Despite the rise of newer materials, steel toe boots remain a cornerstone of workplace safety for a simple reason: they offer an unparalleled combination of protection, durability, and cost-effectiveness. For a given thickness, steel provides superior resistance to impact and compression, often resulting in a protective cap with a slimmer profile than its composite counterparts.

The enduring prevalence of steel toe boots stems from a foundational principle: they provide the maximum level of impact and compression protection for their cost and physical volume, making them the most efficient choice for the highest-risk work environments.

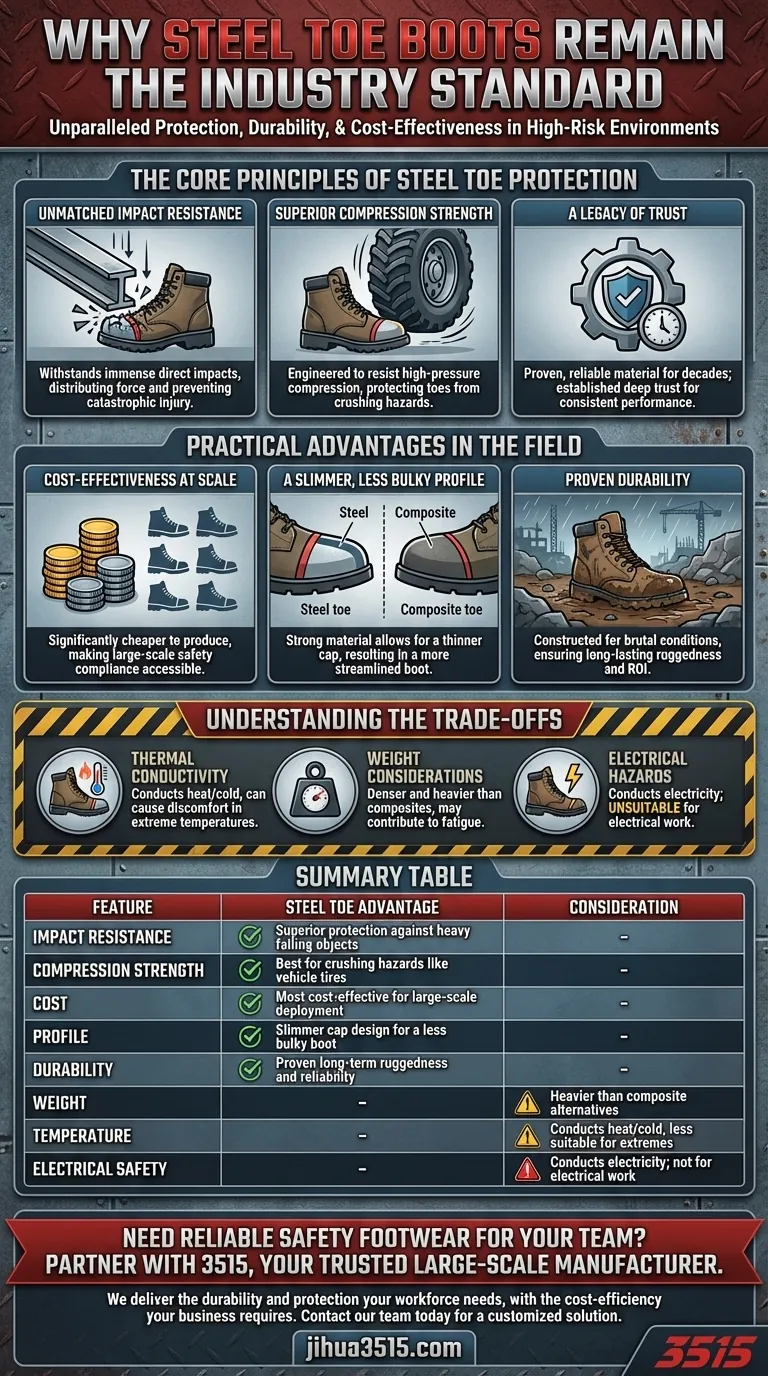

The Core Principles of Steel Toe Protection

To understand why steel persists, you must first understand the specific threats it is designed to neutralize. It has been the safety standard for decades in industries like construction and manufacturing for very specific reasons.

Unmatched Impact Resistance

The primary function of a safety toe is to protect the foot from falling objects. Steel's inherent strength and hardness allow it to withstand immense direct impacts, distributing the force and preventing catastrophic injury.

