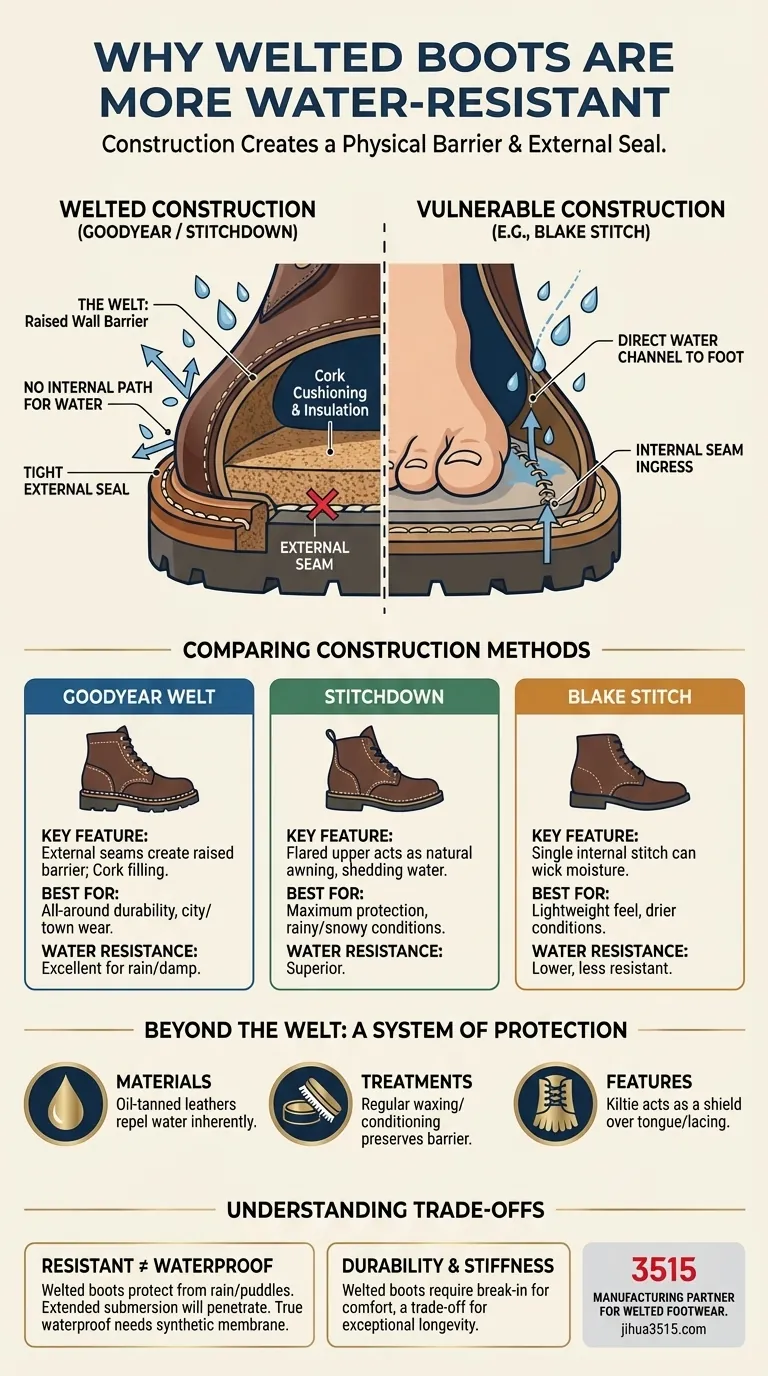

Welted boots are more water-resistant because their construction creates a physical barrier between the sole and the upper. Unlike other methods, the primary seams that hold the boot together are located on the outside, creating a tight seal and leaving no direct path for water to travel from the ground to your foot.

The superior water resistance of a welted boot comes from its fundamental structure, not just its materials. The welt acts as a raised wall, and the external stitching prevents water from having a direct channel to seep inside.

The Anatomy of a Welt: Your First Line of Defense

To understand the water resistance, you first need to understand the construction. A welted boot isn’t just glued together; it's meticulously engineered.

What is a Welt?

A welt is a strip of material, typically leather, that runs along the perimeter of the boot's outsole. It serves as the crucial connection point between the boot's upper (the part that covers your foot) and the sole.

Creating an External Seal

In a Goodyear welt construction, the upper is stitched to the welt, and then the welt is separately stitched to the outsole. This creates a small cavity between the insole and outsole, which is filled with cork for cushioning and insulation.

Think of it like the foundation of a house. The welt lifts the upper slightly away from the ground-level seam, making it much harder for water to climb up and in.

The Absence of Internal Seams

This external stitching is the key. Because the stitches connecting the sole do not penetrate directly through to the insole, you eliminate a common failure point for water entry.

Comparing Construction Methods for Water Resistance

The superiority of welting becomes clear when compared to other common methods of shoe construction.

