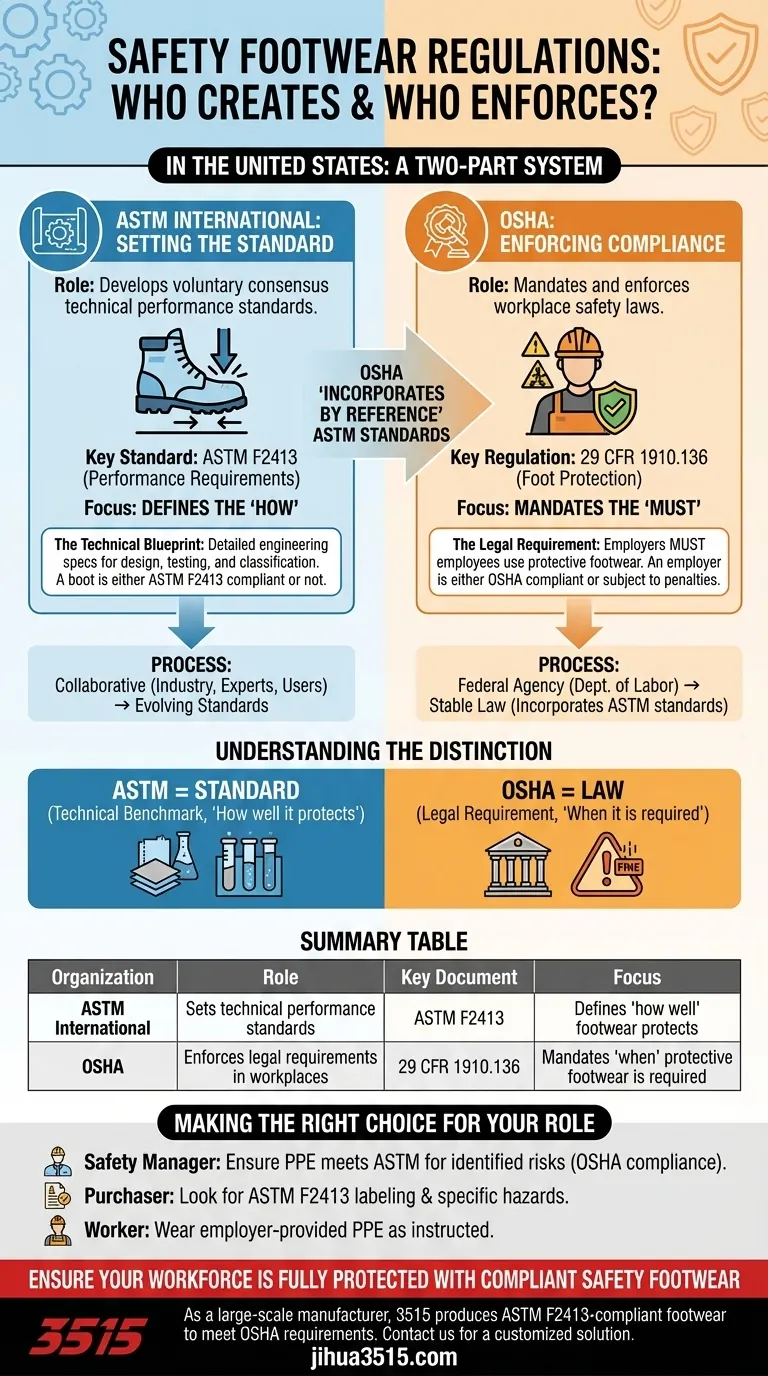

In the United States, safety footwear regulations are established by one organization and legally enforced by another. ASTM International is responsible for developing the technical performance standards for safety footwear, while the Occupational Safety and Health Administration (OSHA) is the government agency that mandates and enforces their use in the workplace.

The critical distinction to understand is that ASTM sets the technical benchmark for what makes a boot "safe," while OSHA makes wearing that benchmark-compliant footwear a legal requirement for employers in hazardous environments.

The Role of ASTM International: Setting the Standard

ASTM International is a globally recognized leader in the development and delivery of voluntary consensus standards. Their role is to define the specific performance requirements for protective equipment.

What is a Consensus Standard?

ASTM standards are not created by the government. Instead, they are developed through a collaborative process involving industry experts, manufacturers, academics, and end-users.

This consensus-based approach ensures the standards are practical, relevant, and based on the latest material science and testing methodologies.

The Key Footwear Standard: ASTM F2413

The primary standard for protective footwear is ASTM F2413: Standard Specification for Performance Requirements for Protective (Safety) Toe Cap Footwear.

This document outlines the minimum requirements for the design, performance, testing, and classification of safety footwear. It is the technical blueprint that manufacturers follow.

