For harsh and demanding conditions, the best material for your work boots depends entirely on the specific nature of the hazard you face. For exceptional durability against physical wear and tear, rubber is the top recommendation. However, if your primary challenge is a cold and wet environment, neoprene offers superior insulation and flexibility to keep your feet warm and comfortable.

The central decision is a trade-off between physical durability and environmental protection. While no single material excels at everything, understanding whether your main challenge is abrasion or temperature is the key to selecting the right boot.

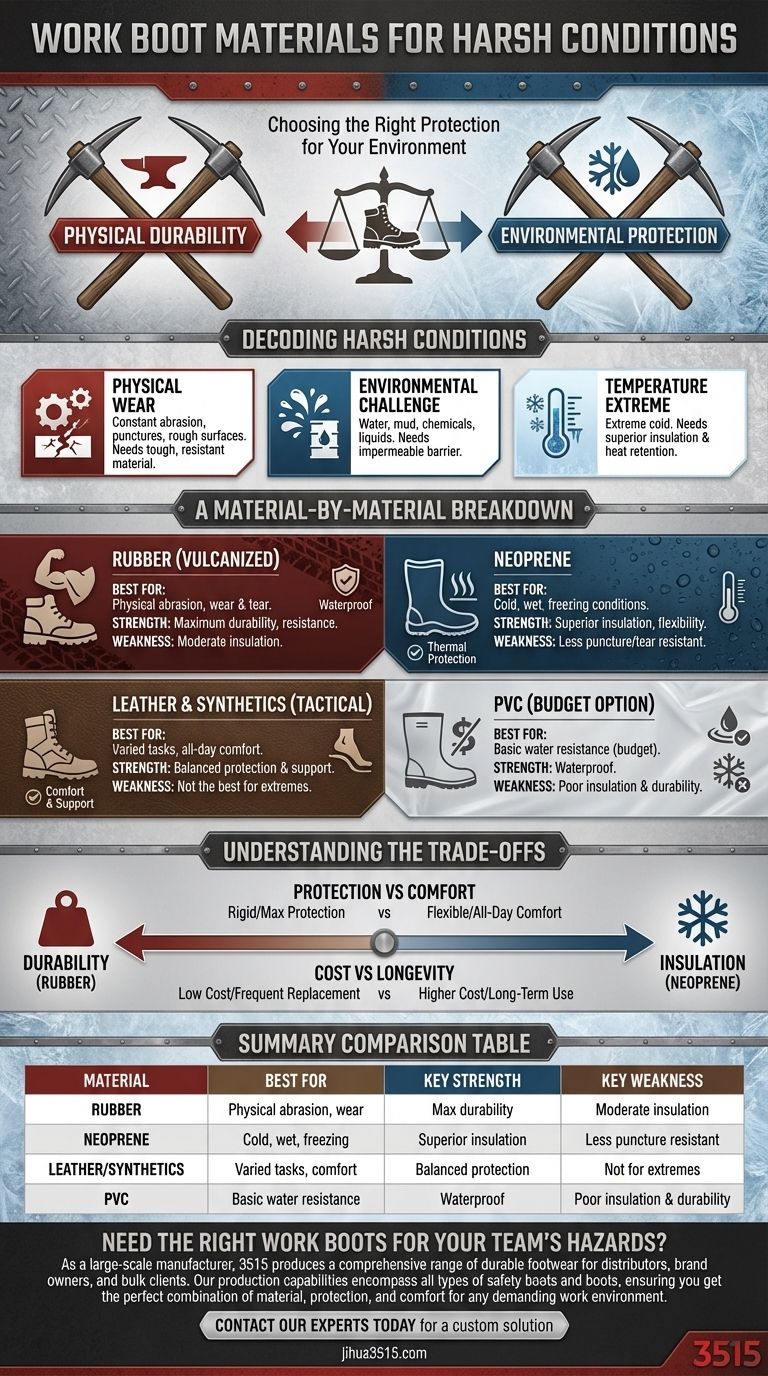

Decoding "Harsh Conditions"

The term "harsh" can mean many things in a work environment. To choose the right boot, you first need to identify the primary stress it will endure.

The Challenge of Physical Wear

This includes environments with constant abrasion, risk of punctures, and general wear and tear from rough surfaces. The material must be tough and resistant to being physically broken down.

The Challenge of Environment

This category covers exposure to water, mud, chemicals, and other liquids. The boot's primary job here is to create an impermeable barrier to keep your feet dry and safe.

The Challenge of Temperature

Extreme cold is a significant hazard. In these conditions, a boot's ability to insulate and retain body heat is the most critical performance factor, directly impacting safety and comfort.

A Material-by-Material Breakdown

Each common boot material has a distinct profile of strengths and weaknesses. The right choice is the one whose strengths align with your specific work environment.

