At its core, a certification is your only proof of protection. Work shoe certifications, such as the European standard EN ISO 20345, are official confirmations that a shoe has been independently tested and verified to meet specific safety requirements. They provide an objective guarantee that the footwear will protect you from documented hazards like heavy impacts, sole punctures, slips, and electrical shocks.

Work shoe certification moves safety from a vague marketing claim to a verified, measurable fact. It is the most reliable way to ensure your footwear has been rigorously tested to protect you against the specific, real-world hazards you face on the job.

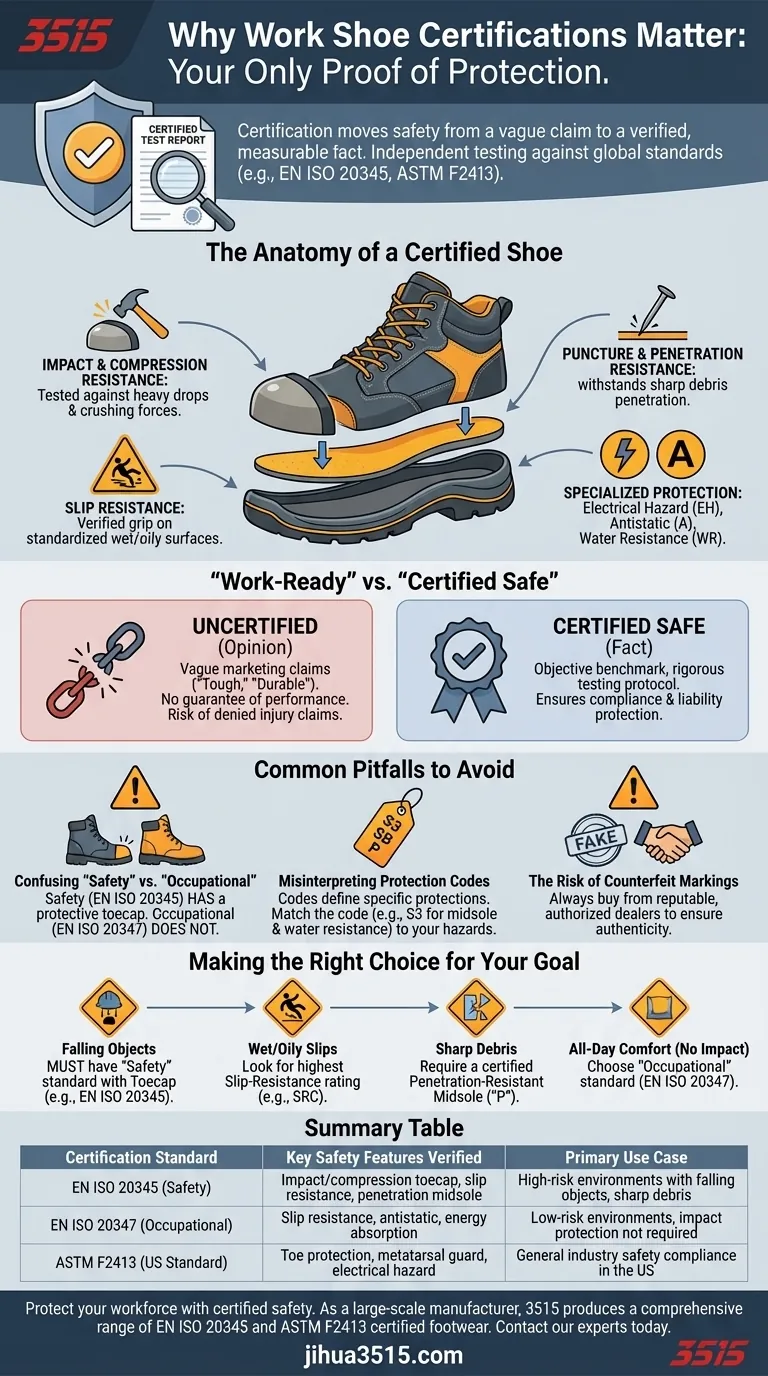

The Anatomy of a Certified Shoe

A certification isn't just a single pass/fail grade; it's a detailed report card on a shoe's performance against a battery of standardized tests. Understanding what is being tested helps you appreciate the protection you are getting.

Impact and Compression Resistance

This is the most fundamental feature of a true safety shoe. The protective toecap is tested by dropping a heavy weight (an "impactor") from a set height to measure its resistance to impact. It is also subjected to a heavy compressive force to ensure it won't crush under pressure.

Slip Resistance

Slips are one of the most common workplace accidents. Certified shoes are tested on standardized surfaces, such as a ceramic tile wetted with a soap solution or a steel floor with glycerol. This testing results in a specific slip-resistance rating, providing a reliable measure of the outsole's grip.

Puncture and Penetration Resistance

For environments with sharp debris like nails or scrap metal, this test is critical. A certified shoe with a penetration-resistant midsole must be able to withstand a specific force from a standardized sharp point without being pierced.

Specialized Hazard Protection

Beyond the basics, certifications can cover a wide range of specialized needs. This includes testing for electrical hazard (EH) resistance, antistatic properties (A) to prevent static buildup, and water resistance (WR) for wet working conditions.

