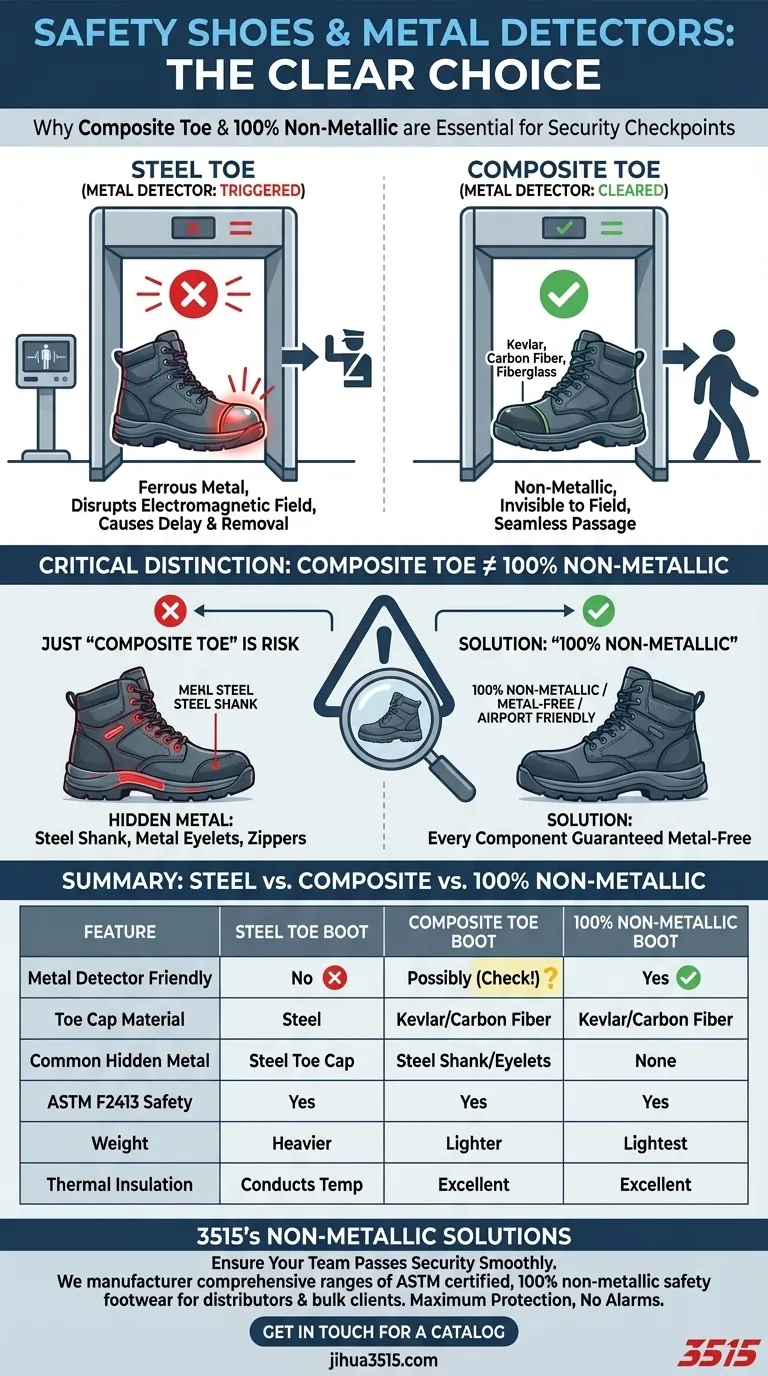

For passing through metal detectors, the correct choice is a safety shoe with a composite toe. Unlike traditional steel toes, composite materials like Kevlar, carbon fiber, and fiberglass are non-metallic and do not trigger security screening equipment. This allows workers to pass through checkpoints without the delay and inconvenience of removing their footwear.

The critical distinction is not just "composite toe vs. steel toe," but understanding that a shoe can have a non-metallic toe cap and still contain metal in other components. To ensure a shoe is checkpoint-friendly, you must select footwear that is explicitly certified as 100% non-metallic.

The Core Problem: Metal vs. Electromagnetism

To understand why this choice is so important, it's helpful to know how the technology interacts. The issue is not one of safety or protection, but of material science.

How Steel Toes Trigger Alarms

A steel toe cap is a significant piece of ferrous metal. Metal detectors function by creating an electromagnetic field and sensing disruptions within it. The large, conductive mass of a steel cap causes a major disruption, reliably triggering the alarm.

Why Composite Toes Go Unnoticed

Composite toe caps are made from non-conductive, non-magnetic materials. They are essentially "invisible" to a metal detector's electromagnetic field, allowing them to pass through without causing a disturbance or an alarm.