The Goodyear Welt Advantage

As discussed, the external seams on a Goodyear welted boot provide excellent water resistance for everyday rain and damp conditions. It is the established benchmark for durable and weather-resistant footwear.

The Blake Stitch Vulnerability

In a Blake stitch construction, a single stitch runs directly from the outsole through the insole. While this makes the boot lighter and more flexible, it also creates dozens of small potential channels for moisture to wick its way up from a wet sole to your sock.

The Stitchdown Construction Edge

Considered by many to be even more water-resistant than a Goodyear welt, stitchdown construction involves flaring the boot's upper outward and stitching it directly to the midsole and outsole. This creates a natural awning that effectively sheds water away from the seam, making it exceptionally difficult for moisture to penetrate.

Beyond the Welt: A System of Protection

While the construction method is the foundation, it works in concert with other elements to keep your feet dry.

The Role of Materials

The type of leather used is critical. Oil-tanned leathers are impregnated with oils and waxes during the tanning process, making them inherently water-repellent. Materials like waxed canvas can also provide a high degree of resistance.

The Importance of Treatments

Even the most water-resistant boots require maintenance. Regularly applying wax or oil-based conditioners to leather boots replenishes their protective barrier and preserves the integrity of the material against moisture.

Often Overlooked Features

A feature like a kiltie—a fringed leather tongue cover—is not just decorative. It acts as an additional shield over the boot's tongue and lacing area, a common entry point for water.

Understanding the Trade-offs

It's crucial to have realistic expectations. "Water-resistant" is not the same as "waterproof."

Resistant vs. Waterproof

A welted leather boot is designed to protect you from rain, puddles, and snow. However, if submerged in water for an extended period, moisture will eventually seep through the leather and stitching. True waterproof performance requires a synthetic waterproof membrane.

The Point of Stitching Ingress

Over time and with heavy wear, the threads used in the welt stitching can absorb moisture or wear down. This is why stitchdown construction, which better protects the seams, can have an advantage in extremely wet conditions.

Durability Comes with Stiffness

Welted constructions, particularly Goodyear welts, are known for being stiffer out of the box. They require a break-in period to conform to your foot, which is a trade-off for their exceptional durability and longevity.

Making the Right Choice for Your Needs

Selecting the right boot depends entirely on its intended use and your environment.

- If your primary focus is all-around durability for city or town wear: A Goodyear welted boot offers the ideal balance of water resistance, longevity, and timeless style.

- If your primary focus is maximum protection in very rainy or snowy conditions: A boot with stitchdown construction made from oil-tanned leather will provide superior water resistance.

- If your primary focus is a lightweight, flexible feel for mostly dry conditions: A Blake-stitched boot is a suitable choice, but you must accept its lower resistance to water.

Understanding these construction principles empowers you to choose a boot that truly meets the demands of your environment.

Summary Table:

| Construction Method | Key Water-Resistance Feature | Best For |

|---|---|---|

| Goodyear Welt | External seams create a raised barrier; cavity filled with cork. | All-around durability, city/town wear. |

| Stitchdown | Flared upper acts as an awning, shedding water away from seams. | Maximum protection in rainy/snowy conditions. |

| Blake Stitch | Single internal stitch can wick moisture; less resistant. | Lightweight, flexible feel for drier conditions. |

Need durable, water-resistant boots for your customers?

As a large-scale manufacturer, 3515 produces a comprehensive range of welted footwear for distributors, brand owners, and bulk clients. Our expertise in constructions like Goodyear welt and stitchdown ensures your customers get superior protection and longevity.

Let's discuss your specific needs: Contact our team today to explore our production capabilities for all types of shoes and boots.

Visual Guide

Related Products

- Premium Wholesale Waterproof Safety Boots High Performance Protection for Industrial Markets

- High Performance Fire-Retardant Waterproof Safety Boots

- Premium High-Cut Waterproof Safety Boots Manufacturing & Wholesale Solutions

- Wholesale Waterproof Tactical Boots Custom Suede & High-Traction Soles

- Heavy-Duty Waterproof Nubuck Safety Boots Safety Shoes for Bulk Supply

People Also Ask

- What are the pros of Stitch-down Construction? Unmatched Durability & Support for Your Boots

- What type of boot construction is required by NFPA standards? Essential Laced Design for Wildland Firefighters

- What dual characteristics do industrial safety boots exhibit? Balance Worker Protection with Health Recovery Efficiency

- What are the cons of Stitch-down Construction? A Guide to Its Key Trade-offs

- What does the ASTM F2413-18 certification ensure for work boots? A Guide to Decoding Safety Ratings

- What are the differences between fire boots and regular work boots? A Guide to Life-Saving Footwear

- What features should construction and industrial work boots have? Essential Safety & Protection Guide

- What is Injection-Molded Construction in work boots? A Guide to Seamless Durability