When purchasing or verifying safety footwear, the current governing body for standards in the United States is the ASTM (American Society for Testing and Materials). This organization now manages the standards that were previously overseen by the ANSI (American National Standards Institute).

The core takeaway is that the official standard for safety footwear has transitioned from ANSI to ASTM. For modern compliance, you must look for the ASTM designation, as any reference to ANSI indicates an older manufacturing standard.

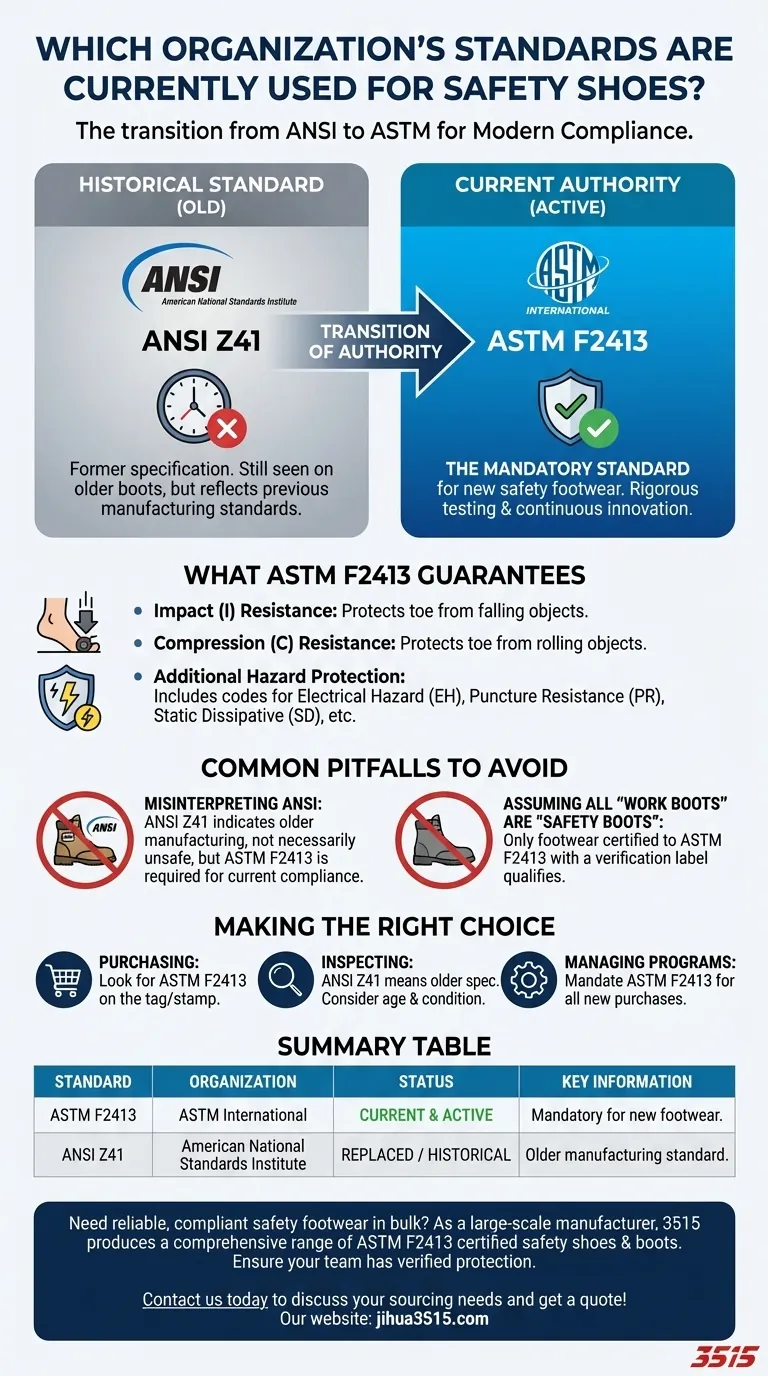

The Evolution of Safety Footwear Standards

To properly ensure compliance, it's important to understand not just the current standard, but also the one it replaced. This context helps you identify whether a shoe is up-to-date or manufactured under an older specification.

The Original Benchmark: ANSI

For many years, safety shoes were required to meet standards set by the American National Standards Institute (ANSI). The specific standard was known as ANSI Z41.

If you have older safety boots, you may still see a reference to this standard on the label.

