In short, composite toe shoes are the standard choice for environments where metal is a liability or a nuisance. They are most commonly used by electricians and airport or security personnel who must frequently pass through metal detectors.

The decision to use composite toe footwear is fundamentally about its non-metallic properties. This makes it ideal for specific electrical and security applications, but it requires understanding its unique trade-offs compared to traditional steel toes.

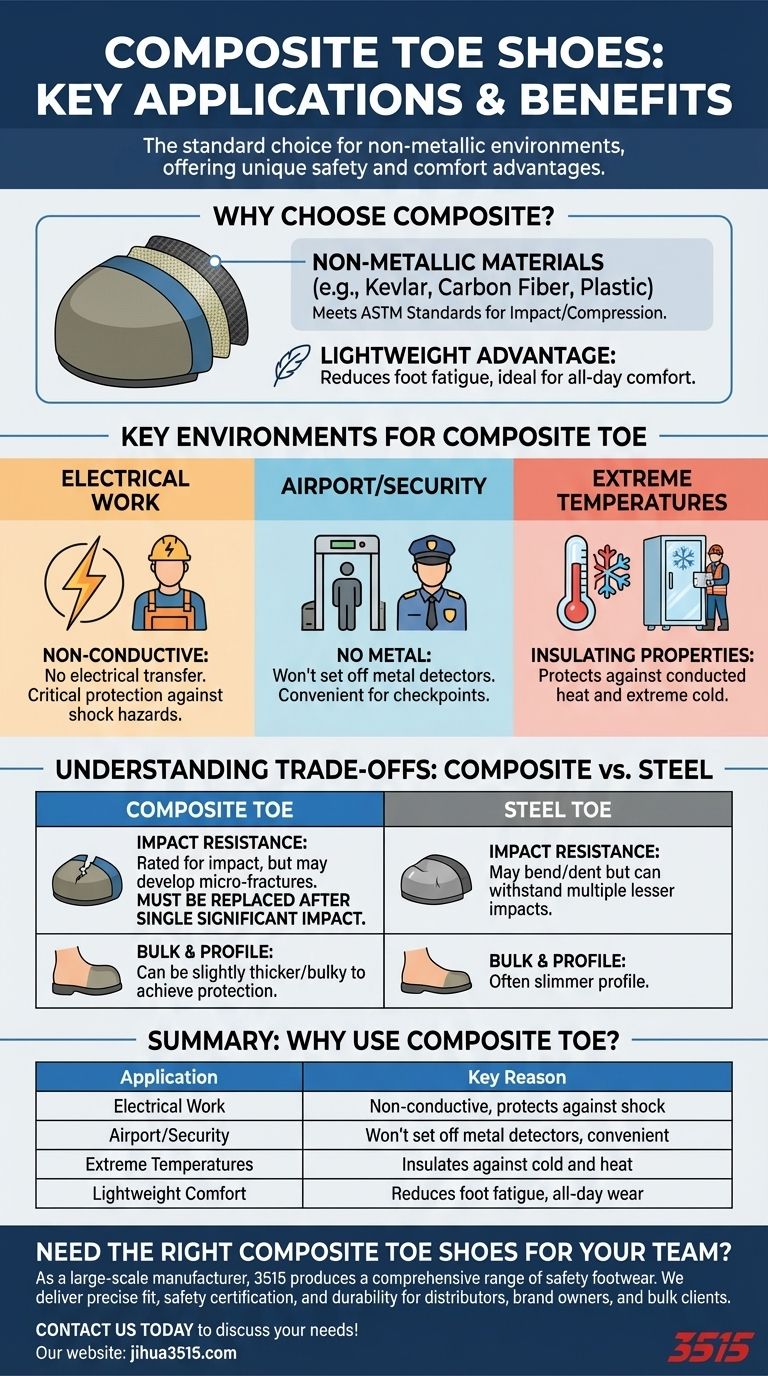

Why Material Defines the Application

The term "composite toe" refers to the non-metallic material used for the protective cap in a safety shoe. This design choice is the source of all its primary benefits and limitations.

What "Composite" Actually Means

A composite toe cap is typically made from a blend of non-metallic materials like Kevlar, carbon fiber, plastic, or fiberglass.

This construction is engineered to meet the same ASTM International safety standards for impact and compression resistance as a steel toe cap.

