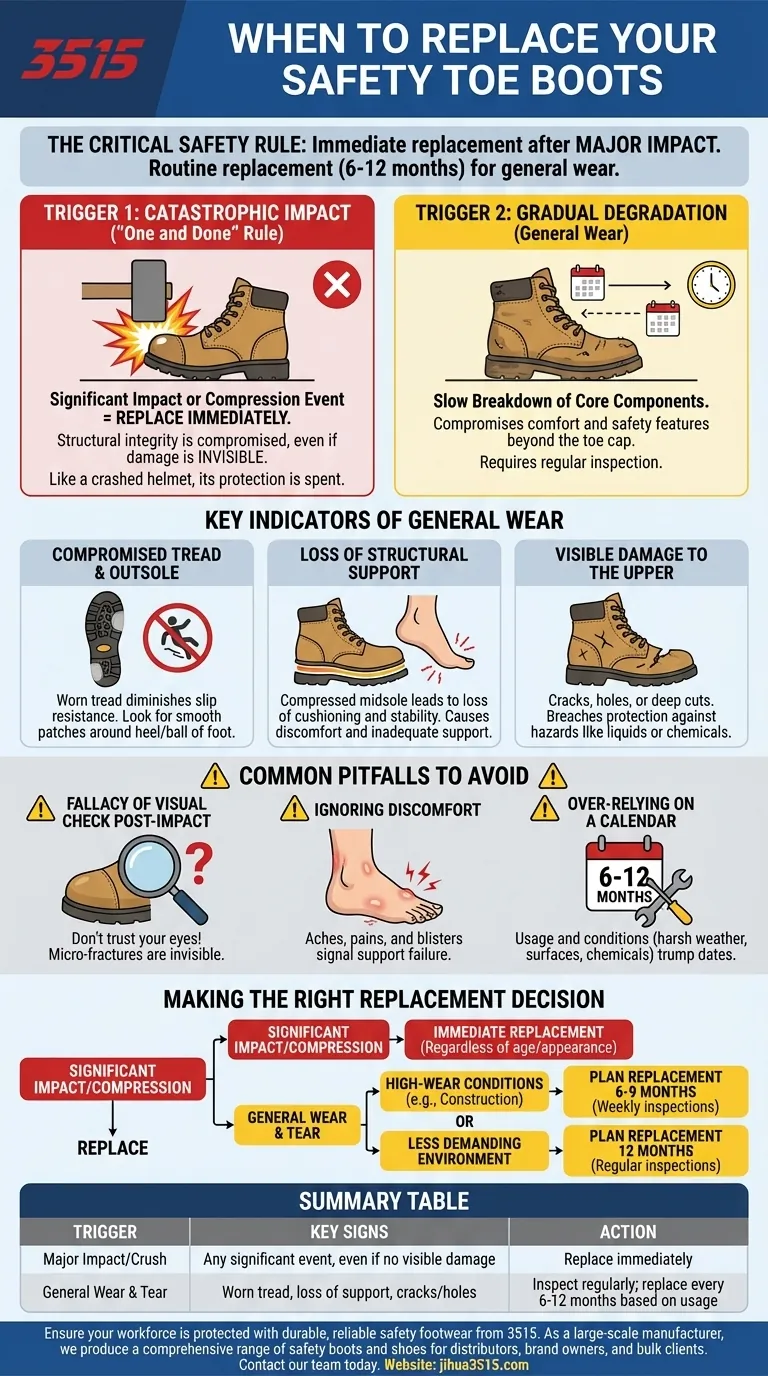

Knowing when to replace your safety toe boots is a critical safety decision. The most important rule is non-negotiable: you must replace the footwear immediately if the safety toe experiences a significant impact or compression event. Beyond that, general wear and tear dictates a more routine replacement schedule, typically every 6 to 12 months, to ensure the boot's overall structural integrity remains intact.

The core principle is simple: a safety toe has a zero-tolerance policy for major impacts. For all other situations, the boot's overall condition—from the sole's tread to its structural support—is the true measure of its remaining service life.

The Two Triggers for Replacement: Impact vs. Wear

Understanding when to replace your boots requires evaluating two distinct types of failure: catastrophic impact and gradual degradation. Each has its own set of rules.

The "One and Done" Rule for Impact

Any safety toe that has been subjected to a significant impact, crush, or compression event has done its job and must be retired.

The structural integrity of the toe cap—whether it's steel, composite, or alloy—is compromised after such an event. This damage is often invisible to the naked eye, but the material's ability to withstand a future impact is severely reduced.

Think of it like a motorcycle helmet after a crash. Even if it looks fine, it must be replaced because its protective capacity has been spent.

