At its core, military textile selection revolves around advanced synthetic fabrics, with highly durable nylons serving as the foundation for most gear. These materials are not standard textiles; they are engineered specifically to be strong, rugged, lightweight, and fast-drying to meet the intense demands of operational environments.

The choice of a military fabric is never about a single "best" material. It is a calculated decision to match a specific set of engineered properties—such as abrasion resistance, flame retardancy, or ballistic protection—to the precise threats and environmental conditions of a given mission.

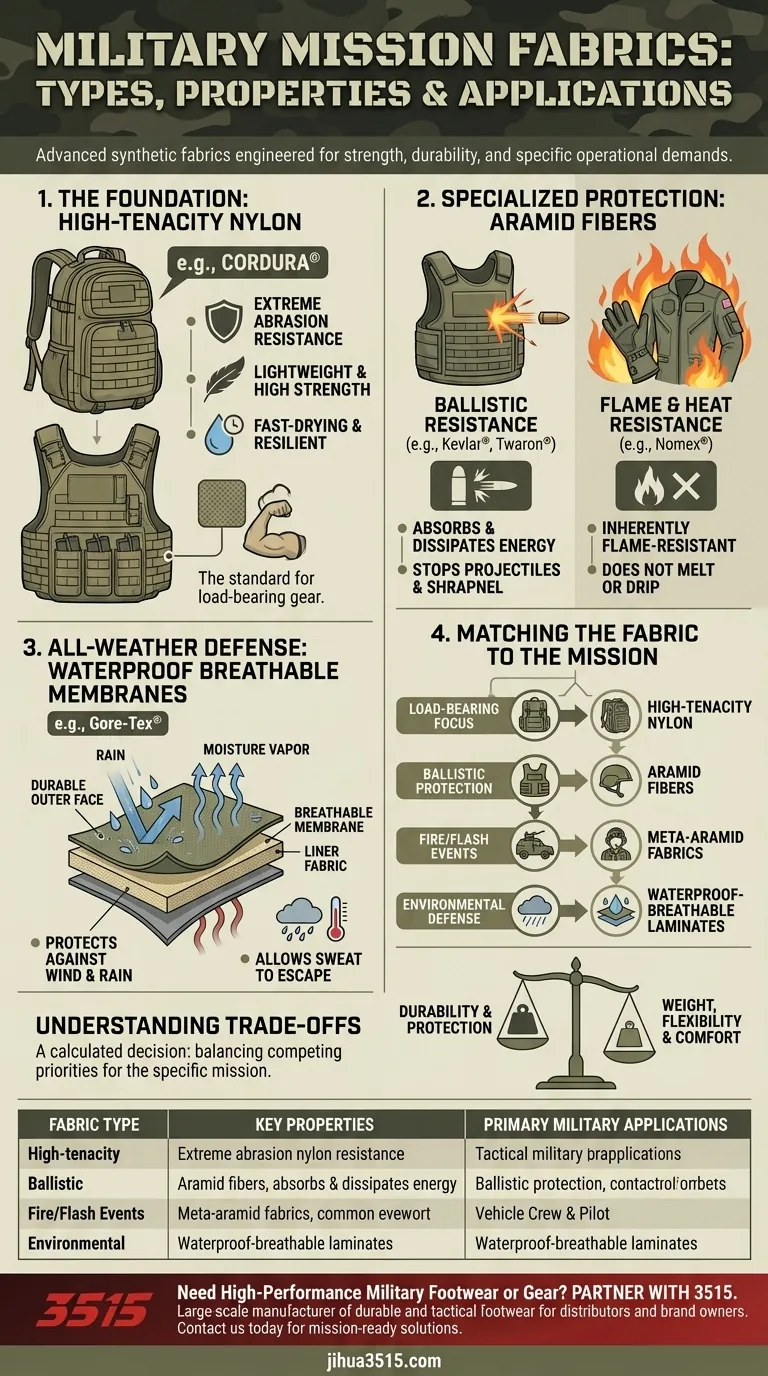

The Foundation: High-Tenacity Nylon

The most common material family in military gear is high-tenacity nylon. It forms the basis for everything from backpacks and pouches to uniform components.