The Lightweight Advantage

Because these materials are significantly lighter than steel, composite toe shoes reduce foot fatigue over a long workday.

This makes them a preferred option for workers who are on their feet for extended periods and value all-day comfort.

Key Environments for Composite Toe Footwear

The unique properties of composite materials make these shoes the superior or only choice in several specific work environments.

Working Around Live Currents

For electricians, utility workers, and anyone working near live electrical currents, non-metallic footwear is critical.

Composite toes are non-conductive, meaning they do not transfer electricity. This provides an essential layer of protection against electrical shock hazards where a steel toe would introduce a significant risk.

Passing Through Security Checkpoints

Composite toe shoes contain no metal, so they will not set off metal detectors.

This is a major practical benefit for workers in airports, secure government buildings, and other high-security facilities who would otherwise have to remove their footwear repeatedly.

Comfort in Extreme Temperatures

Metal is an excellent conductor of temperature, but composite materials are not.

In extremely cold weather, a steel toe can become dangerously cold, while a composite toe remains insulated. Similarly, it provides better protection from conducted heat in very hot environments.

Understanding the Trade-offs: Composite vs. Steel

While composite toes offer clear advantages, they are not universally superior to steel toes. The choice involves understanding key differences in performance and durability.

Impact Resistance and Durability

Both steel and composite toes are rated to withstand the same minimum impact force. However, they behave differently under stress.

Steel can often bend or dent under impact and may withstand multiple lesser impacts. A composite toe, after a single significant impact, can develop micro-fractures that compromise its integrity, even if no damage is visible.

For this reason, a composite toe boot must be replaced after it has sustained a major impact.

Bulk and Profile

To achieve the same level of protection as steel, a composite cap often needs to be slightly thicker and bulkier.

This can sometimes make the toe box of the shoe feel larger, which is a matter of personal fit and preference.

Making the Right Choice for Your Role

Selecting the proper safety toe requires matching the material's properties to the specific hazards and demands of your job.

- If your primary focus is electrical hazard protection: Composite toe is the only safe and appropriate choice.

- If your primary focus is passing through metal detectors: Composite toe offers unmatched convenience and efficiency.

- If your primary focus is all-day comfort in extreme temperatures: The insulating properties and lighter weight of composite are a significant advantage.

- If your primary focus is work in heavy-duty environments with frequent impact risk: You must be prepared to replace composite footwear after any significant protective event.

Ultimately, choosing the right safety toe is about aligning the material's inherent strengths with the unique demands of your work environment.

Summary Table:

| Application | Key Reason for Using Composite Toe |

|---|---|

| Electrical Work | Non-conductive, protects against electrical shock |

| Airport/Security | Won't set off metal detectors, convenient for checkpoints |

| Extreme Temperatures | Insulates against cold and heat, unlike conductive steel |

| Lightweight Comfort | Reduces foot fatigue for workers on their feet all day |

Need the right composite toe shoes for your team?

As a large-scale manufacturer, 3515 produces a comprehensive range of safety footwear for distributors, brand owners, and bulk clients. Whether you need composite toe boots for electricians, security personnel, or any specialized role, we can deliver the precise fit, safety certification, and durability you require.

Contact us today to discuss your specific needs and get a quote for your next order!

Visual Guide

Related Products

- Premium KPU Athletic Safety Shoes for Wholesale

- Durable Rubber-Soled Utility Shoes for Wholesale & Custom Brand Manufacturing

- Wholesale Durable & Breathable Training Shoes for Custom Brands

- Wholesale Breathable Training Shoes Custom Athletic Footwear Manufacturer

- Wholesale Breathable & Cushioned Training Shoes Custom Factory Production

People Also Ask

- How does the anti-smashing feature of safety shoes protect technicians? Expert Guide to Ladder Setup Safety

- What comfort features are included in safety shoes? Key Elements for All-Day Wear

- What are the technical advantages of industrial-grade slip-resistant safety shoes? Prevent Falls with Engineered Grip

- What are the performance advantages of using EVA as an outsole material? Enhancing Safety Shoe Grip and Comfort

- What is the purpose of the skiving process for leather components in safety shoe manufacturing? Enhance Fit and Durability

- What are oil resistant safety boots? Your Guide to Slip-Resistant Footwear

- What factors should employers consider when selecting safety footwear? A Guide to Workplace Safety

- What are the characteristics of dual-density outsoles? Superior Safety Meets All-Day Comfort