Rubber: The Standard for Durability

Rubber, especially vulcanized rubber, is the most durable material for work boots. It offers exceptional resistance to wear and tear, making it ideal for physically demanding jobs.

While it provides a waterproof seal, its insulation properties are moderate. It offers some protection from the cold but is less effective than specialized materials.

Neoprene: The Insulation Champion

Neoprene is the best choice for cold and wet environments. Its structure excels at trapping warmth, and it conforms closely to your feet and legs, preventing heat from escaping.

It is highly flexible and comfortable, but it is more prone to tears and punctures than heavy-duty rubber. Its strength lies in thermal protection, not brute force resistance.

Leather and Synthetics: The Balanced All-Rounders

Modern military and tactical boots often use treated leather or advanced synthetic fabrics. These are designed for a balance of toughness, support, and long-term comfort.

Features like built-in arch support, water-resistant finishes, and sweat-absorbent insoles make them excellent for varied conditions where all-day wearability is as important as protection.

PVC: The Budget-Friendly Option

Polyvinyl chloride (PVC) is another waterproof option, but it is generally considered less robust. It is more susceptible to damage than rubber or neoprene.

Crucially, PVC provides minimal insulation, making it unsuitable for work in cold or freezing conditions.

Understanding the Trade-offs

Selecting the perfect work boot material is an exercise in balancing competing priorities. No single material can offer maximum performance in every category.

Durability vs. Insulation

This is the core trade-off. Rubber prioritizes physical toughness at the expense of top-tier insulation. Neoprene prioritizes warmth and flexibility, making it less resistant to severe physical abrasion.

Protection vs. Comfort

Heavily reinforced boots, like those designed for motocross or extreme off-road use, offer maximum protection. However, this level of rigidity often comes at the cost of flexibility and all-day comfort for walking or standing.

Cost vs. Longevity

Less expensive materials like PVC can provide basic water resistance, but they typically lack the durability and specialized features of rubber, neoprene, or high-quality tactical boots, leading to more frequent replacement.

Making the Right Choice for Your Work

Your specific goal determines the ideal material. Before you buy, clearly define the single greatest challenge your feet will face on the job.

- If your primary focus is durability against abrasion, chemicals, and physical wear: Choose a boot made from high-quality, vulcanized rubber.

- If your primary focus is warmth and comfort in cold, wet, or freezing conditions: Neoprene is the superior material for insulation and flexibility.

- If your primary focus is a balance of all-around protection, support, and all-day comfort for varied tasks: A high-quality pair of leather or synthetic military-style tactical boots is your best choice.

Ultimately, aligning the material's inherent strengths with your daily work hazards is the most effective way to ensure safety and comfort.

Summary Table:

| Material | Best For | Key Strength | Key Weakness |

|---|---|---|---|

| Rubber | Physical abrasion, wear & tear | Maximum durability | Moderate insulation |

| Neoprene | Cold, wet, freezing conditions | Superior insulation & flexibility | Less puncture/tear resistant |

| Leather/Synthetics | Varied tasks, all-day comfort | Balanced protection & support | Not the best in extreme conditions |

| PVC | Basic water resistance (budget) | Waterproof | Poor insulation & durability |

Need the right work boots for your team's specific hazards?

As a large-scale manufacturer, 3515 produces a comprehensive range of durable footwear for distributors, brand owners, and bulk clients. Our production capabilities encompass all types of safety boots and boots, ensuring you get the perfect combination of material, protection, and comfort for any demanding work environment.

Contact our experts today for a custom solution that meets your precise needs.

Visual Guide

Related Products

- Wholesale Durable Breathable Safety Boots Custom OEM Manufacturer

- Safety Footwear Wholesale Manufacturer for Custom OEM/ODM Production

- Premium Flame-Retardant Waterproof Safety Boots and Shoes

- Puncture-Resistant Velcro Safety Boots for Wholesale & Custom Manufacturing

- Premium KPU Athletic Safety Shoes for Wholesale

People Also Ask

- What are the cons of Cement Construction? The Hidden Costs of Glued Shoes

- What are the advantages of soft-toe boots? Superior comfort and flexibility for low-hazard work.

- Why are work boots considered essential PPE? Unlock Superior Foot Protection for Your Workforce

- How should work boots be stored when not in use? Protect Your Investment and Extend Their Lifespan

- What safety advantages do insulated boots offer beyond warmth? Dielectric Protection & Superior Grip

- How can workers improve the comfort of ill-fitting work boots temporarily? Quick Fixes for Immediate Relief

- What work boot features are important for logging and forestry work? Prioritize Certified Cut Resistance & Traction

- What materials are commonly used for the upper part of work boots? Full-Grain Leather vs. Synthetics Explained