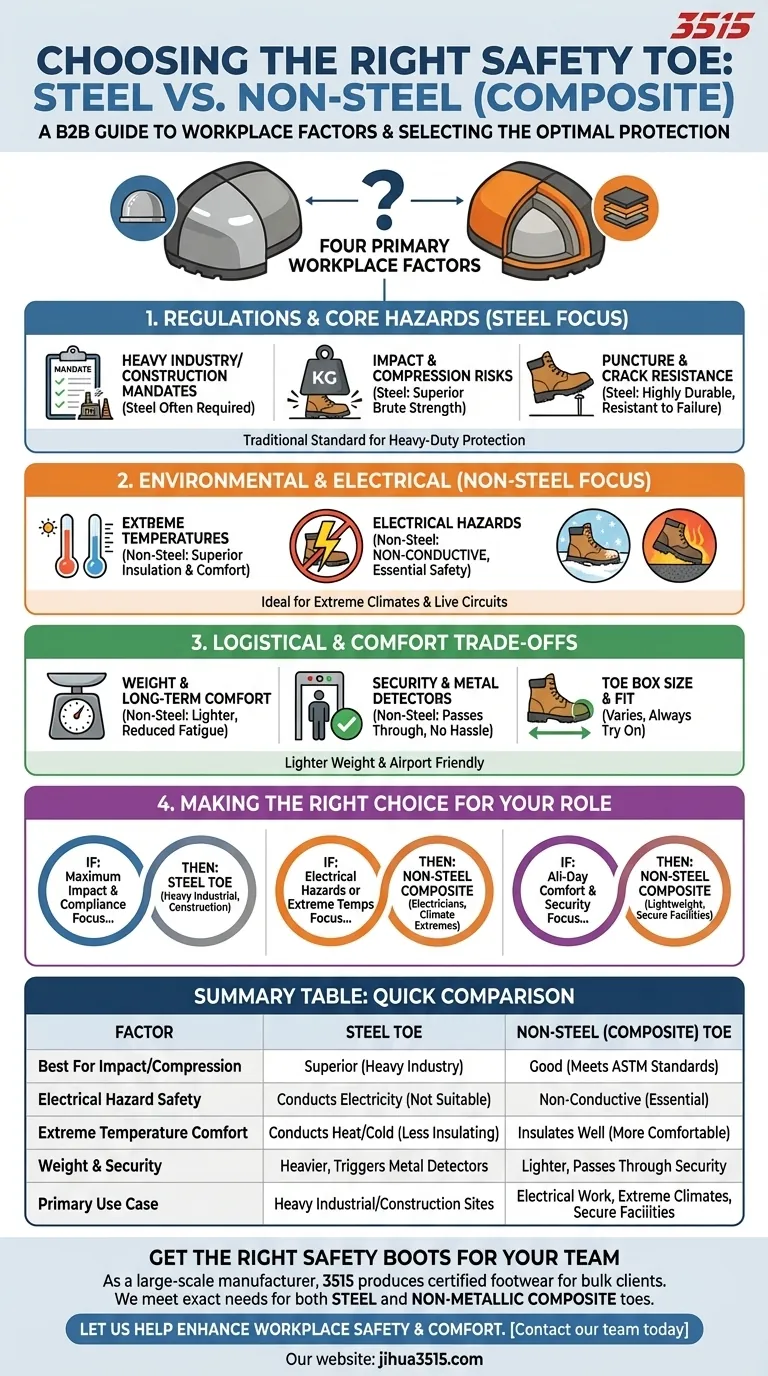

Choosing between steel and non-steel safety toes is determined by four primary workplace factors: mandatory regulations, specific job hazards, environmental conditions, and logistical considerations. While both are designed to protect you from impact and compression, understanding their key differences is essential for selecting the right tool for the job.

While both steel and non-steel toes meet fundamental ASTM safety standards, the optimal choice depends on a nuanced analysis of your work environment. Steel offers maximum brute strength, while non-steel materials excel in environments with electrical hazards, extreme temperatures, or frequent security screenings.

The Foundation: Regulations and Core Hazards

Workplace Mandates

The first and most critical factor is your site's safety policy. Some job sites, particularly in heavy industry or construction, explicitly mandate steel toe boots as a requirement for entry. If a specific type of protection is required, that decision supersedes all other factors.

Impact and Compression Risks

Steel is the traditional standard for heavy-duty protection. Its inherent strength provides exceptional resistance to crushing forces and high-impact events, making it a reliable choice in environments with heavy machinery or falling objects.

