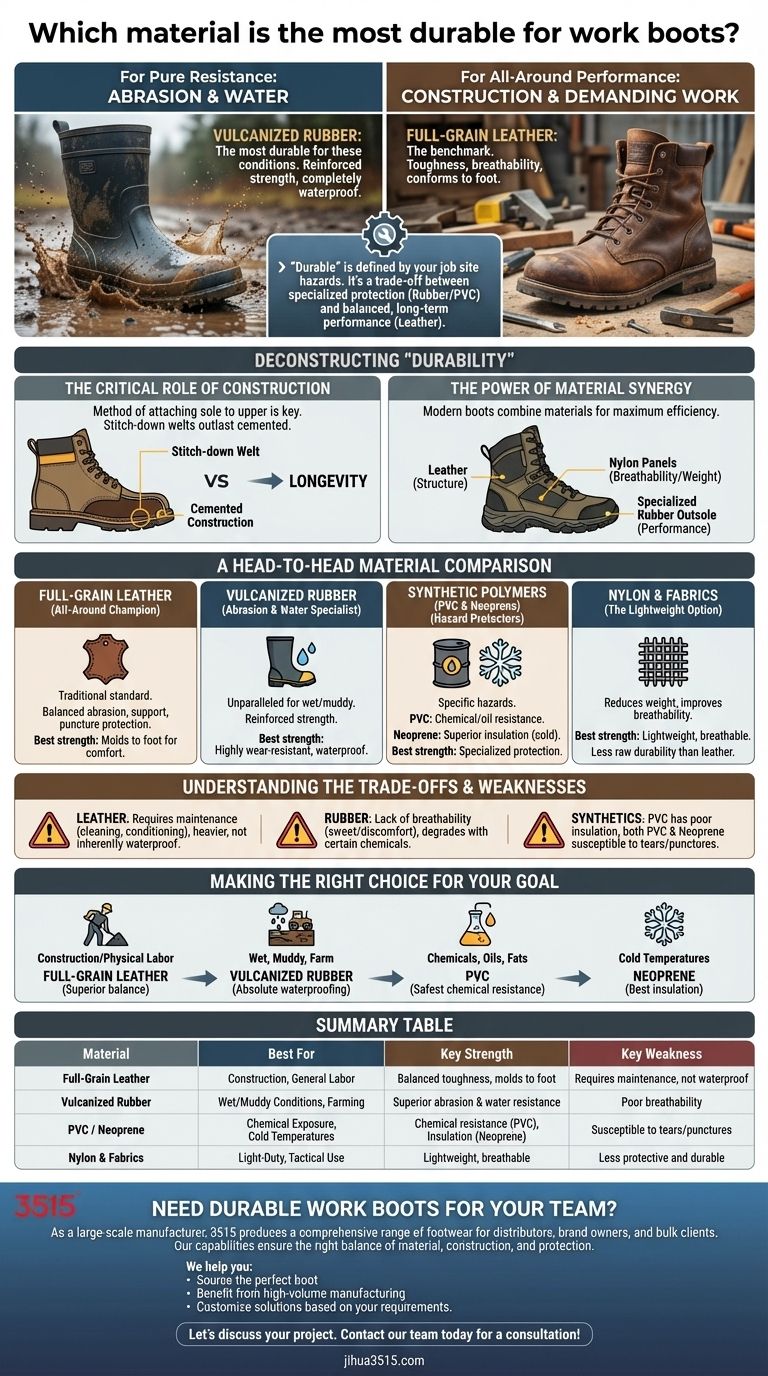

For pure resistance to abrasion and water, vulcanized rubber is the most durable material for work boots. However, for all-around performance in demanding work environments like construction, full-grain leather is the benchmark due to its unique combination of toughness, breathability, and ability to conform to your foot over time.

The most "durable" work boot material is not a single substance but is defined by your specific job site hazards. The choice is a trade-off between the specialized protection of rubber or PVC and the balanced, long-term performance of high-quality leather.

Deconstructing "Durability": More Than Just Material

True durability in a work boot comes from a combination of its material and its construction. A boot made from the toughest material will fail quickly if it's poorly assembled.

The Critical Role of Construction

The method used to attach the sole to the boot's upper is a primary indicator of longevity. Techniques like stitch-down welts create a robust, often repairable bond that significantly outlasts cheaper cemented construction.

The Power of Material Synergy

Modern high-performance boots, such as tactical models, rarely use a single material. They often combine leather for structure, nylon panels for breathability and reduced weight, and a specialized rubber compound for the outsole to maximize performance.

A Head-to-Head Material Comparison

Each material offers a distinct set of strengths tailored to different work environments. Understanding these differences is key to making the right choice.

