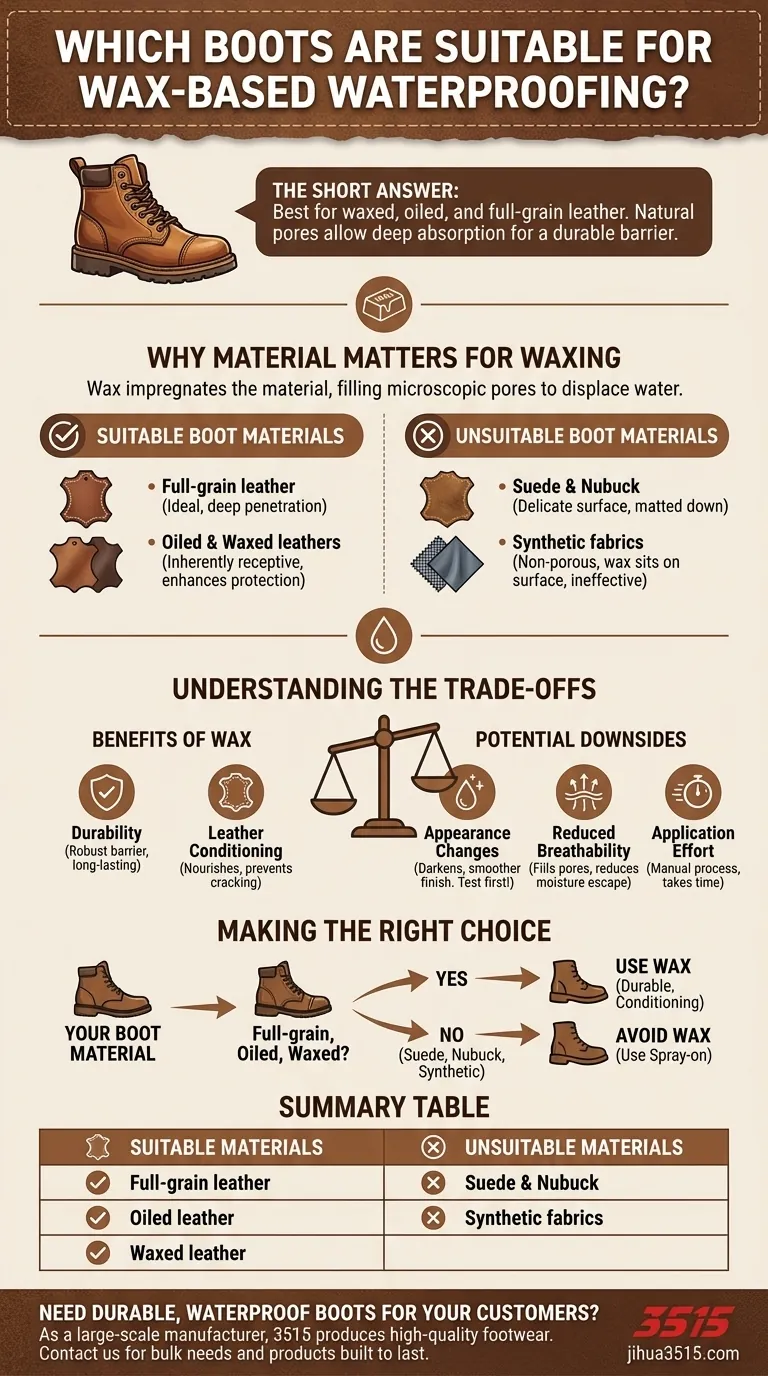

The short answer is that wax-based waterproofing is best suited for boots made of waxed, oiled, and full-grain leather. These types of leather have natural pores that allow the wax to be absorbed, creating a durable and effective water-resistant barrier from within the material itself.

Your boot's material dictates the best waterproofing method. While wax is a powerful, traditional choice, it's only truly effective on specific types of leather that can fully absorb it.

Why Material Matters for Waxing

When you apply wax to leather, you are not just coating the surface; you are impregnating the material. The goal is for the wax to fill the microscopic pores in the leather, displacing any water that might try to seep in.