Puncture and Crack Resistance

Steel's durability also makes it highly resistant to cracking or shattering under extreme force. This provides an added layer of security that the protective toe cap will not fail during a critical incident.

Environmental and Electrical Considerations

Extreme Temperatures (Hot or Cold)

This is a key area where non-steel toes have a clear advantage. As a metal, steel is a highly effective thermal conductor. In cold environments, it draws heat away from your feet, and in hot environments, it can become uncomfortably warm. Non-steel composite toes provide superior insulation, helping maintain a stable and comfortable temperature inside the boot.

Electrical Hazards

For electricians or anyone working near live circuits, this is a non-negotiable safety factor. Steel conducts electricity, creating a significant risk. Non-metallic, composite safety toes are non-conductive and are the only appropriate choice for these roles.

Understanding the Trade-offs

Weight and Long-Term Comfort

Non-steel safety toes are generally lighter than steel. While the difference may seem minor, it can significantly reduce foot fatigue over a long shift, especially for workers who are constantly on their feet or walk long distances.

Security and Metal Detectors

A major logistical benefit of non-steel toes is that they do not trigger metal detectors. For employees at airports, secure government facilities, or other locations with security checkpoints, this eliminates a daily hassle and saves considerable time.

Toe Box Size and Fit

While not a universal rule, steel toe caps can sometimes allow for a larger, more spacious toe box within the boot's design. However, the most important factor is always trying on the boot to ensure a proper fit, regardless of the material.

Making the Right Choice for Your Role

Ultimately, the goal is to match the boot's features to your specific work realities.

- If your primary focus is maximum impact resistance and site compliance: A steel toe boot is the definitive choice, especially when mandated or in heavy industrial or construction settings.

- If your primary focus is working with electrical hazards or in extreme temperatures: Non-metallic composite toes are essential for their non-conductive and insulating properties.

- If your primary focus is all-day comfort and passing through security: A lighter-weight non-steel option is the superior choice to reduce fatigue and streamline access.

By evaluating your specific workplace realities, you can move beyond a simple comparison and select the safety toe that offers the most effective protection for your daily tasks.

Summary Table:

| Factor | Steel Toe | Non-Steel (Composite) Toe |

|---|---|---|

| Best For Impact/Compression | Superior (Heavy Industry) | Good (Meets ASTM Standards) |

| Electrical Hazard Safety | Conducts Electricity (Not Suitable) | Non-Conductive (Essential) |

| Extreme Temperature Comfort | Conducts Heat/Cold (Less Insulating) | Insulates Well (More Comfortable) |

| Weight & Security | Heavier, Triggers Metal Detectors | Lighter, Passes Through Security |

| Primary Use Case | Heavy Industrial/Construction Sites | Electrical Work, Extreme Climates, Secure Facilities |

Get the Right Safety Boots for Your Team

As a large-scale manufacturer, 3515 produces a comprehensive range of certified safety footwear for distributors, brand owners, and bulk clients. Whether your worksite demands the maximum protection of steel toe boots or the specialized benefits of non-metallic composite toes, we have the production capabilities and expertise to meet your exact needs.

Let us help you enhance workplace safety and comfort. Contact our team today to discuss your requirements and get a quote!

Visual Guide

Related Products

- Custom Safety Shoe Manufacturer for Wholesale & OEM Brands

- Premium Lightweight Safety Shoes for Wholesale & Bulk Orders

- Wholesale Durable Breathable Safety Boots Custom OEM Manufacturer

- Premium KPU Athletic Safety Shoes for Wholesale

- Wholesale Leather Safety Boots with Customizable Protective Toe

People Also Ask

- What protection do steel toe boots provide? Essential Safety for Hazardous Work

- What are the different types of steel toe work boots? Choose the Right Boot for Your Job

- What are the disadvantages of wearing steel-toe boots? Heavy Weight, Discomfort & Safety Risks

- Why is it mandatory to wear safety shoes with steel toe protection during metal loading? Prevent Crushing Injuries

- What is the difference between safety toe and steel toe work boots? Choose the right protection for your job.

- What common myth about steel toe caps is addressed in the article? Debunking the Amputation Fear

- Why might someone choose a composite toe boot over a steel toe boot? Lighter, Safer, and More Comfortable.

- What are the characteristics of a properly fitting steel toe boot? Achieve All-Day Safety and Comfort