The short answer is that regularly reviewing and updating your Personal Protective Equipment (PPE) program is critical because workplaces are not static. This process ensures your safety measures remain effective against new or previously unrecognized hazards, incorporate advancements in protective technology, and maintain regulatory compliance, ultimately preventing injuries and protecting your organization.

A PPE program should be treated as a living system, not a one-time checklist. Its value is not in its creation, but in its continuous adaptation to the changing realities of your work environment and technology.

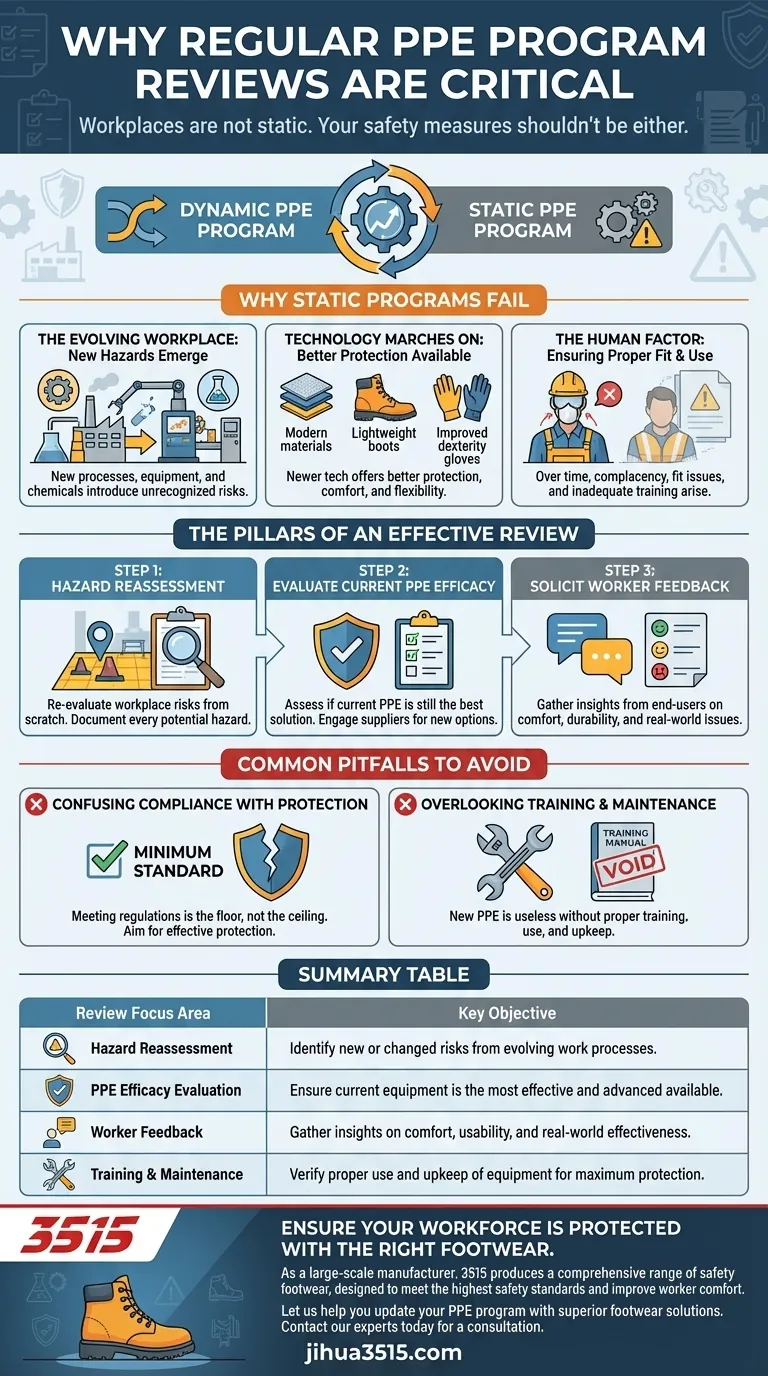

Why Static PPE Programs Fail

A "set it and forget it" approach to PPE is a direct path to increased risk. The initial hazard assessment and equipment selection are merely the starting point. Over time, a static program becomes misaligned with the actual risks your employees face.

The Evolving Workplace: New Hazards Emerge

Work processes change. New equipment is introduced, chemicals are substituted, and job roles are modified.

Each of these changes can introduce new hazards—or alter the nature of existing ones—that your original PPE selection was not designed to handle. A regular review proactively identifies these new gaps in protection.

Technology Marches On: Incorporating Better Protection

The technology behind PPE is constantly improving. New materials offer better protection with less weight, improved dexterity, or increased comfort.

