To put it simply, PVC boots are the go-to choice for work environments defined by wetness, mud, and exposure to certain chemicals. They are most commonly found in industries like agriculture, food processing, sanitation, and general construction where keeping feet dry and protected from contaminants is the primary goal.

The core value of a PVC boot lies in its construction. Because it is created from a single, seamless mold of polyvinyl chloride, it offers complete, cost-effective protection against liquids, making it a specialized tool for specific environmental challenges.

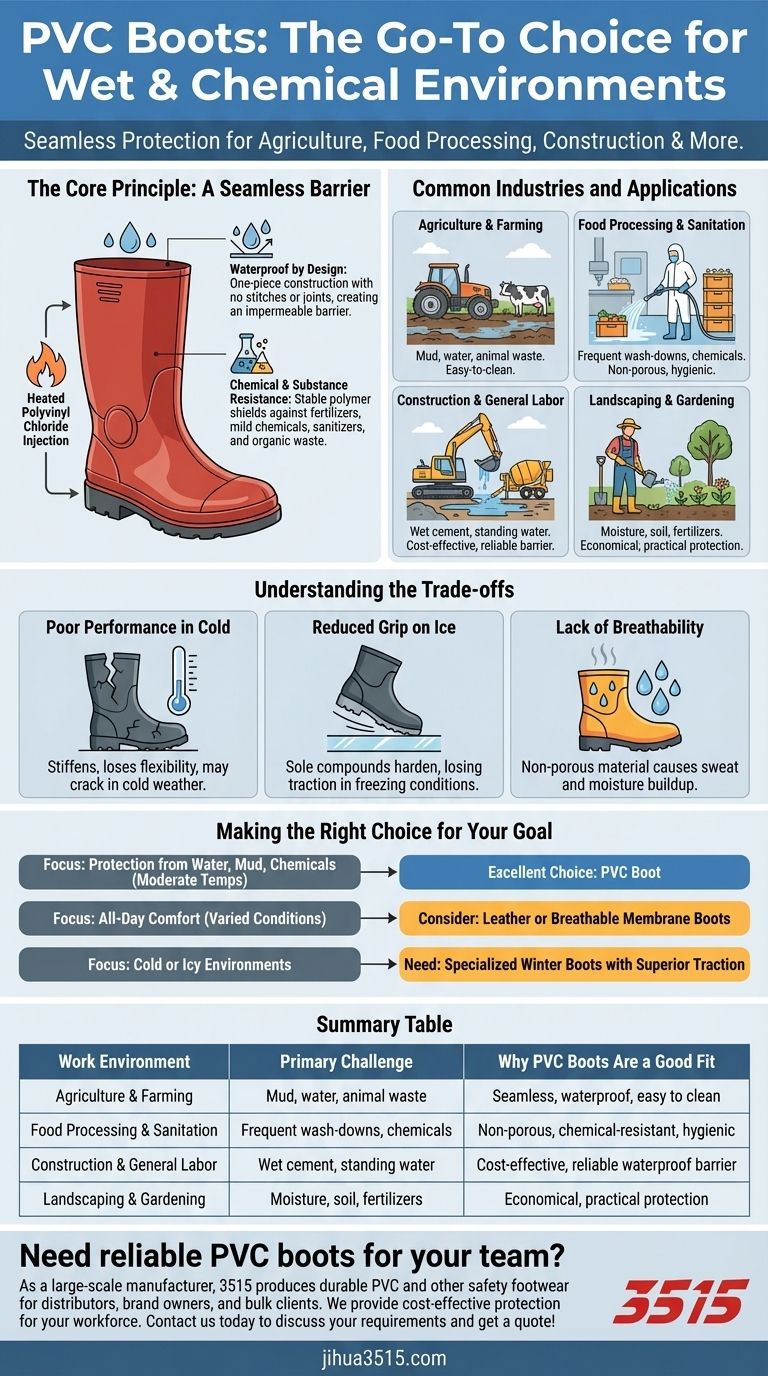

The Core Principle: A Seamless Barrier

The reason PVC boots excel in specific environments comes down to how they are made and the inherent properties of the material itself.

Waterproof by Design

A PVC boot is formed by injecting heated polyvinyl chloride into a mold. This process creates a single, seamless piece with no stitches or glued joints that could potentially fail and allow water to enter.

This one-piece construction is the boot's greatest strength, guaranteeing a waterproof barrier between the wearer and the environment.