Superior Compression Strength

Beyond falling objects, workplaces often present crushing hazards, such as a vehicle tire rolling over a foot. Steel toe caps are engineered to resist high-pressure compression, maintaining their shape and protecting the toes from being crushed.

A Legacy of Trust

For decades, steel has been the proven, reliable material for foot protection. This long history has established a deep trust among safety managers and workers who depend on its consistent, predictable performance in hazardous situations.

The Practical Advantages in the Field

While its protective qualities are paramount, steel's widespread use is also driven by practical, real-world factors that matter to both individuals and the companies that employ them.

Cost-Effectiveness at Scale

Steel is significantly cheaper to produce than advanced composite materials. For companies outfitting entire workforces, this cost difference is a major factor, making compliance with safety standards more accessible.

A Slimmer, Less Bulky Profile

Because steel is so strong, the protective cap can be made relatively thin while still meeting or exceeding safety standards. This often results in a less bulky, more streamlined boot compared to a composite toe that may need more mass to achieve the same rating.

Proven Durability

Work boots are subjected to brutal conditions, from rough terrain to harsh weather. Steel toe boots are constructed for this reality, offering rugged durability that ensures they last for years, providing a reliable return on investment.

Understanding the Trade-offs

No single solution is perfect for every scenario. Being a trusted advisor means acknowledging the limitations of steel and recognizing where other materials may be a better choice.

Thermal Conductivity

Steel readily conducts temperature. In extremely cold environments, a steel toe can become very cold, and in hot environments, it can retain heat, leading to discomfort.

Weight Considerations

Steel is denser and heavier than composite materials like carbon fiber or Kevlar. For workers who walk many miles a day, the added weight can contribute to fatigue over a long shift.

Electrical Hazards

As a metal, steel conducts electricity. This makes traditional steel toe boots entirely unsuitable for electricians or anyone working in environments with a high risk of electrical shock.

Making the Right Choice for Your Role

The best safety boot is the one that correctly matches the specific hazards of your job. The choice between steel and other materials should be a deliberate one based on your daily tasks and environment.

- If your primary focus is maximum impact protection and cost: Steel toe remains the gold standard, especially for construction, heavy manufacturing, or material transport.

- If your primary focus is working in extreme temperatures or around live electrical circuits: A composite toe boot is the necessary and significantly safer choice.

- If your primary focus is reducing fatigue from constant walking or standing: Lighter composite toes may be a better option, provided they meet your job's required safety rating.

Ultimately, understanding the distinct advantages and limitations of steel allows you to make an informed decision that ensures your safety on the job.

Summary Table:

| Feature | Steel Toe Advantage | Consideration |

|---|---|---|

| Impact Resistance | Superior protection against heavy falling objects | - |

| Compression Strength | Best for crushing hazards like vehicle tires | - |

| Cost | Most cost-effective for large-scale deployment | - |

| Profile | Slimmer cap design for a less bulky boot | - |

| Durability | Proven long-term ruggedness and reliability | - |

| Weight | - | Heavier than composite alternatives |

| Temperature | - | Conducts heat/cold, less suitable for extremes |

| Electrical Safety | - | Conducts electricity; not for electrical work |

Need Reliable Safety Footwear for Your Team? Partner with 3515, Your Trusted Large-Scale Manufacturer.

As a leading manufacturer, 3515 produces a comprehensive range of high-performance steel toe and composite safety boots for distributors, brand owners, and bulk clients. We deliver the durability and protection your workforce needs, with the cost-efficiency your business requires.

Let's discuss your specific needs: Contact our team today to explore our catalog and get a customized solution for your safety footwear requirements.

Visual Guide

Related Products

- Premium Wholesale Waterproof Safety Boots High Performance Protection for Industrial Markets

- Premium Wholesale Wheat Nubuck Safety Boot with Rapid Lacing System

- Heavy Duty Nubuck Safety Boots Safety Shoes for Global Distribution

- Premium Sport Style Safety Boots for Bulk Orders

- Premium Grain Leather Safety Boots for Bulk Supply

People Also Ask

- Do steel toe boots increase the risk of trips and falls? How Quality Design Enhances Stability

- In what work situations might cowboy boots not be appropriate? A Guide to Safety & Dress Code Compliance

- What safety features can some gumboots have? Essential PPE for Hazardous Work Environments

- How do women's safety toe work boots protect against foot injuries? A Complete Guide to Workplace Foot Safety

- Is it true that steel toe boots make your toes colder? The Truth About Cold-Weather Work Boots