Beyond the Toe Cap: The "Metal-Free" Requirement

A common and costly mistake is assuming that any boot labeled "Composite Toe" is ready for a security checkpoint. The toe cap is only one part of the shoe's construction.

The Hidden Metal Components

Many safety boots, including some with composite toes, contain metal in other areas for structural purposes. The most common culprit is a steel shank, a supportive plate built into the midsole for arch support and puncture resistance. Other potential sources include metal eyelets for laces or small zippers.

Identifying a Truly Non-Metallic Boot

To avoid issues, you must look for specific classifications from the manufacturer. Look for labels such as "100% Non-Metallic," "Metal-Free," or "Airport Friendly." This certification guarantees that every component—from the toe cap and shank to the eyelets—is made from materials that will not trigger a metal detector.

Understanding the Trade-offs

Choosing a non-metallic boot does not mean compromising on safety. However, it's important to understand the different properties of the materials.

ASTM Safety Standards

Both composite and steel toe boots can be certified to the same ASTM F2413 standards for impact and compression resistance. A certified composite toe provides the same level of protection against falling objects and crushing forces as its steel counterpart.

Weight and Thermal Insulation

Composite materials are typically lighter than steel, which can reduce foot fatigue over a long shift. They also do not conduct temperature, offering superior insulation against both extreme heat and cold.

Durability and Profile

While both are exceptionally durable, steel can sometimes offer a slight edge against punctures from extremely sharp objects. Steel caps can also be made with a slightly thinner profile, though this is rarely a deciding factor.

Making the Right Choice for Your Goal

Selecting the correct footwear is a matter of matching the boot's specific features to your operational needs.

- If your primary focus is passing through security checkpoints without issue: You must select a boot explicitly labeled as "100% Non-Metallic" or "Metal-Free," not just "Composite Toe."

- If your primary focus is maximum safety in an environment without metal detectors: Both steel and composite toes that meet ASTM standards are excellent choices, and the decision can be based on other factors like weight or cost.

- If your primary focus is worker comfort in extreme temperatures: A composite toe is the superior choice because it does not conduct heat or cold, providing better insulation for the foot.

By understanding the distinction between a composite toe and a truly metal-free boot, you can ensure both seamless security passage and uncompromised worker safety.

Summary Table:

| Feature | Steel Toe Boot | Composite Toe Boot | 100% Non-Metallic Boot |

|---|---|---|---|

| Metal Detector Friendly | No | Possibly (Check for hidden metal) | Yes |

| Toe Cap Material | Steel | Kevlar, Carbon Fiber | Kevlar, Carbon Fiber |

| Common Hidden Metal | Steel Toe Cap | Steel Shank, Metal Eyelets | None |

| ASTM F2413 Safety Certified | Yes | Yes | Yes |

| Weight | Heavier | Lighter | Lightest |

| Thermal Insulation | Conducts Temperature | Excellent Insulation | Excellent Insulation |

Ensure Your Team Passes Security Smoothly with 3515's Non-Metallic Safety Footwear

As a large-scale manufacturer, 3515 produces a comprehensive range of 100% non-metallic safety footwear for distributors, brand owners, and bulk clients. Our metal-free boots are rigorously tested to meet ASTM safety standards, providing maximum protection without triggering metal detectors. We offer a full spectrum of styles to meet your specific operational needs.

Contact us today to discuss your requirements and request a catalog: Get in Touch

Visual Guide

Related Products

- Premium KPU Athletic Safety Shoes for Wholesale

- Durable Rubber-Soled Utility Shoes for Wholesale & Custom Brand Manufacturing

- Premium Flame-Retardant Waterproof Safety Boots and Shoes

- Wholesale Leather Safety Boots with Customizable Protective Toe

- Wholesale Durable Breathable Safety Boots Custom OEM Manufacturer

People Also Ask

- How does a universal pressing machine ensure the bonding quality of safety shoes? Achieve Superior Structural Fusion

- What are the long-term benefits of investing in high-quality safety footwear? Protect Your Health & Career

- How do athletic-style safety shoes balance flexibility and safety? Perfect Agility for Active Professionals

- Where can one purchase firefighter boots? Find Trusted Sources for NFPA-Certified Gear

- What do common markings on work shoes indicate? Your Guide to Decoding Safety Footwear

- What are the advantages of composite toe shoes? Achieve Superior Safety and Comfort

- Why is the Y-Balance Test used to evaluate the balance support capabilities of safety shoes? Enhance Worker Stability

- Why are industrial safety shoes necessary for mining machinery maintenance? Protect Feet from Crushing and Punctures