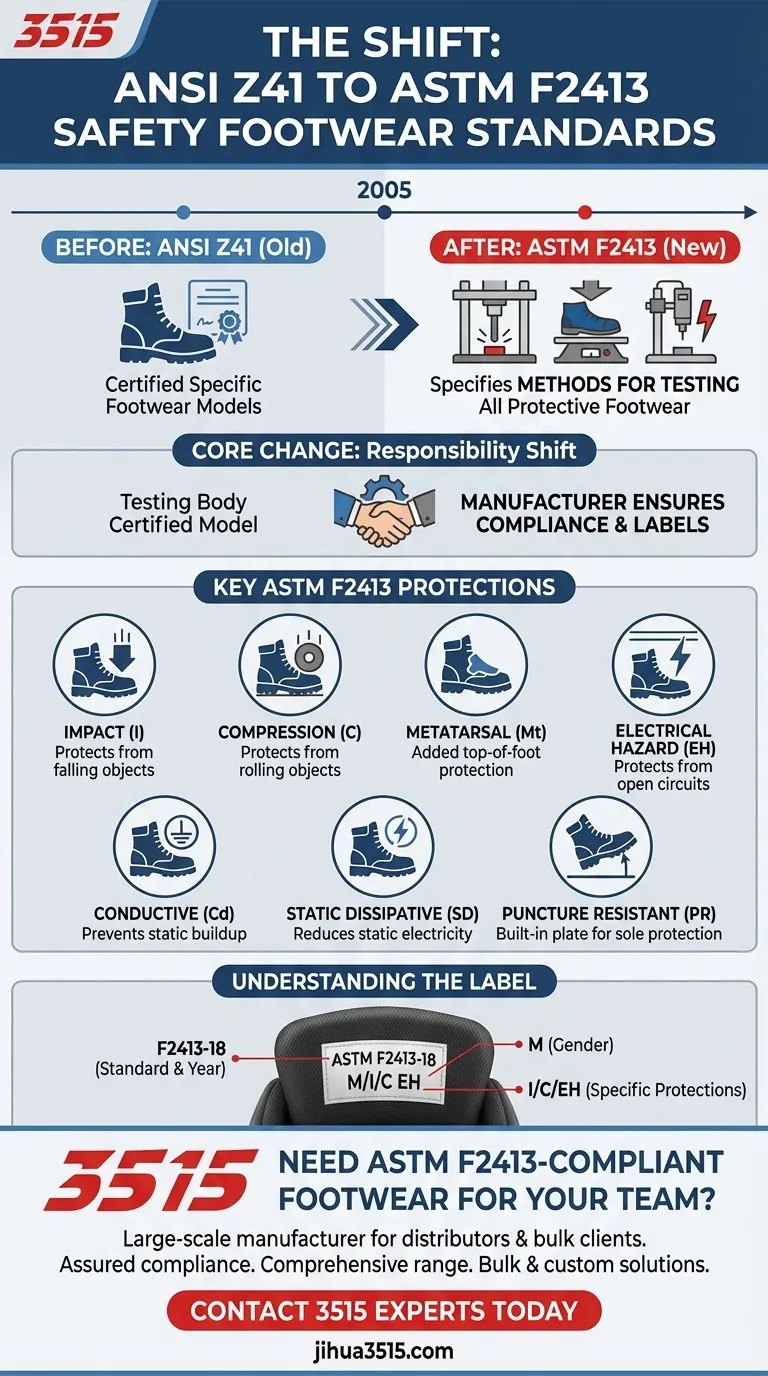

In 2005, the ASTM F2413 standard was introduced to replace the withdrawn ANSI Z41 standard. This change marked a significant shift in how protective footwear is tested and certified in the United States, moving from a standard developed by the American National Standards Institute to one managed by ASTM International.

The core change was a move from a standard that certified specific footwear models (ANSI Z41) to a standard that governs the methods for testing all protective footwear (ASTM F2413). This puts the responsibility on manufacturers to ensure their products consistently meet these rigorous testing requirements.

The Evolution from ANSI to ASTM

To understand why this change occurred, it's essential to recognize the roles these organizations play and the philosophies behind their standards. The transition reflects a broader trend toward performance-based testing.

What was the ANSI Z41 Standard?

The ANSI Z41 standard was the long-standing benchmark for safety footwear in the U.S. It specified the design, performance, testing, and classification requirements that a specific boot or shoe had to meet to be considered "safety footwear."

Under this system, a particular model of footwear would be sent for testing. If it passed, that specific model was certified as compliant.

Why the Shift to ASTM F2413?

The move to ASTM International, an organization renowned for developing technical standards for materials, products, and services, streamlined the process. The new standard, ASTM F2413, established a set of performance requirements and, crucially, the methods for testing that footwear must undergo.

Instead of certifying individual shoe models, ASTM F2413 provides the testing playbook. It is now the manufacturer's responsibility to test their footwear against this standard and certify that it complies.

