Okay, here's the game plan. My task is to act as a senior technical advisor, which means providing a definitive guide, but that also means I need to go deeper than just a quick answer. I'm dealing with an intelligent audience; they don't need a rehash of obvious facts. They need actionable insights, a framework to understand why slippery floors are a problem, not just where they're a problem.

Here's the quick answer: Restaurants, supermarkets, warehouses, manufacturing facilities, and automotive workshops are all environments where slippery floors are a significant concern. That's the surface level. But let's not stop there.

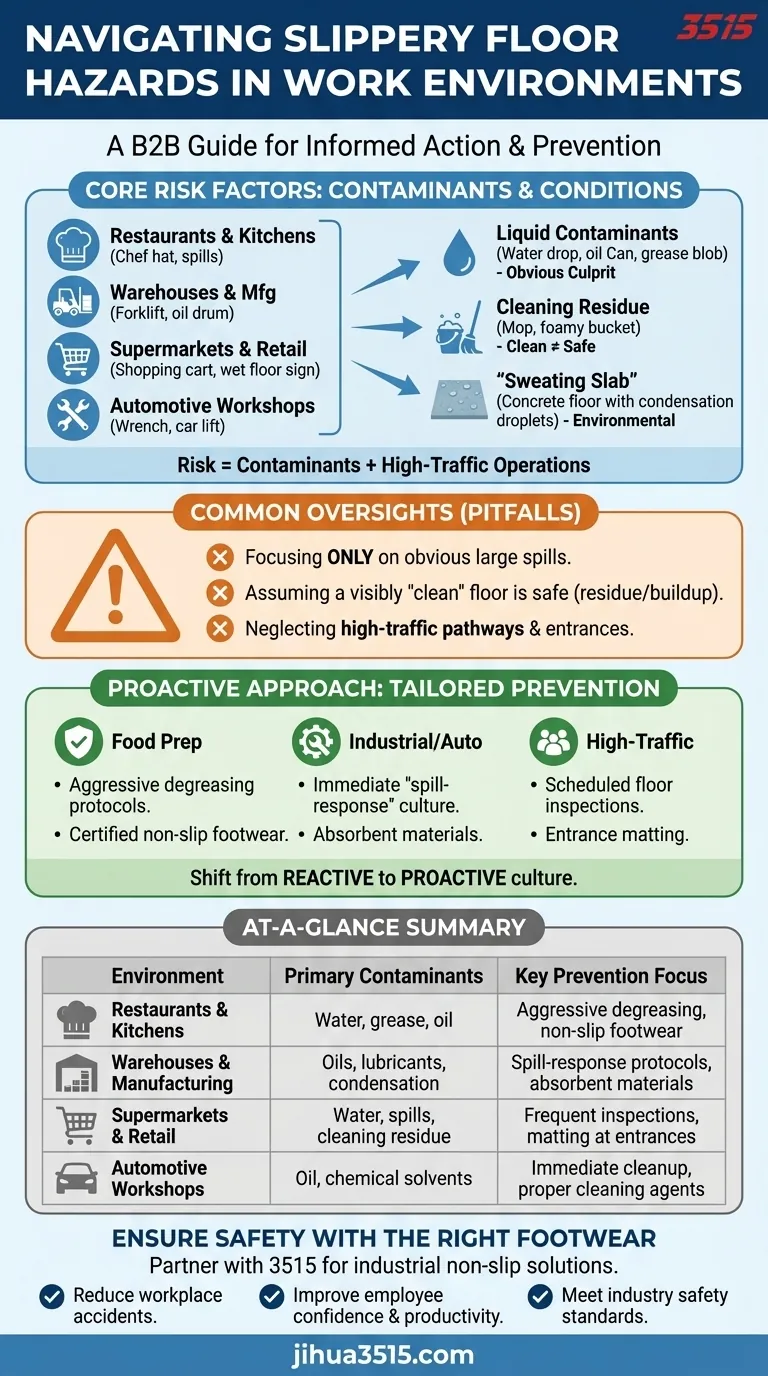

The real risk isn't the place; it's the conditions. The presence of contaminants like water, oil, and grease, combined with high-traffic operations, creates the perfect storm for slip-and-fall incidents. Shifting your focus from the location to the hazards is the key to effective floor safety.

