To put it simply, PVC boots are waterproof because they are made from a single, seamless piece of plastic called Polyvinyl Chloride (PVC). This material is inherently non-porous, meaning it has no holes for water to penetrate. Unlike leather or fabric, PVC does not absorb or hold moisture, ensuring your feet stay completely dry.

The core reason for PVC's waterproof nature isn't a special coating or treatment—it's the fundamental physical structure of the plastic itself. The real distinction lies in understanding how this simple barrier method differs from the more complex "breathable" waterproofing found in other types of boots.

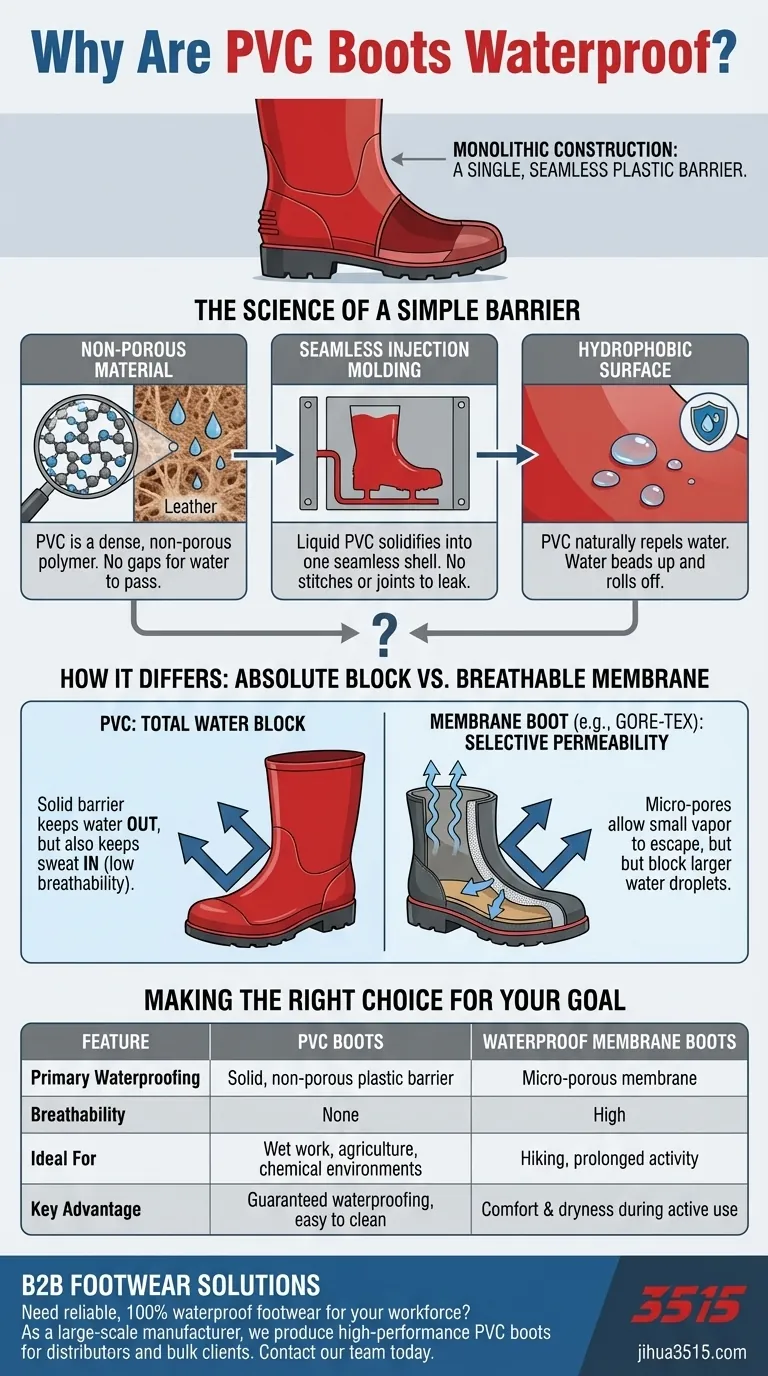

The Science of a Simple Barrier

The effectiveness of PVC boots comes from their monolithic construction. They function as a solid, impenetrable shield against liquids.

What is PVC?

Polyvinyl Chloride (PVC) is a synthetic plastic polymer. On a molecular level, its structure is dense and tightly bonded, leaving no gaps for water molecules to pass through.

The Power of Injection Molding

Most PVC boots are created using an injection molding process. Liquid PVC is injected into a single boot-shaped mold and solidifies. This process creates a seamless, one-piece shell with no stitches, seams, or joints where water could potentially leak.