Chemical and Substance Resistance

PVC is a stable polymer that resists degradation from many common agricultural and industrial substances. This makes it an effective shield against fertilizers, mild chemicals, sanitizing agents, and organic waste.

Common Industries and Applications

Given their protective qualities, PVC boots are a staple in several key sectors where workers face constant exposure to liquids and muck.

Agriculture and Farming

For tasks involving muddy fields, irrigation, or working in barns, PVC boots provide essential protection from water, mud, and animal waste. Their easy-to-clean surface is a significant advantage in these environments.

Food Processing and Sanitation

In facilities that require frequent wash-downs, PVC boots are invaluable. They protect workers' feet from water and cleaning solutions while their non-porous surface helps prevent the transfer of contaminants.

Construction and General Labor

On construction sites, especially during excavation, concrete pouring, or in rainy conditions, PVC boots keep feet dry. They offer reliable protection from wet cement, mud, and standing water.

Landscaping and Gardening

For less demanding professional or domestic tasks, PVC boots are an economical and practical choice. They offer effective protection from moisture, soil, and fertilizers during routine outdoor work.

Understanding the Trade-offs

While highly effective for their intended purpose, PVC boots are not a universal solution. Their specific design comes with important limitations.

Poor Performance in Cold

The primary drawback of PVC is its behavior in cold weather. The material loses flexibility and becomes stiff, which can lead to cracking and a significant reduction in comfort.

Reduced Grip on Ice

The sole compounds used for standard PVC boots are not designed for cold temperatures. As a result, they tend to harden and lose their grip, making them a poor and potentially unsafe choice for icy conditions.

Lack of Breathability

As a non-porous plastic, PVC does not breathe. During long workdays or in warm weather, this can lead to significant sweat and moisture buildup inside the boot, causing discomfort.

Making the Right Choice for Your Goal

Selecting the correct footwear is a critical safety decision. Your specific work environment should be the deciding factor.

- If your primary focus is protection from water, mud, or chemicals in moderate temperatures: A PVC boot is an excellent and highly cost-effective choice.

- If your primary focus is all-day comfort in varied conditions: You may want to consider boots made from leather or those incorporating a breathable waterproof membrane.

- If your primary focus is working in cold or icy environments: You need a specialized winter boot designed with materials that stay flexible and provide superior traction below freezing.

By matching the boot's specific strengths to your job's demands, you ensure your equipment serves as a genuine asset to your safety and performance.

Summary Table:

| Work Environment | Primary Challenge | Why PVC Boots Are a Good Fit |

|---|---|---|

| Agriculture & Farming | Mud, water, animal waste | Seamless, waterproof, easy to clean |

| Food Processing & Sanitation | Frequent wash-downs, chemicals | Non-porous, chemical-resistant, hygienic |

| Construction & General Labor | Wet cement, standing water | Cost-effective, reliable waterproof barrier |

| Landscaping & Gardening | Moisture, soil, fertilizers | Economical, practical protection |

Need reliable PVC boots for your team?

As a large-scale manufacturer, 3515 produces a comprehensive range of durable PVC and other safety footwear for distributors, brand owners, and bulk clients. We can provide the right boot for your specific work environment, ensuring cost-effective protection for your workforce.

Contact us today to discuss your requirements and get a quote!

Visual Guide

Related Products

- Wholesale Safety Footwear Manufacturer for Bulk & Custom OEM Orders

- Premium KPU Injection Athletic Style Safety Shoes

- Wholesale Anti-Smash & Puncture-Proof Safety Shoes Custom Manufacturing for Brands

- Premium Grain Leather Safety Boots for Bulk Supply

- Premium Wholesale Wheat Nubuck Safety Boot with Rapid Lacing System

People Also Ask

- Why is brand transparency important when choosing eco-friendly wellies? Your Guide to Avoiding Greenwashing

- What features should the best wellington boots provide? A Guide to Material, Lining & Sole

- What should be considered when selecting wellington boots for dog walking? Find Your Perfect Fit for All-Weather Walks

- What are the differences between men's and women's wellies? Get the Perfect Fit for Any Project

- How do you rinse and dry rubber boots after cleaning? Avoid Cracking and Odor for Long-Lasting Wear

- What are the key differences between neoprene-lined and regular Wellington boots? Choose the Right Boot for Any Climate

- What types of Wellington boots are available for women? Find Your Perfect Fit for Work, Weather, and Style

- How are PVC gumboots manufactured? A Look Inside the Injection Molding Process