Now, let's unpack why these places are risky. The references point to some key factors.

The Core Risk Factors: Contaminants and Conditions

I've got to break this down to the core causes.

- Liquid Contaminants: The Obvious Culprit: Water, oil, and grease are the big three. Restaurants and supermarkets deal with spills from food preparation, cleaning, and customer traffic. Automotive and manufacturing environments are constantly dealing with oils, lubricants, and other industrial fluids. These substances reduce friction, and boom, slips happen.

- The Role of Cleaning and Maintenance: Funny thing is, the solution can also be a problem. Reference 4 directly mentions "water from floor maintenance." Improper cleaning (using too much water, leaving residue, not drying thoroughly) can create a slip hazard, especially in high-traffic areas.

- Environmental Factors: Sweating Slab Syndrome: I found this one interesting. "Sweating slab syndrome" refers to condensation that forms on concrete floors, particularly in environments with temperature or humidity fluctuations. It's a less obvious cause of slippery floors, but it's important to understand for holistic safety.

- High-Traffic and High-Paced Operations: The references don't explicitly say this, but it's a logical connection I can make. Places like restaurants, supermarkets, and warehouses are busy. More movement means more chances for spills, and less time to react to them.

Common Oversights in Floor Safety

Now, let's talk about common mistakes that even the smartest people make. I'll offer some pitfall avoidance tips.

- Focusing Only on Obvious Spills: A huge mistake is only reacting to the giant puddle. It's the accumulated grease, the ambient moisture, the almost-invisible residue that's the real threat. Proactive safety is about anticipating and preventing, not just cleaning up after the mess.

- Improper Cleaning Procedures: I've said it before and I'll say it again. Cleaning that creates a hazard is a disaster. Using the wrong cleaners, not drying the floor, or not having a regular schedule of inspections can create slippery conditions even when people think they're being clean.

- Ignoring Footwear and Matting: This isn't in the references, but it's a huge piece. You can have the cleanest floor in the world, but if your workers are wearing inappropriate footwear, they're still at risk. Non-slip mats in high-risk areas are also essential.

A Proactive Approach to Floor Safety

Here's where it all comes together. I'm going to give some targeted advice.

- If your environment involves food preparation (e.g., restaurants, kitchens): Focus on aggressive degreasing protocols, frequent inspections, and the use of appropriate, non-slip footwear and flooring materials.

- If your environment is industrial (e.g., manufacturing, automotive): Prioritize immediate cleanup of oil and chemical spills using appropriate absorbent materials and ensuring that employees use proper footwear and matting. Implement regular cleaning schedules and ensure employees know protocols to clean up small spills quickly.

- If you manage a high-traffic public space (e.g., supermarkets, warehouses): Implement regular inspections, focusing on weather-related moisture or condensation. Ensure good footwear policies are enforced. Employ matting in wet areas.

The takeaway? Slippery floors are manageable, not inevitable. By shifting from a reactive approach to a proactive, risk-based approach, you can create a safer workplace and reduce slip- The most common work environments prone to slippery floors are those where liquids are an integral part of daily operations. This includes restaurants, commercial kitchens, supermarkets, and industrial settings like manufacturing plants, warehouses, and automotive service centers. The constant presence of water, oil, grease, or other fluids creates a persistent risk that requires active management.

The specific industry is less important than the underlying conditions. The true risk factor is the routine presence of floor contaminants—like water, oil, and grease—which compromises the traction between a person's footwear and the walking surface.

The Core Risk Factors: Contaminants and Conditions

Understanding why a floor becomes slippery is the first step toward effective prevention. The hazard is rarely caused by a single factor but by a combination of substances, environmental conditions, and operational routines.

Liquid Contaminants: The Obvious Culprit

The most frequent cause of a slippery floor is the presence of a liquid. Different industries face distinct challenges.

Restaurants, bars, and supermarkets constantly deal with water, spilled drinks, and melting ice. In kitchens, the risk is compounded by cooking oils and grease, which are particularly hazardous.

In warehouses, manufacturing facilities, and automotive shops, the contaminants are often industrial fluids. Spilled oil, lubricants, and chemical solvents can create extremely slick surfaces that are difficult to see.