Suitable Boot Materials

Full-grain leather is the ideal candidate for wax. It's the highest quality leather, made from the top layer of the hide, and it retains its natural grain and pores. This porous structure allows wax to penetrate deeply, providing excellent and long-lasting water resistance.

Oiled and waxed leathers are also excellent choices. These materials are already treated with oils and waxes during the tanning process, which makes them inherently more receptive to additional wax applications. Applying more wax simply replenishes and enhances this built-in protection.

Unsuitable Boot Materials

Applying wax to materials like suede, nubuck, or synthetic fabrics is generally not recommended. These materials either have a delicate surface (suede/nubuck) that will be matted down and ruined by heavy wax, or they are non-porous (synthetics) and the wax will simply sit on the surface, creating a greasy, ineffective mess.

Understanding the Trade-offs

Choosing wax for your boots comes with specific advantages and disadvantages. Understanding these will help you determine if it's the right method for your needs.

The Benefits of Wax

Durability is the primary advantage. A proper wax treatment creates a robust barrier that can withstand harsh conditions and lasts much longer than temporary spray-on treatments.

Leather Conditioning is another key benefit. Natural waxes, often made from beeswax, nourish the leather, keeping it supple and preventing it from drying out and cracking over time.

Potential Downsides

Appearance Changes are common. Applying wax will almost always darken the color of the leather. It can also slightly alter the texture, often giving it a smoother, shinier finish. Always perform a small patch test on an inconspicuous area first.

Reduced Breathability is a necessary compromise. Because wax fills the pores of the leather to keep water out, it also reduces the material's ability to let moisture (sweat) escape.

Application Effort is required. Unlike a quick spray, waxing boots is a manual process that involves warming, rubbing, and buffing the wax into the leather, paying close attention to seams and crevices.

Making the Right Choice for Your Boots

Your decision should be guided by your boot material and your performance expectations.

- If your boots are full-grain, oiled, or waxed leather: Wax is an excellent choice for durable, long-lasting water resistance and for conditioning the material.

- If your boots are suede, nubuck, or synthetic: Avoid wax and opt for a silicone or acrylic-based spray-on treatment designed specifically for those materials.

- If your primary focus is quick and easy application: A spray-on waterproofer is faster than wax, but you will need to reapply it much more frequently.

Ultimately, matching the waterproofing product to your boot's specific material is the most critical step in protecting your investment and keeping your feet dry.

Summary Table:

| Suitable Materials | Unsuitable Materials |

|---|---|

| Full-grain leather | Suede & Nubuck |

| Oiled leather | Synthetic fabrics |

| Waxed leather |

Need durable, waterproof boots for your customers? As a large-scale manufacturer, 3515 produces a comprehensive range of footwear for distributors, brand owners, and bulk clients. Our expertise in crafting high-quality full-grain and oiled leather boots ensures superior products ready for effective wax-based waterproofing. Contact us today to discuss your bulk footwear needs and enhance your product line with boots built to last.

Visual Guide

Related Products

- Durable Leather Tactical Boots Wholesale & Custom Manufacturing for Brands

- Durable Leather Work Boots Wholesale Manufacturer & Custom Factory

- Wholesale Waterproof Tactical Boots Custom Suede & High-Traction Soles

- Wholesale Durable Leather Work Boots | 8-Inch Goodyear Welt Manufacturer

- Durable Leather High-Ankle Tactical Boots for Wholesale & Custom Manufacturing

People Also Ask

- What temperature range does the user experience in their location during winter? (+5°C to -25°C)

- Why is an extra-wide toe box design essential in therapeutic shoes for Hallux Valgus? Key Benefits for Foot Health

- What are the resource efficiency benefits of centralized dry-cleaning? Maximizing Sustainability for Footwear and Apparel

- What role does Bluetooth connectivity and mobile applications play in smart vibratory insoles? Precision Digital Control

- What are the main types of men's boots and their primary purposes? A Guide to Work, Dress, Casual & Outdoor

- Why are standardized fabrics and linings leverage materials? Boost Footwear Margins Through Strategic Sourcing

- What is the purpose of specialized shielded goggles in gait experiments? Enhancing Data Purity in Visual Shift Studies

- Why is shoe color important for business casual outfits? Master Your Professional Style