipping the links in the net. Over months and years, enough links are cut that the entire structure becomes weak and falls apart.

Why Inactivity Accelerates the Problem

Paradoxically, not using your boots makes the problem worse. Storing them allows moisture to sit undisturbed within the PU's microscopic structure.

Regular walking and flexing helps to disperse this trapped moisture and keeps the polymer chains active. Stagnation allows the chemical degradation to proceed unchecked and often at a faster rate.

Recognizing the Signs of Sole Degradation

Hydrolysis can be subtle at first, but it inevitably leads to catastrophic failure. Knowing the signs can prevent you from relying on a boot that is about to fail.

Early Warning Signs

Before the sole crumbles, you might notice small, web-like cracks appearing on the surface of the midsole. The material may also begin to feel slightly sticky or tacky to the touch as the polymers break down.

Advanced Failure (Crumbling)

The most dramatic sign is when the sole disintegrates. It may crack into large chunks or crumble into a dust-like substance with minimal force. This often happens suddenly when you put the boots on after a long period of storage.

Understanding the Trade-offs of PU Soles

The choice to use Polyurethane in work boots is a deliberate engineering decision that involves balancing benefits and drawbacks.

The Benefit: Comfort and Performance

There is a reason PU is so common in premium footwear. Its combination of light weight and high-performance cushioning is difficult to match with other materials like rubber, which is heavier and often less flexible.

The Inherent Downside: A Limited Lifespan

The trade-off for this comfort is a finite "shelf life." Hydrolysis is an unavoidable aging process. A brand-new pair of boots with PU soles has a lifespan that starts from the day it was manufactured, not the day you buy it.

How to Maximize Your Boots' Lifespan

While you cannot stop hydrolysis, you can slow it down with proper care and strategic use.

- If your primary focus is short-term storage: Clean the boots thoroughly and ensure they are completely dry. Store them in a temperature-controlled, well-ventilated area away from direct sunlight.

- If your primary focus is rotating multiple pairs: This is the ideal scenario. Regular but not daily use allows each pair to fully dry out while still getting the beneficial flex that disperses moisture.

- If your primary focus is buying for future use: Avoid "stocking up." Check the manufacturing date on the box or boot tag and purchase the newest pair available to maximize its usable lifespan.

Understanding the material science of your gear is the first step to ensuring its reliability and longevity.

Summary Table:

| Issue | Cause | Result |

|---|---|---|

| Sole Disintegration | Hydrolysis (moisture reaction) | Brittle, crumbling PU soles |

| Accelerated by Storage | Lack of use traps moisture | Shortens boot lifespan |

| Warning Signs | Web-like cracks, sticky surface | Sudden failure risk |

Ensure your team's safety and comfort with reliable footwear from 3515. As a large-scale manufacturer, we produce a comprehensive range of durable work boots for distributors, brand owners, and bulk clients. Our expertise in material science helps mitigate issues like hydrolysis, delivering long-lasting performance. Contact us today to discuss your footwear needs and benefit from our extensive production capabilities.

Visual Guide

Related Products

- Premium Flame-Retardant Waterproof Safety Boots and Shoes

- Safety Footwear Wholesale Manufacturer for Custom OEM/ODM Production

- Custom OEM Training Shoes Wholesale Manufacturer Durable & Breathable

- Wholesale Safety Footwear Manufacturer for Bulk & Custom OEM Orders

- Advanced KPU Athletic Safety Shoe with Steel Toe Cap Anti-Slip Rotary Lacing System

People Also Ask

- What are work boots designed for? Ultimate Protection, Support & Durability

- Why is lightweight polyurethane (EVA) used for medical and work outsoles? Enhance Comfort & Safety in Every Step

- What changes occur in the leather after the wax treatment? A Guide to Enhanced Protection & Patina

- How can the right boot choice enhance work performance? Boost Safety, Comfort, and Endurance

- What are the differences between wedge outsoles and heeled outsoles in work boots? Choose the Right Traction for Your Job

- How do fire boots differ from standard tactical or work boots? Essential Safety Insights for High-Risk Environments

- What methods can improve the waterproofing of work boots? Boost Durability & Protection

- Why are PVC boots a good option for farm work? Unbeatable Chemical & Water Protection