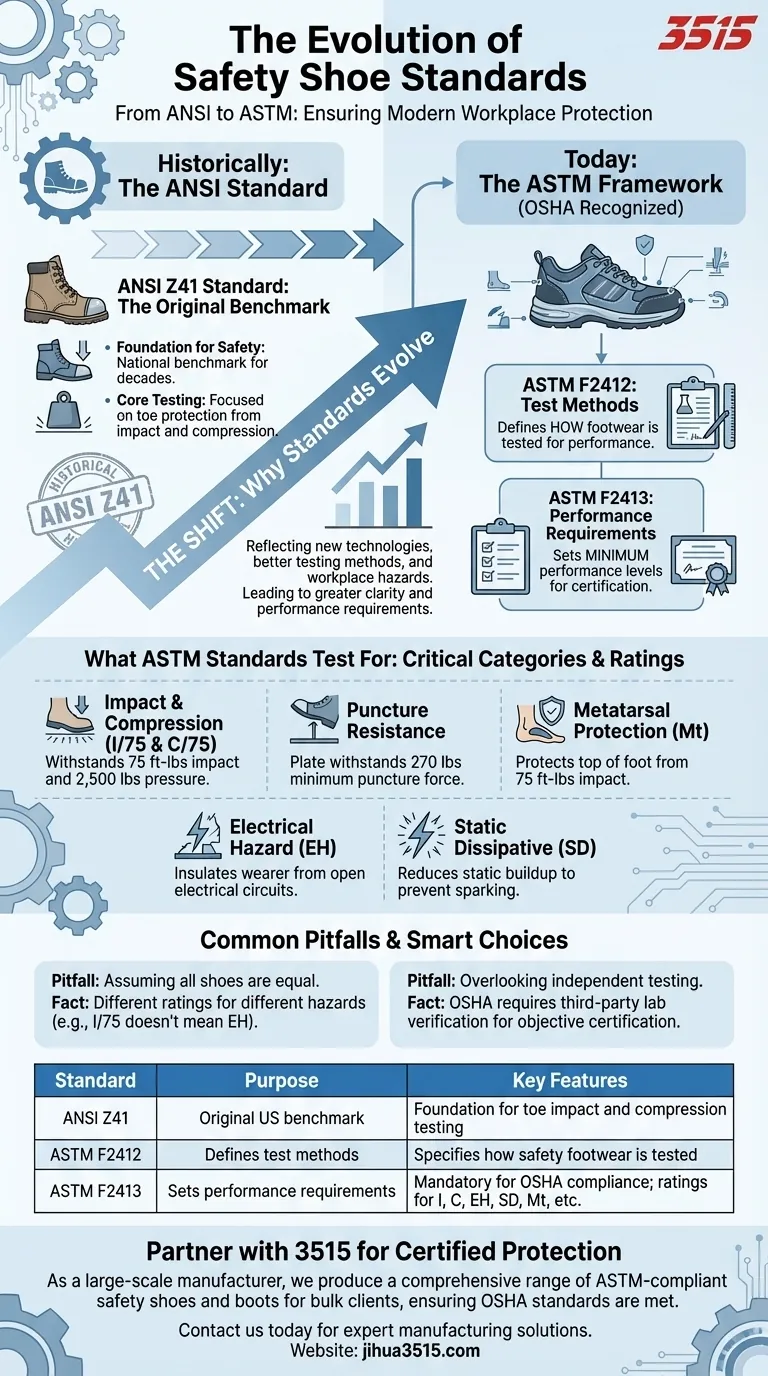

Historically, safety footwear was tested and certified under the standards set by the American National Standards Institute (ANSI). This served as the original benchmark for protective footwear in the United States for many years before the system evolved to the more specific standards used today.

The core evolution in safety shoe testing has been the transition from the foundational ANSI standards to the current, more detailed ASTM International standards (F2412 and F2413), which are now the required benchmark for OSHA compliance.

The Original Benchmark: The ANSI Standard

A Foundation for Safety

The ANSI Z41 standard was the original nationally recognized benchmark for safety-toe footwear. For decades, it provided the primary guidelines for testing the protective capabilities of work boots and shoes.

Core Testing Principles

Even under this older standard, the fundamental goals were the same as they are today. Testing focused primarily on a shoe's ability to protect the wearer's toes from both direct impacts and crushing compression forces.

The Shift to a New Standard: The Rise of ASTM

Why Standards Evolve

Safety standards are not static. They are monitored and updated to reflect new technologies, better testing methods, and a deeper understanding of workplace hazards. The transition from ANSI to ASTM represents this continuous effort to improve clarity and performance requirements.