The Gradual Degradation of Wear

More commonly, boots are retired due to the slow breakdown of their core components. This general wear compromises not just comfort but also crucial safety features beyond the toe cap.

Regularly inspecting your boots for these signs of degradation is essential for preventing injury and ensuring you remain protected.

Key Indicators of General Wear

Look for these clear signals that your boots have reached the end of their functional life. These factors are just as important as the integrity of the toe cap itself.

Compromised Tread and Outsole

The texture on the bottom of your boot is critical for slip resistance. Once the tread pattern begins to wear smooth, especially around the heel or the ball of the foot, your protection against slips and falls is significantly diminished.

Loss of Structural Support

The midsole provides cushioning and support. Over time, it compresses and degrades, leading to a loss of support for your feet, ankles, and even your back. If your boots no longer feel supportive or you experience new rubbing or irritation, the internal structure has likely failed.

Visible Damage to the Upper

Cracks, holes, or deep cuts in the leather or synthetic upper are clear signs that the boot needs to be replaced. These breaches compromise the boot's ability to protect you from liquids, chemicals, or other workplace hazards. Separation between the upper and the sole is another critical failure point.

Understanding the Common Pitfalls

Even with clear guidelines, users often wait too long to replace their safety footwear. Avoiding these common mistakes is key to staying safe.

The Fallacy of Visual Inspection Post-Impact

Do not trust your eyes to judge a safety toe's integrity after an impact. A steel toe may have a small dent, and a composite toe may show no damage at all, but both can have micro-fractures that render them useless in a subsequent event. The risk is simply not worth it.

Ignoring Discomfort

Discomfort is a data point. New aches, pains, blisters, or excessive rubbing are direct signals that the boot's fit and support systems have broken down. Ignoring these signs can lead to chronic foot problems or even acute injuries.

Over-Relying on a Calendar Schedule

The 6-12 month recommendation is a baseline, not a guarantee. Working in exceptionally harsh weather, on abrasive surfaces like concrete, or with heavy chemicals will accelerate a boot's breakdown. Your actual usage and working conditions should always take precedence over a calendar date.

Making the Right Replacement Decision

Use your specific work environment and goals to determine your replacement strategy.

- If your boot has sustained a significant impact or compression: Replace it immediately, regardless of its age or outward appearance.

- If you work in high-wear conditions (e.g., construction, manufacturing): Plan for replacement every 6 to 9 months and perform weekly visual inspections.

- If your work environment is less demanding: A 12-month replacement cycle is a reasonable baseline, but you must still inspect regularly for signs of tread wear and loss of support.

Ultimately, your safety footwear is a critical piece of equipment, and treating it with a proactive and informed approach ensures it will always protect you when you need it most.

Summary Table:

| Replacement Trigger | Key Signs | Recommended Action |

|---|---|---|

| Major Impact/Crush | Any significant impact event, even if no visible damage | Replace immediately |

| General Wear & Tear | Worn-down tread, loss of support, cracks/holes in upper | Inspect regularly; replace every 6-12 months based on usage |

Ensure your workforce is always protected with durable, reliable safety footwear from 3515. As a large-scale manufacturer, we produce a comprehensive range of safety boots and shoes for distributors, brand owners, and bulk clients. Our production capabilities encompass all types of protective footwear designed to meet the highest safety standards. Don't compromise on safety—contact our team today to discuss your specific needs and secure a trusted supply of high-quality safety footwear.

Visual Guide

Related Products

- Wholesale Safety Footwear Manufacturer for Bulk & Custom OEM Orders

- Heavy-Duty Waterproof Nubuck Safety Boots Safety Shoes for Bulk Supply

- Premium Waterproof Nubuck Safety Boots for Wholesale

- Premium Wholesale Wheat Nubuck Safety Boot with Rapid Lacing System

- Premium Grain Leather Safety Boots for Bulk Supply

People Also Ask

- What are the different types of protection standards for safety footwear? Decode ASTM & EN ISO Standards

- Why is it necessary to reference ANSI and ASTM standards when evaluating safety footwear? Guide to Certified Protection

- What are the characteristics of alloy toe boots? The Ultimate Guide to Lightweight Safety Footwear

- How does the perceived value of Safety Shoes influence consumer repeat purchase behavior in the context of design? - 3515

- What are some examples of work environments where safety shoes are mandatory? Protect Your Workforce

- How does a drop hammer impact testing apparatus ensure standardization? Mastering Safety Shoe Certification Physics

- What dual roles do specialized medical-grade shoes play? Protect Staff & Process Integrity in Sterilization Zones

- What are the key requirements for ASTM F2413 conforming safety footwear? A Guide to Selecting the Right Protection