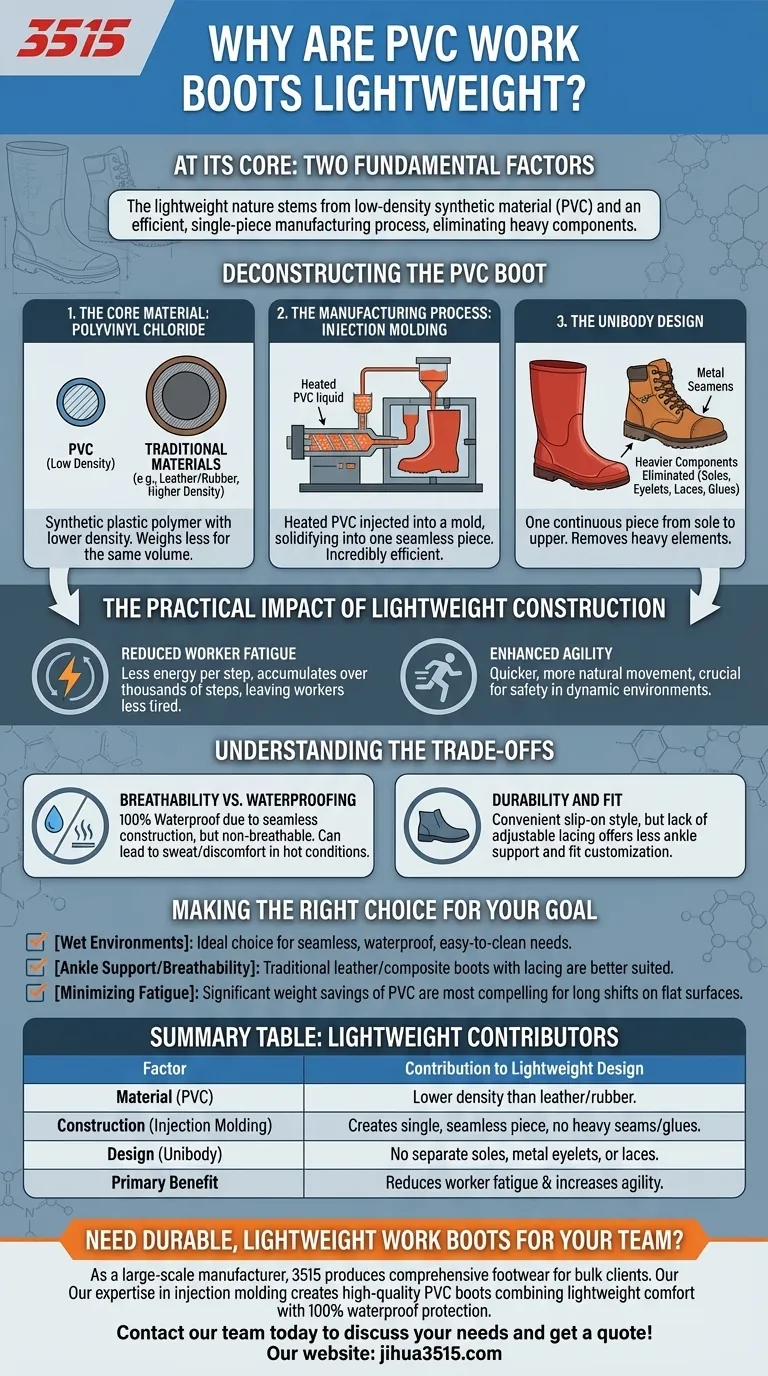

At its core, the lightweight nature of PVC work boots stems from two fundamental factors: the inherent low density of polyvinyl chloride (PVC) as a synthetic material and a highly efficient manufacturing process that creates a simple, single-piece design. This construction eliminates the heavier components found in traditional boots.

The key takeaway is that PVC boots are not just made from a light material; they are designed for lightness. Their injection-molded, unibody construction removes the need for heavier elements like leather, laces, multiple seams, and dense glues, resulting in a boot that is structurally simple and therefore exceptionally light.

Deconstructing the PVC Boot

To understand why PVC boots are so light, you must look at both the material they are made from and how they are assembled. These two aspects work together to minimize weight.

The Core Material: Polyvinyl Chloride

Polyvinyl chloride, or PVC, is a synthetic plastic polymer. By its very nature, it has a lower density compared to traditional footwear materials like thick leather or vulcanized rubber.