For example, newer protective footwear might offer the same impact resistance with significantly more flexibility and breathability. An outdated program denies workers access to these superior solutions, which can improve both safety and employee morale.

The Human Factor: Ensuring Proper Fit and Use

A program is only effective if the PPE is used correctly. Over time, employees may become complacent, or new hires may be inadequately trained.

Regular reviews are an opportunity to re-evaluate not just the equipment itself, but also its fit, maintenance, and the quality of employee training associated with it.

The Pillars of an Effective PPE Program Review

A thorough review is a systematic process that goes beyond simply checking inventory. It involves a fresh look at the entire safety ecosystem.

Step 1: Conduct a Hazard Reassessment

Begin by re-evaluating the workplace as if you were seeing it for the first time. Walk the floor, observe tasks, and talk to the people doing the work.

Document every potential hazard, from the obvious (impact, chemical splash) to the less apparent (ergonomic strain, long-term exposure). Compare this new assessment to your existing one to immediately spot discrepancies.

Step 2: Evaluate Current PPE Efficacy

For each identified hazard, critically assess the currently issued PPE. Is it still the most appropriate and effective solution available?

Engage with suppliers to learn about new products and technologies that may offer superior protection or functionality. Don't assume last year's best option is still today's best option.

Step 3: Solicit Worker Feedback

Your employees are the end-users and a crucial source of information. They know what works, what doesn't, and what gets in the way of doing their job safely and efficiently.

Use surveys or direct conversations to ask about comfort, durability, and any difficulties they experience with their current PPE. This feedback is invaluable for driving user adoption and identifying unseen problems.

Common Pitfalls to Avoid

Simply going through the motions of a review is not enough. True success requires avoiding common traps that undermine the program's effectiveness.

Confusing Compliance with Protection

Meeting the minimum OSHA or other regulatory standard is the floor, not the ceiling. The primary goal is to protect your workers effectively, not just to check a compliance box.

A truly robust program often exceeds minimum requirements by selecting PPE that provides a higher margin of safety and usability.

Overlooking Training and Maintenance

Issuing new, state-of-the-art PPE is useless without comprehensive training on its proper use, limitations, and maintenance requirements.

An updated program must include an updated training and maintenance plan. Neglecting this step renders your investment in new equipment ineffective.

Making the Right Choice for Your Goal

Your review process should be guided by your organization's primary objectives.

- If your primary focus is risk mitigation: Prioritize the hazard reassessment to ensure you are addressing the most current and significant threats first.

- If your primary focus is operational efficiency: Look for new PPE technologies that enhance worker comfort and dexterity, potentially reducing task time and fatigue.

- If your primary focus is building a safety culture: Heavily weigh worker feedback in your selection process to demonstrate that their well-being is a top priority.

A proactive and regularly updated PPE program is one of the most reliable investments you can make in your people and your organization's resilience.

Summary Table:

| Review Focus Area | Key Objective |

|---|---|

| Hazard Reassessment | Identify new or changed risks from evolving work processes. |

| PPE Efficacy Evaluation | Ensure current equipment is the most effective and advanced available. |

| Worker Feedback | Gather insights on comfort, usability, and real-world effectiveness. |

| Training & Maintenance | Verify proper use and upkeep of equipment for maximum protection. |

Ensure your workforce is protected with the right footwear for every hazard.

As a large-scale manufacturer, 3515 produces a comprehensive range of safety footwear for distributors, brand owners, and bulk clients. Our production capabilities encompass all types of protective shoes and boots, from impact-resistant to chemical-proof, designed to meet the highest safety standards and improve worker comfort.

Let us help you update your PPE program with superior footwear solutions. Contact our experts today for a consultation on your specific needs.

Visual Guide

Related Products

- Premium Wholesale Wheat Nubuck Safety Boot with Rapid Lacing System

- Puncture-Resistant Velcro Safety Boots for Wholesale & Custom Manufacturing

- Safety Footwear Wholesale Manufacturer for Custom OEM/ODM Production

- Wholesale Safety Footwear Manufacturer for Bulk & Custom OEM Orders

- Customizable Anti-Smash Safety Boots for Wholesale & Private Label Manufacturing

People Also Ask

- What are the primary protective functions of safety shoes with steel toes in the automotive repair industry?

- What are the primary protective roles of safety shoes for mosquito control? Safeguard Workers from Chemical & Field Risks

- What role do industrial safety shoes with steel toes or composite protective layers play in high-risk manufacturing?

- What is the significance of providing standardized steel-toed safety shoes? Enhance Occupational Health Research Accuracy

- How do abrasion-resistant work boots extend equipment service life? Maximize Durability in Harsh Outdoor Environments