"Work-Ready" vs. "Certified Safe"

The distinction between a shoe marketed as "tough" and one that is officially certified is the difference between an opinion and a fact. Without certification, you have no guarantee of performance.

The Problem with Uncertified Footwear

Terms like "durable," "heavy-duty," or "work-ready" are marketing claims, not safety specifications. An uncertified boot may look the part, but it has not been subjected to the controlled, repeatable tests required to prove its protective capabilities.

The Guarantee of a Standard

A certification mark (like EN ISO 20345 or the US equivalent, ASTM F2413) means the shoe passed a strict, defined testing protocol. It offers an objective benchmark for safety, allowing employers and workers to make informed decisions based on data, not advertising.

Legal and Insurance Implications

In many professional environments, using certified footwear is a non-negotiable requirement. It is often mandated by workplace safety regulations and is critical for insurance liability. An injury sustained while wearing uncertified footwear could lead to a denied claim.

Common Pitfalls to Avoid

Navigating certifications requires a clear understanding of the codes. Choosing the wrong type of shoe, even if it's certified, can leave you exposed to risk.

Confusing "Safety" vs. "Occupational" Footwear

This is a critical distinction. Safety footwear (EN ISO 20345) is certified to have a protective toecap. Occupational footwear (EN ISO 20347) is certified for features like slip resistance but does not include a protective toecap. It's designed for jobs where impact risk is not present.

Misinterpreting Protection Codes

The codes that follow a standard are not all-inclusive. For example, a shoe rated "SB" (Safety Basic) meets only the minimum toecap requirement. A shoe rated "S3" includes toecap protection, antistatic properties, a penetration-resistant midsole, and water resistance. You must match the code to your specific hazards.

The Risk of Counterfeit Markings

The integrity of a certification depends on its authenticity. To avoid footwear with fake or misleading safety markings, always purchase from reputable, authorized dealers who can verify the product's compliance and testing history.

Making the Right Choice for Your Goal

Your specific work environment is the ultimate guide to selecting the right certified shoe. Analyze your daily risks and match them to the corresponding protection standard.

- If your primary focus is protection from falling objects: You must have a shoe certified to a "Safety" standard that includes toecap impact resistance, like EN ISO 20345 or ASTM F2413.

- If your primary focus is preventing slips on wet or oily surfaces: Look for the highest slip-resistance rating (often marked SRC) on any certified safety or occupational shoe.

- If your primary focus is working around sharp debris: Your shoe must have a certified penetration-resistant midsole, often designated with a 'P' in its safety code.

- If your primary focus is all-day comfort without impact risk: A certified "Occupational" shoe (e.g., EN ISO 20347) can provide verified slip resistance and support without the weight of a safety toe.

Ultimately, choosing certified footwear means you are letting proven engineering, not marketing, protect you on the job.

Summary Table:

| Certification Standard | Key Safety Features Verified | Primary Use Case |

|---|---|---|

| EN ISO 20345 (Safety) | Impact/compression-resistant toecap, slip resistance, penetration-resistant midsole | High-risk environments with falling objects, sharp debris |

| EN ISO 20347 (Occupational) | Slip resistance, antistatic properties, energy absorption | Low-risk environments where impact protection is not required |

| ASTM F2413 (US Standard) | Toe protection, metatarsal guard, electrical hazard resistance | General industry safety compliance in the United States |

Protect your workforce with certified safety. As a large-scale manufacturer, 3515 produces a comprehensive range of EN ISO 20345 and ASTM F2413 certified footwear for distributors, brand owners, and bulk clients. Our production capabilities encompass all types of safety shoes and boots, rigorously tested to meet global standards. Ensure your team's safety and your company's compliance—contact our experts today to discuss your specific needs and receive a customized product catalog.

Visual Guide

Related Products

- Safety Footwear Wholesale Manufacturer for Custom OEM/ODM Production

- Premium Flame-Retardant Waterproof Safety Boots and Shoes

- Wholesale Safety Footwear Manufacturer for Bulk & Custom OEM Orders

- Premium Wholesale Tactical Style Safety Shoes Boots with Quick Lacing

- Wholesale Customizable Safety Boots Durable & Protective Footwear Manufacturing

People Also Ask

- How are boots designed to meet the ASTM protective toe standard? A Guide to Impact & Compression Safety

- How does defining specific friction interface models in FEA assist in predicting safety shoe toe cap failure modes?

- What materials are used in chemical-resistant safety boots? PVC, Rubber, or Neoprene?

- How does a rocker bottom mechanism improve footwear safety? Unlock superior durability and foot protection today.

- What are aluminum-toed shoes and how do they differ from steel-toed shoes? Choose the Right Safety Toe for Your Job

- What occupational hazards does industrial Safety Footwear address in high-risk environments? Essential Lab Safety Guide

- How do pressure and pulse sensors improve the automation efficiency of emergency alerts in smart safety footwear?

- Why are puncture-resistant soles considered indispensable for scaffolding? Essential Safety for High-Height Construction