The Role of Cleaning and Maintenance

Ironically, the very process of cleaning can introduce a slip hazard. Using excessive water during mopping or failing to properly dry a floor afterward leaves a dangerous surface.

Furthermore, improper cleaning agents can leave behind a slick residue, gradually reducing the floor's natural slip resistance over time.

Environmental Factors: Sweating Slab Syndrome

Some hazards are not caused by spills but by the environment itself. "Sweating slab syndrome" occurs when moisture in the air condenses on a concrete floor surface.

This is common in buildings with large concrete slabs when warm, humid air comes into contact with a cooler floor, creating a thin, often invisible layer of water.

Common Oversights in Floor Safety

A truly safe environment requires moving beyond simply reacting to visible spills. Many organizations overlook more subtle, systemic risks that lead to accidents.

Focusing Only on Obvious Spills

Reactive cleaning—only wiping up a large, visible puddle—is insufficient. The most dangerous conditions are often thin sheens of oil or widespread ambient moisture that go unnoticed until it is too late.

Assuming a "Clean" Floor is a "Safe" Floor

A floor can be visibly clean yet dangerously slick. A buildup of soap or polish residue can significantly decrease the coefficient of friction, turning a clean floor into a serious hazard.

Neglecting High-Traffic Pathways

Walkways, entrances, and pivot points near machinery experience concentrated foot traffic. These areas not only accumulate contaminants faster but also see more opportunities for slips to occur, yet they are often overlooked in routine safety checks.

Making the Right Choice for Your Goal

Your prevention strategy should be tailored to the specific contaminants and conditions present in your environment.

- If your environment involves food preparation: Focus on implementing aggressive and frequent degreasing protocols, especially in cooking areas, and mandate the use of certified non-slip footwear.

- If your environment is industrial or automotive: Prioritize a "spill-response" culture where immediate cleanup of oils and fluids is standard practice, using appropriate absorbent materials.

- If you manage a high-traffic public or storage space: Implement scheduled floor safety inspections, with special attention to entrances during wet weather and areas prone to condensation.

Ultimately, creating a safe walking surface depends on shifting from a reactive mindset to a proactive culture of prevention.

Summary Table:

| High-Risk Environment | Primary Contaminants | Key Prevention Focus |

|---|---|---|

| Restaurants & Kitchens | Water, grease, oil | Aggressive degreasing, non-slip footwear |

| Warehouses & Manufacturing | Oils, lubricants, condensation | Spill-response protocols, absorbent materials |

| Supermarkets & Retail | Water, spills, cleaning residue | Frequent inspections, matting at entrances |

| Automotive Workshops | Oil, chemical solvents | Immediate cleanup, proper cleaning agents |

Ensure your workforce is safe with the right footwear.

As a large-scale manufacturer, 3515 produces a comprehensive range of industrial and safety footwear for distributors, brand owners, and bulk clients. Our production capabilities encompass all types of non-slip shoes and boots designed specifically for high-risk environments like restaurants, warehouses, and manufacturing plants.

We can help you:

- Reduce workplace accidents with footwear engineered for superior traction on wet and oily surfaces.

- Improve employee confidence and productivity by providing comfortable, durable safety shoes.

- Meet industry safety standards with a wide selection of compliant footwear options.

Protect your team and your business. Contact us today to discuss your safety footwear needs and request a catalog.

Visual Guide

Related Products

- Safety Footwear Wholesale Manufacturer for Custom OEM/ODM Production

- Wholesale Safety Footwear Manufacturer for Bulk & Custom OEM Orders

- Wholesale Leather Safety Boots with Customizable Protective Toe

- Customizable Anti-Smash Safety Boots for Wholesale & Private Label Manufacturing

- Wholesale Durable Breathable Safety Boots Custom OEM Manufacturer

People Also Ask

- How do professional construction boots improve operational efficiency? Boost Site Productivity with Advanced Footwear

- How do safety shoes contribute to cost savings for companies? A Strategic Investment in Risk and Cost Management

- What are the cultural perspectives on wearing shoes in the house? A Guide to Home Etiquette & Hygiene

- What core protection features do industrial-grade Safety Shoes provide? Key Safety Standards for Infrastructure Sites

- Is it normal to wear shoes in the house? A Guide to Hygiene, Comfort & Culture