Non-Porous by Nature

The surface of PVC is hydrophobic, meaning it repels water. It does not absorb moisture like natural materials such as leather or cotton. This is why water beads up and rolls right off a PVC boot.

How This Differs from Other "Waterproof" Boots

Understanding PVC's method of waterproofing becomes clearer when you compare it to the technology used in hiking or high-performance boots.

The "Waterproof, Breathable Membrane"

Modern walking and hiking boots often rely on a special lining, or "bootie," made from materials like GORE-TEX. This membrane contains billions of microscopic pores per square inch.

These pores are large enough to let small water vapor molecules (sweat) escape from inside the boot but are too small for larger liquid water droplets to get in from the outside.

The Role of Treated Materials

Boots made from materials like leather are not naturally waterproof. They rely on tannins, oils, or wax treatments to repel water. Over time, these treatments can wear off, and the material itself can eventually become saturated if submerged.

Understanding the Trade-offs

While PVC offers absolute waterproofing, its simplicity comes with distinct limitations compared to more advanced footwear.

The Breathability Issue

The primary drawback of PVC is its lack of breathability. Because it's a solid plastic barrier that keeps water out, it also keeps sweat and moisture in. In warm conditions or during strenuous activity, this can lead to damp, uncomfortable feet.

Limited Durability and Flexibility

PVC is a rigid material. It can become brittle and crack in very cold temperatures. It also offers less flexibility and support compared to materials like leather or the complex layers of a modern hiking boot.

The Advantage of Simplicity

For applications in industries like agriculture, food processing, or construction, PVC's simple, chemical-resistant, and easy-to-clean nature is a significant advantage. The guaranteed waterproofing far outweighs the need for breathability in these contexts.

Making the Right Choice for Your Goal

Selecting the right boot depends entirely on its intended use and the environment you'll be in.

- If your primary focus is absolute waterproofing for short-term, wet work: PVC boots are the most reliable and cost-effective choice.

- If your primary focus is keeping feet dry during prolonged activity like hiking: Boots with a waterproof, breathable membrane (like GORE-TEX) are essential to manage sweat and maintain comfort.

- If your primary focus is water resistance for daily wear in mixed conditions: Treated leather or fabric boots offer a good balance of protection, comfort, and style.

Ultimately, the right boot is the one that matches its waterproofing technology to the demands of your specific task.

Summary Table:

| Feature | PVC Boots | Waterproof Membrane Boots (e.g., GORE-TEX) |

|---|---|---|

| Primary Waterproofing | Solid, non-porous plastic barrier | Micro-porous membrane that blocks liquid water |

| Breathability | None | High (allows sweat vapor to escape) |

| Ideal For | Wet work, agriculture, chemical environments | Hiking, prolonged activity, all-weather comfort |

| Key Advantage | Guaranteed waterproofing, easy to clean, chemical-resistant | Comfort and dryness during active use |

Need reliable, 100% waterproof footwear for your business or workforce?

As a large-scale manufacturer, 3515 produces a comprehensive range of high-performance PVC boots and other footwear for distributors, brand owners, and bulk clients. Our injection molding expertise ensures seamless, durable, and completely waterproof boots perfect for demanding industries like agriculture, construction, and food processing.

We can help you:

- Source or customize durable PVC boots with guaranteed waterproof protection.

- Access a full range of footwear solutions for any application.

- Benefit from large-scale manufacturing efficiency and quality control.

Let's discuss your specific needs. Contact our team today to find the perfect footwear solution for your market.

Visual Guide

Related Products

- Wholesale Waterproof Tactical Boots Custom Suede & High-Traction Soles

- Premium High-Cut Waterproof Safety Boots Manufacturing & Wholesale Solutions

- High Performance Fire-Retardant Waterproof Safety Boots

- Factory Direct Wholesale Rain Boots Durable Waterproof & Fully Customizable

- Heavy-Duty Waterproof Nubuck Safety Boots Safety Shoes for Bulk Supply

People Also Ask

- What waterproof technology is used in tactical boots? Unlock All-Weather Performance & Protection

- What are tactical operations and what do they encompass? Master the Principles for Mission Success

- What was the primary motivation for developing this new jungle boot? Solving Critical Failures in Tropical Warfare

- Why is waterproofing important for tactical boots? Protect Your Feet and Gear in Any Mission

- Why is the thermal protection of tactical boots critical? Maintain Peak Performance in Extreme Cold and Wet Environments