The Current Governing Standards

Today, safety footwear is governed by two key standards from ASTM International (formerly the American Society for Testing and Materials).

- ASTM F2412: This standard outlines the Test Methods for Foot Protection. It defines exactly how safety footwear must be tested for performance.

- ASTM F2413: This standard specifies the Performance Requirements for Safety Toe Cap Footwear. It sets the minimum performance levels a shoe must meet during testing to be certified.

What Do These Standards Actually Test For?

Under the current ASTM framework, which is recognized by OSHA, certified footwear is evaluated by independent labs across several critical categories.

Impact and Compression Resistance

This is the most fundamental test for a "safety toe." The footwear is rated for its ability to withstand a force of up to 75 foot-pounds for impact (I/75) and 2,500 pounds of pressure for compression (C/75).

Puncture Resistance

For environments with sharp objects on the ground, footwear can be tested with a puncture-resistant plate in the sole. This plate must withstand a minimum puncture force of 270 pounds.

Metatarsal Protection

Standard safety toes only protect the front of the foot. Metatarsal guards (Mt) are designed to protect the delicate bones on top of the foot from impact forces of up to 75 foot-pounds.

Electrical Hazard (EH) and Static Dissipative (SD)

These ratings address electrical risks. EH-rated footwear is designed to insulate the wearer from open electrical circuits, while SD-rated footwear reduces the buildup of static electricity to prevent sparking in sensitive environments.

Common Pitfalls to Avoid

Assuming All Safety Shoes Are Equal

A common mistake is assuming any shoe with a steel toe offers complete protection. The ASTM standards provide specific ratings for specific hazards. A boot rated for impact (I/75) and compression (C/75) may offer no protection against electrical hazards unless it also carries an EH rating.

Overlooking the Need for Independent Testing

OSHA requires that safety footwear be tested at an independent, third-party laboratory. This ensures that the performance claims are objective and verifiable, providing a crucial layer of trust and reliability in the certification. Always verify that footwear has been properly certified to the current ASTM standard.

Making the Right Choice for Your Goal

- If your primary focus is historical context: Recognize that ANSI Z41 was the foundational standard, but all modern footwear is certified under the ASTM framework.

- If your primary focus is ensuring workplace compliance: Always look for footwear that is explicitly labeled as meeting ASTM F2413 performance requirements.

- If your primary focus is selecting for a specific hazard: Go beyond the basic safety toe and verify the shoe's specific ratings for impact (I), compression (C), electrical hazard (EH), or puncture resistance based on your job's unique risks.

Understanding this evolution from ANSI to ASTM empowers you to select safety footwear based on modern, comprehensive, and verifiable standards.

Summary Table:

| Standard | Purpose | Key Features |

|---|---|---|

| ANSI Z41 | Original US benchmark | Foundation for toe impact and compression testing |

| ASTM F2412 | Defines test methods | Specifies how safety footwear is tested |

| ASTM F2413 | Sets performance requirements | Mandatory for OSHA compliance; includes ratings for impact, compression, EH, SD, and more |

Ensure your workforce is protected with certified safety footwear from 3515. As a large-scale manufacturer, we produce a comprehensive range of ASTM-compliant safety shoes and boots for distributors, brand owners, and bulk clients. Our production capabilities cover all types of protective footwear, ensuring your team meets OSHA standards and stays safe on the job.

Contact us today to discuss your specific safety footwear needs and benefit from our expert manufacturing solutions.

Visual Guide

Related Products

- Safety Footwear Wholesale Manufacturer for Custom OEM/ODM Production

- Premium Wholesale Waterproof Safety Boots High Performance Protection for Industrial Markets

- Premium Sport Style Safety Boots for Bulk Orders

- Heavy Duty Nubuck Safety Boots Safety Shoes for Global Distribution

- Premium Wholesale Wheat Nubuck Safety Boot with Rapid Lacing System

People Also Ask

- What should you look for in motorcycle boots regarding abrasion resistance? Key Features for Maximum Slide Protection

- Why is it essential to have proper footwear in the workplace? Ensure Safety, Health, and Productivity

- What materials are used for fasteners and laces in safety boots? | A Guide to Durability & Safety

- How does Principal Component Analysis (PCA) contribute to the optimization of safety shoe and tactical boot design?

- What is the safety footwear standard in Australia? Ensure AS 2210.3:2019 Compliance

- What technical features are required in work shoes for manual collection on plantations? Essential Safety Standards

- What is a safety-toe in a boot? Your Guide to Choosing the Right Protection

- Why is it important to check the certification of safety boots? Ensure Legal Compliance & Worker Safety