Key Protections Governed by ASTM F2413

The ASTM F2413 standard is not a single rule but a comprehensive specification covering various workplace hazards. Manufacturers test their products for specific protections and label the footwear accordingly.

Impact (I) and Compression (C) Resistance

This is the most fundamental requirement, pertaining to the safety toe cap.

- Impact (I): Measures the toe cap's ability to protect the foot from a falling object.

- Compression (C): Measures the toe cap's ability to protect the foot from a rolling object or compression force.

Metatarsal Protection (Mt)

This standard applies to footwear with added protection for the metatarsal bones, the area at the top of the foot. It is critical in environments where objects could drop or roll onto the foot.

Other Critical Protections

ASTM F2413 also provides testing standards for several other specialized hazards:

- Conductive (Cd): Protects against the hazards of static electricity buildup.

- Electrical Hazard (EH): Protects the wearer from open electrical circuits.

- Static Dissipative (SD): Reduces the buildup of static electricity by conducting it to the ground.

- Puncture Resistant (PR): Indicates a puncture-resistant plate is built into the sole to protect from sharp objects underfoot.

Understanding the Practical Implications

The transition from ANSI to ASTM has direct consequences for employers and workers selecting safety footwear. The focus is no longer on a simple "ANSI-approved" label but on understanding what specific protections a boot offers.

The Label is Your Guide

Every pair of ASTM-compliant footwear must have a label, typically on the inside of the tongue, that clearly specifies which standards it meets. A typical label might read: ASTM F2413-18 M/I/C EH.

This code tells you the footwear meets the 2018 version of the ASTM F2413 standard, is designed for a male (M), and is certified for Impact (I), Compression (C), and Electrical Hazard (EH) protection.

Manufacturer Responsibility

The current system places the burden of proof on the manufacturer. They must ensure their products meet the ASTM test methods and correctly label them. This performance-based approach encourages continuous improvement and clear communication about a product's capabilities.

How to Apply This to Your Safety Program

Choosing the right footwear requires matching the specific protections to the hazards identified in your workplace risk assessment.

- If your primary focus is general construction or warehouse work: You need footwear that, at a minimum, is rated for Impact (I) and Compression (C).

- If your workers are electricians or work near live circuits: You must select footwear specifically rated for Electrical Hazard (EH) protection.

- If your environment has sharp debris on the ground: Prioritize footwear with a Puncture Resistant (PR) rating.

- If you work with sensitive electronics or in flammable environments: Look for Static Dissipative (SD) or Conductive (Cd) ratings, depending on the specific need.

Ultimately, the shift from ANSI Z41 to ASTM F2413 empowered manufacturers and buyers with a clearer, more detailed system for verifying footwear protection.

Summary Table:

| Aspect | ANSI Z41 (Old) | ASTM F2413 (New) |

|---|---|---|

| Focus | Certified specific shoe models | Specifies testing methods for all footwear |

| Responsibility | Testing body certified the model | Manufacturer ensures compliance and labels |

| Key Protections | Impact, Compression | Impact (I), Compression (C), Metatarsal (Mt), Electrical Hazard (EH), Puncture Resistant (PR), and more |

| Label Example | ANSI Z41 Compliant | ASTM F2413-18 M/I/C EH |

Need Reliable, ASTM F2413-Compliant Footwear for Your Team?

As a large-scale manufacturer, 3515 produces a comprehensive range of certified safety footwear for distributors, brand owners, and bulk clients. Our production capabilities encompass all types of ASTM-compliant safety shoes and boots, ensuring your workforce is protected against specific workplace hazards.

We provide:

- Assured Compliance: All our protective footwear is rigorously tested to meet the latest ASTM F2413 standards.

- Comprehensive Range: From basic impact/compression protection to specialized EH, PR, and SD ratings.

- Bulk & Custom Solutions: Tailored manufacturing for large orders and private labeling.

Ensure your team's safety with footwear you can trust. Contact our experts today to discuss your requirements and receive a competitive quote!

Visual Guide

Related Products

- Safety Footwear Wholesale Manufacturer for Custom OEM/ODM Production

- Customizable Anti-Smash Safety Boots for Wholesale & Private Label Manufacturing

- Custom Wholesale Leather Safety Boots Direct Factory Manufacturing

- Premium Grain Leather Safety Boots for Bulk Supply

- Premium Wholesale Wheat Nubuck Safety Boot with Rapid Lacing System

People Also Ask

- Why can metal protective toecaps become a risk factor for dorsal foot ulcers? Learn to Prevent Pressure Point Injuries

- How do professional construction boots improve operational efficiency? Boost Site Productivity with Advanced Footwear

- What are the cultural perspectives on wearing shoes in the house? A Guide to Home Etiquette & Hygiene

- How do safety shoes contribute to cost savings for companies? A Strategic Investment in Risk and Cost Management

- How do industrial safety shoes provide protection for personnel? Safeguard Your Team from Heavy Crane Hazards