At its core, protective toe boots are required on job sites to provide a final, critical line of defense against severe foot injuries. They are mandated in environments like construction, manufacturing, and logistics where feet are exposed to the constant risk of being crushed by falling objects or compressed by heavy equipment.

The requirement for protective toe boots isn't just about a single hazard; it's a comprehensive safety measure designed to mitigate a range of predictable, high-impact risks that could otherwise lead to permanent disability.

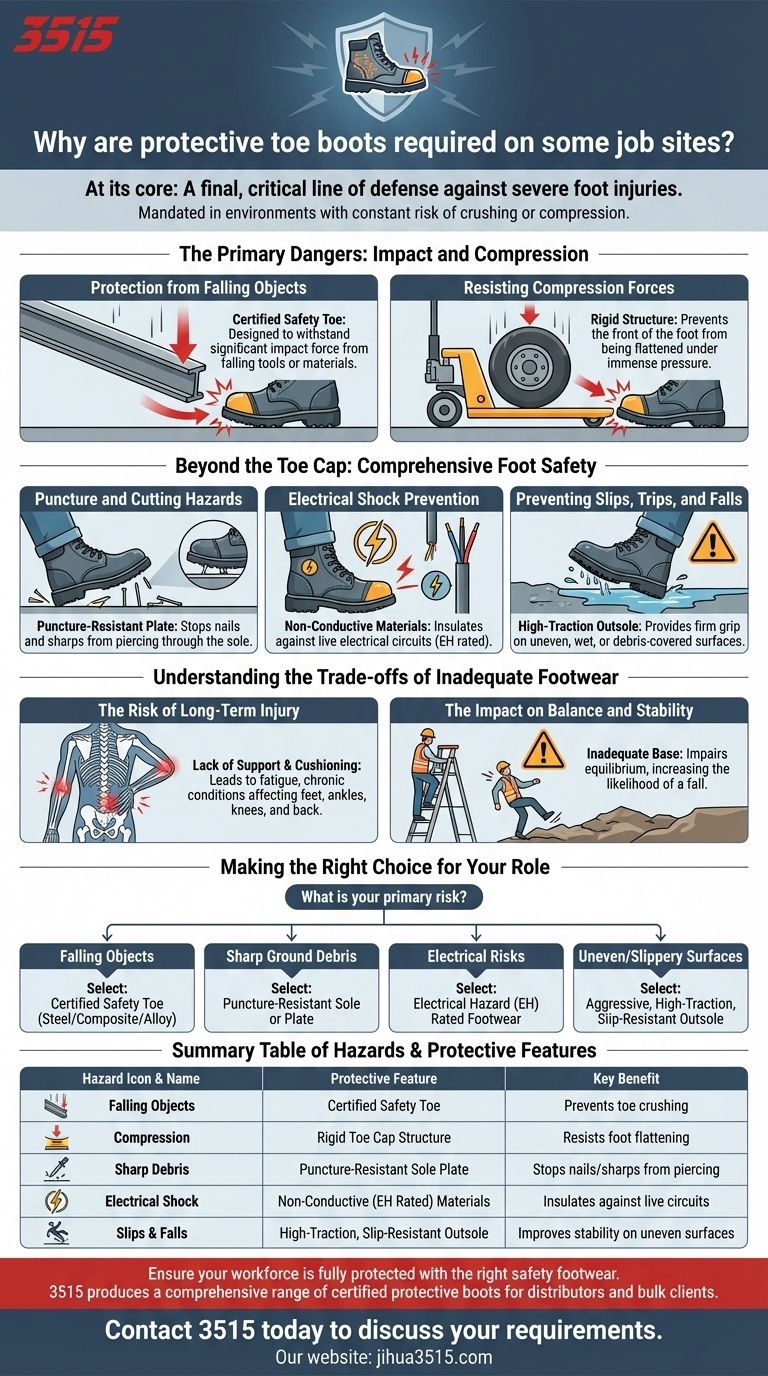

The Primary Dangers: Impact and Compression

The most obvious and severe threats on many job sites are from heavy objects. Protective toe boots are specifically engineered to counteract these two fundamental forces.

Protection from Falling Objects

In dynamic environments where materials and tools are constantly being moved, the risk of something being dropped is high. A certified safety toe is designed to withstand a significant impact force, protecting the toes from being crushed by falling tools, building materials, or other heavy items.

Resisting Compression Forces

This hazard involves the foot being squeezed or run over. A common scenario is a foot getting caught under a rolling cart, pallet jack, or the wheel of heavy machinery. The rigid structure of the protective toe cap prevents the front of the foot from being flattened under this immense pressure.