What ASTM F2413 Specifies

The standard details specific tests for various hazards. This includes minimum resistance criteria for impact and compression for the toe cap, as well as requirements for metatarsal protection, conductive properties, electrical hazard resistance, and puncture resistance.

The Role of OSHA: Enforcing Compliance

The Occupational Safety and Health Administration (OSHA) is a federal agency of the U.S. Department of Labor. Its mission is to ensure safe and healthful working conditions by setting and enforcing standards.

How OSHA Enforces the Rules

OSHA's regulation concerning foot protection is 29 CFR 1910.136. This rule legally requires employers to ensure that employees use protective footwear when working in areas with a danger of foot injuries.

These injuries can be due to falling or rolling objects, objects piercing the sole, or electrical hazards.

Leveraging ASTM's Expertise

Instead of creating its own complex technical footwear specifications, OSHA "incorporates by reference" the standards developed by organizations like ASTM.

This means OSHA's law states that required footwear must meet a specific ASTM standard. This allows the legal regulation to remain stable while the technical standard (ASTM F2413) can be updated more frequently by industry experts.

Understanding the Common Points of Confusion

The separation of duties between ASTM and OSHA is efficient but can cause confusion. Understanding the difference between a standard and a law is crucial for compliance.

ASTM Provides the "How"

Think of the ASTM standard as the detailed engineering specification. It answers the question, "How well must this boot protect the user against a specific hazard?"

A boot is either ASTM F2413 compliant or it is not. This is a technical statement of its performance capabilities.

OSHA Provides the "Must"

OSHA's regulation is the law. It answers the question, "In this specific work environment, must an employee wear protective footwear?"

An employer is either OSHA compliant or they are not. This is a legal statement about their workplace safety program. Failing an OSHA inspection can result in significant fines and legal penalties.

Why This Separation Matters

This system allows for a flexible and robust safety framework. ASTM can rapidly update technical standards as technology and materials evolve, while OSHA provides the unwavering legal authority to ensure those standards are actually used to protect workers on the job.

Making the Right Choice for Your Goal

Your responsibility depends on your role within your organization. Use these guidelines to ensure you are meeting the correct requirements.

- If you are a Safety Manager: Your primary concern is OSHA compliance. You achieve this by conducting a hazard assessment and ensuring the Personal Protective Equipment (PPE) you provide, including footwear, meets the relevant ASTM standard for the identified risks.

- If you are purchasing safety footwear: Your focus is on the ASTM standard. Look for labeling inside the boot that explicitly states it conforms to ASTM F2413 and specifies which hazards it protects against (e.g., I/75, C/75, EH, PR).

- If you are a Worker: Your responsibility is to wear the employer-provided PPE as instructed. Understand the markings on your boots to be aware of the specific protection they offer.

Ultimately, this two-part system ensures that the safety footwear you wear is both technically sound and legally required for your protection.

Summary Table:

| Organization | Role | Key Document | Focus |

|---|---|---|---|

| ASTM International | Sets technical performance standards | ASTM F2413 | Defines 'how well' footwear protects |

| OSHA | Enforces legal requirements in workplaces | 29 CFR 1910.136 | Mandates 'when' protective footwear is required |

Ensure Your Workforce is Fully Protected with Compliant Safety Footwear

As a large-scale manufacturer, 3515 produces a comprehensive range of ASTM F2413-compliant footwear for distributors, brand owners, and bulk clients. Our production capabilities encompass all types of safety shoes and boots designed to meet OSHA requirements.

We help you:

- Source technically sound footwear that meets ASTM standards

- Ensure full compliance with OSHA workplace regulations

- Protect your workforce with durable, reliable safety footwear

Contact us today to discuss your safety footwear needs and receive a customized solution from a trusted manufacturer.

Visual Guide

Related Products

- Safety Footwear Wholesale Manufacturer for Custom OEM/ODM Production

- Premium Flame-Retardant Waterproof Safety Boots and Shoes

- Advanced KPU Athletic Safety Shoe with Steel Toe Cap Anti-Slip Rotary Lacing System

- Wholesale Premium Waterproof Nubuck Safety Shoes Boots

- Premium Suede Metatarsal Guard Safety Boots Work Shoes

People Also Ask

- Are employers required to provide steel-toe rubber boots at no cost to employees? Yes, under OSHA rules.

- How do safety shoes contribute to cost savings for companies? A Strategic Investment in Risk and Cost Management

- What cultural and environmental considerations are tied to wearing shoes indoors? Balance Hygiene, Tradition, and Foot Health

- What materials are used for safety toes? Choose Steel, Composite, or Aluminum for Your Work Boots

- What are the primary protective functions of composite-toe boots? A Guide to Modern Safety Footwear