Full-Grain Leather: The All-Around Champion

Leather is the traditional standard for high-quality work boots. It offers an excellent balance of abrasion resistance, support, and puncture protection. Its greatest advantage is its ability to mold to the shape of your foot, providing unmatched long-term comfort.

Vulcanized Rubber: The Abrasion & Water Specialist

For environments that are consistently wet, muddy, or involve significant surface wear, rubber is unparalleled. The vulcanization process reinforces its strength, making it highly resistant to wear and tear. It provides a completely waterproof barrier.

Synthetic Polymers (PVC & Neoprene): The Hazard Protectors

These materials are chosen for specific environmental hazards. PVC offers the best resistance to chemicals, oils, and animal fats, making it ideal for food processing or industrial cleaning. Neoprene provides superior insulation, trapping heat effectively in cold conditions.

Nylon & Fabrics: The Lightweight Option

Used to reduce weight and improve breathability, nylon is often found in tactical or lighter-duty boots. While tough, it does not offer the same level of raw durability and protection as a full-grain leather upper.

Understanding the Trade-offs

No single material is perfect for every situation. Being aware of the inherent weaknesses of each material is crucial for selecting a boot that won't fail you.

Leather's Weakness

High-quality leather requires maintenance, such as cleaning and conditioning, to prevent it from drying out and cracking. It is also heavier than synthetic options and is not inherently waterproof without a separate membrane liner.

Rubber's Downside

The primary drawback of rubber is its lack of breathability. This can lead to significant sweat and discomfort during long workdays. While tough against abrasion, it can degrade when exposed to certain oils and chemicals.

Synthetics' Limitations

PVC provides very little insulation, making it unsuitable for cold weather work. Both PVC and neoprene are more susceptible to tears and punctures than leather or high-quality rubber, making them less ideal for rugged, physically demanding environments.

Making the Right Choice for Your Goal

Your work environment is the ultimate guide. Select the material that directly counters the primary challenges and hazards you face every day.

- If your primary focus is construction or demanding physical labor: Choose full-grain leather for its superior balance of protection, support, and long-term comfort.

- If your primary focus is wet, muddy, or farm conditions: Select vulcanized rubber for its absolute waterproofing and high resistance to abrasion.

- If your primary focus is exposure to chemicals, oils, or fats: PVC is the safest choice, offering the most reliable chemical resistance.

- If your primary focus is working in cold temperatures: Look for neoprene boots to get the best insulation and keep your feet warm.

Choosing the right work boot means matching the material's strengths directly to the demands of your job.

Summary Table:

| Material | Best For | Key Strength | Key Weakness |

|---|---|---|---|

| Full-Grain Leather | Construction, General Labor | Balanced toughness, molds to foot | Requires maintenance, not waterproof |

| Vulcanized Rubber | Wet/Muddy Conditions, Farming | Superior abrasion & water resistance | Poor breathability |

| PVC / Neoprene | Chemical Exposure, Cold Temperatures | Chemical resistance (PVC), Insulation (Neoprene) | Susceptible to tears/punctures |

| Nylon & Fabrics | Light-Duty, Tactical Use | Lightweight, breathable | Less protective and durable |

Need Durable Work Boots for Your Team?

As a large-scale manufacturer, 3515 produces a comprehensive range of durable footwear for distributors, brand owners, and bulk clients. Our production capabilities encompass all types of work boots and shoes, ensuring you get the right balance of material, construction, and protection for your specific needs.

We help you:

- Source the perfect boot for any work environment, from construction sites to chemical plants.

- Benefit from high-volume manufacturing with consistent quality and competitive pricing.

- Customize solutions based on your unique requirements and branding.

Let's discuss your project. Contact our team today for a consultation!

Visual Guide

Related Products

- Durable Goodyear Welt Leather Work Boots for Wholesale & Private Label

- Durable Leather Work Boots for Wholesale & Custom Manufacturing

- Durable Leather Work Boots for Wholesale & Custom OEM Manufacturing

- Wholesale Durable Safety Boots Manufacturer Customizable Steel Toe Work Boots

- Customizable Anti-Smash Safety Boots for Wholesale & Private Label Manufacturing

People Also Ask

- What materials are used in Chemical Resistant boots for additional protection? Choose the Right Defense for Your Workplace

- How should work boots with zips be cared for? Extend Boot Life with Proper Zip Maintenance

- What are the differences between Lace Up, Zip Sided, and Pull On work boots? Find Your Perfect Fit for Safety & Convenience

- Why is high-quality leather a common material for firefighter boots? Unmatched Protection & Durability

- Can motorcycle boots be worn for everyday use? Finding the Perfect Balance for Daily Wear

- What are the benefits of composite toe boots? Achieve Lighter, Safer Foot Protection

- Why are work boots considered essential PPE? Unlock Superior Foot Protection for Your Workforce

- What factors should be considered when choosing cowboy boots for work? Find the Perfect Fit for Safety & Comfort