Beyond the Toe Cap: Comprehensive Foot Safety

While the toe cap is the most well-known feature, a true safety boot offers a multi-layered defense system against a variety of other common workplace hazards.

Puncture and Cutting Hazards

Job sites are often littered with sharp objects like nails, screws, and metal shards. Many safety boots include a puncture-resistant plate in the sole to prevent these items from piercing through the bottom of the foot. They also provide a tough barrier against cutting tools like chainsaws.

Electrical Shock Prevention

For electricians or maintenance workers, accidental contact with a live electrical circuit is a serious risk. Specialized safety footwear is built with non-conductive materials, such as rubber, to insulate the wearer and protect against dangerous electrical shocks.

Preventing Slips, Trips, and Falls

According to safety organizations, slips and falls are among the most common causes of workplace injuries. Protective boots feature high-traction outsoles with exceptional tread designed to provide a firm grip on uneven, wet, or debris-covered surfaces, significantly improving stability.

Understanding the Trade-offs of Inadequate Footwear

Choosing not to wear proper footwear, or choosing the wrong kind, introduces risks that go beyond a single catastrophic event. The consequences can be both immediate and cumulative.

The Risk of Long-Term Injury

Physically demanding jobs are like a daily marathon for your body. Footwear without proper support and cushioning contributes to fatigue and can lead to chronic conditions affecting the feet, ankles, knees, and back.

The Impact on Balance and Stability

The right footwear acts as a stable base for your entire body. Inadequate shoes can impair your equilibrium, making you less steady when climbing ladders, navigating rough terrain, or carrying heavy loads, which directly increases the likelihood of a fall.

Making the Right Choice for Your Role

Selecting the correct boot depends on a clear understanding of the specific risks you face every day.

- If your primary risk is falling objects: Your non-negotiable feature is a certified safety toe, whether it's made of steel, composite, or alloy.

- If you work around sharp ground debris: Prioritize a boot that explicitly features a puncture-resistant sole or plate.

- If you face electrical risks: Ensure your footwear has the proper Electrical Hazard (EH) rating to provide insulation.

- If you work on uneven or slippery surfaces: Look for boots with aggressive, high-traction, and slip-resistant outsoles.

Ultimately, wearing the required protective footwear is a foundational investment in your own safety and long-term well-being.

Summary Table:

| Hazard | Protective Feature | Key Benefit |

|---|---|---|

| Falling Objects | Certified Safety Toe (Steel/Composite) | Prevents toe crushing |

| Compression | Rigid Toe Cap Structure | Resists foot flattening |

| Sharp Debris | Puncture-Resistant Sole Plate | Stops nails/sharps from piercing |

| Electrical Shock | Non-Conductive (EH Rated) Materials | Insulates against live circuits |

| Slips & Falls | High-Traction, Slip-Resistant Outsole | Improves stability on uneven surfaces |

Ensure your workforce is fully protected with the right safety footwear. As a large-scale manufacturer, 3515 produces a comprehensive range of certified protective boots for distributors, brand owners, and bulk clients. Our production capabilities encompass all types of safety footwear, from steel-toe boots for construction to EH-rated boots for electricians. We can provide the durable, compliant footwear your team needs to mitigate workplace risks effectively.

Contact 3515 today to discuss your specific requirements and get a quote for your next order.

Visual Guide

Related Products

- Wholesale Customizable Safety Boots Durable & Protective Footwear Manufacturing

- Advanced KPU Athletic Safety Shoe with Steel Toe Cap Anti-Slip Rotary Lacing System

- Wholesale Premium Waterproof Nubuck Safety Shoes Boots

- Premium Suede Sport Safety Shoes for Wholesale & Bulk Orders

- Durable Leather Safety Boots for Wholesale & Custom OEM Manufacturing

People Also Ask

- What chemical protection features do safety shoes offer? A Guide to Hazard-Resistant Footwear

- What are the technical and construction advantages of professional-grade Safety Shoes? Enhance Stability and Grip

- What are the main types of safety-toe boots? Choose the Right Protection for Your Job

- What is the significance of integrating safety helmet detection with professional safety shoe management in projects?

- When is chainsaw protection (CS) required in safety footwear? Essential for Ground-Level Chainsaw Operation

- What is the importance of using standardized measurement tools in the quality assessment of safety footwear? Key Benefits

- What is the strategic market function of high-specification Safety Shoes for footwear distributors? Grow Your Portfolio

- How do ASTM F2412 and ASTM F2413 standards differ? A Guide to Safety Footwear Compliance