This means that for the same volume of material, PVC simply weighs less. This provides a significant head start in creating a lightweight final product.

The Manufacturing Process: Injection Molding

PVC boots are typically formed through injection molding. In this process, heated, liquid PVC is injected into a boot-shaped mold.

As it cools, it solidifies into a single, seamless piece. This method is incredibly efficient and is central to the boot's lightweight and waterproof characteristics.

The Unibody Design

The result of injection molding is a unibody construction. The entire boot, from the sole to the upper, is one continuous piece of PVC.

This design philosophy eliminates the need for separate, heavy components. There are no stitched-on soles, no metal eyelets, and no fabric laces, all of which add incremental weight to traditionally constructed boots.

The Practical Impact of Lightweight Construction

A boot's weight has a direct and significant impact on the person wearing it, especially over the course of a long workday.

Reduced Worker Fatigue

The primary benefit of a lightweight boot is a measurable reduction in fatigue. Every step requires less energy, and when you take thousands of steps per shift, this energy saving accumulates, leaving you less tired at the end of the day.

Enhanced Agility

Lighter footwear allows for quicker, more natural movement. This improved agility can be a crucial safety factor in environments where you need to move quickly or navigate obstacles.

Understanding the Trade-offs

While the lightweight design of PVC boots is a major advantage, it comes with inherent trade-offs that are important to consider.

Breathability vs. Waterproofing

The same seamless, molded construction that makes PVC boots 100% waterproof also makes them non-breathable. In hot conditions, this can lead to sweat and discomfort, as there is no way for moisture to escape.

Durability and Fit

The single-piece design, often lacking laces, offers a convenient slip-on style. However, this means the fit is not adjustable. For tasks requiring significant ankle support or on uneven terrain, the lack of a snug, laced fit can be a disadvantage.

Making the Right Choice for Your Goal

Selecting the correct boot means matching its inherent design advantages to the demands of your specific work environment.

- If your primary focus is working in wet environments: The seamless, waterproof, and easy-to-clean nature of a lightweight PVC boot is an ideal choice.

- If your primary focus is ankle support and breathability: A traditional leather or composite boot with a lacing system will likely serve you better, despite being heavier.

- If your primary focus is minimizing fatigue during long shifts on flat surfaces: The significant weight savings offered by PVC construction is its most compelling feature.

Ultimately, understanding a boot's material and construction allows you to choose the right tool for the job.

Summary Table:

| Factor | Contribution to Lightweight Design |

|---|---|

| Material (PVC) | Lower density than leather or rubber for the same volume. |

| Construction (Injection Molding) | Creates a single, seamless piece, eliminating heavy seams and glues. |

| Design (Unibody) | No separate soles, metal eyelets, or fabric laces to add weight. |

| Primary Benefit | Reduces worker fatigue and increases agility during long shifts. |

Need durable, lightweight work boots for your team?

As a large-scale manufacturer, 3515 produces a comprehensive range of footwear for distributors, brand owners, and bulk clients. Our expertise in injection molding allows us to create high-quality PVC boots that combine lightweight comfort with 100% waterproof protection, perfect for wet or demanding environments.

Let us help you equip your workforce with the right footwear. Contact our team today to discuss your needs and get a quote!

Visual Guide

Related Products

- High Performance Fire-Retardant Waterproof Safety Boots

- Premium High-Cut Waterproof Safety Boots Manufacturing & Wholesale Solutions

- Premium Wholesale Waterproof Safety Boots High Performance Protection for Industrial Markets

- Heavy-Duty Waterproof Nubuck Safety Boots Safety Shoes for Bulk Supply

- Premium Wholesale Wheat Nubuck Safety Boot with Rapid Lacing System

People Also Ask

- Are composite toe boots required by OSHA? Focus on the Right Protection for Your Team

- What are five style inspirations for wearing moc toe boots? Elevate Your Style with Timeless Versatility

- What type of footwear is currently being used for winter biking? Choose the Right Boots for Your Ride

- Are PVC boots used in outdoor work involving wet terrain? A Guide to Choosing the Right Work Boot

- How do work boot materials impact worker efficiency and safety? Match Materials to Your Work Environment

- What types of leather are commonly used in safety boots? Choose the Right Material for Maximum Protection

- Why are moc toe boots considered a versatile footwear choice? The Perfect Blend of Rugged Style & All-Day Comfort

- What are the functional purposes of the cowboy boot's design? Uncover the Engineering Behind the Icon