The Current Authority: ASTM

The responsibility for setting these safety specifications was later transferred to ASTM International.

The current standard you must look for is ASTM F2413. This is the formal specification that outlines the minimum requirements for the design, performance, testing, and classification of protective footwear.

Why the Change Matters

This transition placed the standards under the authority of an organization that specializes in material and product testing.

While the core goal of protecting workers remains the same, the ASTM standards are subject to continuous review and innovation, with rigorous testing at every stage of development.

What the ASTM Standard Actually Guarantees

A shoe that meets the ASTM F2413 standard has been independently tested to protect you from specific workplace hazards. This isn't just a marketing claim; it's a verified certification.

Core Protection Ratings

The standard establishes minimum performance requirements for several critical categories:

- Impact (I) Resistance: Protects the toe area from falling objects.

- Compression (C) Resistance: Protects the toe area from rolling objects.

Additional Hazard Protection

The standard also includes specific codes for other protections, such as electrical hazard (EH), puncture resistance (PR), and static dissipative (SD) properties. A compliant shoe will have these specific ratings listed on its label.

Common Pitfalls to Avoid

Understanding the standards is only effective if you can apply that knowledge correctly. Many people make incorrect assumptions based on outdated information.

Misinterpreting an ANSI Label

Seeing an ANSI Z41 label does not mean a shoe is unsafe. It simply means it was manufactured and certified before the standard was updated and transferred to ASTM.

However, for any new purchase or for confirming current workplace compliance, the shoe must be rated for ASTM F2413. An older ANSI-rated shoe may be nearing the end of its effective lifespan.

Assuming All "Work Boots" are "Safety Boots"

A durable work boot is not necessarily a safety boot. Only footwear that has been tested and certified to meet the ASTM standard, with a label to prove it, qualifies as true safety footwear.

Making the Right Choice for Your Goal

Use the official standard as your definitive guide to ensure you are getting the protection you need.

- If your primary focus is purchasing new, compliant footwear: Look for a tag or stamp inside the shoe that explicitly states it meets ASTM F2413 standards.

- If your primary focus is inspecting existing footwear: Check the label. If it only references ANSI Z41, consider the shoe's age and condition, as it was made under an older specification.

- If your primary focus is managing a workplace safety program: Mandate that all new safety footwear purchases for your team must be certified to the current ASTM F2413 standard.

Verifying the correct standard is the most critical step in ensuring your safety on the job.

Summary Table:

| Standard | Organization | Status | Key Information |

|---|---|---|---|

| ASTM F2413 | ASTM International | Current & Active | The mandatory standard for new safety footwear. Look for this designation. |

| ANSI Z41 | American National Standards Institute | Replaced / Historical | Indicates older manufacturing standards. May not reflect current safety requirements. |

Need reliable, compliant safety footwear in bulk?

As a large-scale manufacturer, 3515 produces a comprehensive range of ASTM F2413 certified safety shoes and boots for distributors, brand owners, and bulk clients. We ensure every pair meets the latest safety standards, providing your team or customers with verified protection against impact, compression, and other workplace hazards.

Contact us today to discuss your sourcing needs and get a quote!

Visual Guide

Related Products

- Safety Footwear Wholesale Manufacturer for Custom OEM/ODM Production

- Custom Wholesale Leather Safety Boots Direct Factory Manufacturing

- Customizable Anti-Smash Safety Boots for Wholesale & Private Label Manufacturing

- Premium Wholesale Waterproof Safety Boots High Performance Protection for Industrial Markets

- Wholesale Safety Footwear Manufacturer for Bulk & Custom OEM Orders

People Also Ask

- What are the basic ratings of security guard safety boots? A Guide to EN ISO 20345 Standards

- What are the primary functions of industrial-grade safety shoes? Crucial Protection for Construction Safety

- What materials are commonly used in the manufacture of safety shoes? A Guide to Leather, Steel & Composite Components

- What industries commonly use composite toe work boots? Choose Lightweight, Non-Conductive Safety Footwear

- How can the monitoring of safety shoe usage be utilized as a KPI? Drive Compliance & Strategic Safety Management

- What does the ASTM F2892-18 certification confirm? A Guide to Soft Toe Protective Footwear

- Why might composite-toe boots be a better choice for passing through metal detectors? Ensure Security Checkpoint Efficiency

- What is the primary purpose of industrial-grade safety shoes? Protect Workers with Superior Hazard Defense