What is High-Tenacity Nylon?

This is a category of nylon fiber, most famously represented by the brand CORDURA®, that has been specifically engineered for exceptional strength and durability. It achieves this through a specialized production process that creates a highly uniform fiber structure.

The Strength-to-Weight Ratio

The primary advantage of these nylons is their ability to provide extreme resistance to tears and abrasion while remaining remarkably lightweight. This is critical for reducing the overall load carried by personnel, directly impacting their mobility and endurance.

Environmental Resilience

Beyond simple toughness, these fabrics are designed to perform in harsh conditions. They are inherently resistant to rot and mildew and are often treated to be water-repellent. Their synthetic nature means they do not absorb much water and can dry very quickly.

Beyond Durability: Specialized Performance Fabrics

While nylon provides the structural backbone for most gear, specialized missions require fabrics with unique protective properties.

Ballistic Resistance: Aramid Fibers

For body armor and fragmentation protection, the military relies on aramid fibers like Kevlar® and Twaron®. These materials have a unique chemical structure that allows them to absorb and dissipate enormous amounts of energy, making them effective at stopping projectiles and shrapnel.

Flame and Heat Resistance: Meta-Aramids

Personnel who operate in high-risk fire environments, such as vehicle crews and pilots, wear gear made from meta-aramid fibers like Nomex®. This material is inherently flame-resistant; it will not melt, drip, or support combustion when exposed to extreme heat.

All-Weather Protection: Waterproof Breathable Membranes

To protect against wind and rain without trapping sweat, military outerwear utilizes sophisticated laminates. These fabrics, such as Gore-Tex®, bond a waterproof but breathable membrane to a durable outer face fabric, creating a composite material that keeps the elements out while allowing moisture vapor to escape.

Understanding the Trade-offs

No single fabric can do everything perfectly. The selection of a material always involves balancing competing priorities.

Durability vs. Weight and Flexibility

A thicker, heavier nylon fabric (measured in denier) offers superior abrasion resistance but comes at the cost of increased weight and reduced flexibility. Lighter denier fabrics are more comfortable but may not withstand the same level of abuse.

Protection vs. Comfort

Specialized protective fabrics often compromise on comfort. Ballistic vests made of Kevlar® can be heavy and hot, while flame-retardant Nomex® fabrics do not always offer the same breathability as standard nylon/cotton blends.

Cost and Complexity

High-performance textiles are expensive. The complex chemistry and manufacturing processes required for aramid fibers and waterproof-breathable membranes make them significantly more costly than conventional nylon, influencing their application and distribution.

Matching the Fabric to the Mission

The right choice is dictated entirely by the primary operational requirement.

- If your primary focus is load-bearing equipment (packs, vests, pouches): High-tenacity nylon is the standard due to its unmatched abrasion and tear resistance.

- If your primary focus is ballistic protection (body armor): Aramid fibers are non-negotiable for their ability to stop projectiles.

- If your primary focus is protection from fire and flash events: Meta-aramid fabrics are essential for pilots, combat vehicle crews, and special operations forces.

- If your primary focus is all-weather environmental defense: Waterproof-breathable laminates are critical for keeping personnel dry and effective in inclement conditions.

Ultimately, modern military performance is intrinsically linked to the advanced materials science woven into every piece of gear.

Summary Table:

| Fabric Type | Key Properties | Primary Military Applications |

|---|---|---|

| High-Tenacity Nylon (e.g., CORDURA®) | Extreme abrasion resistance, lightweight, fast-drying | Load-bearing equipment (packs, vests, pouches) |

| Aramid Fibers (e.g., Kevlar®) | High ballistic resistance, energy absorption | Body armor, fragmentation protection |

| Meta-Aramid Fibers (e.g., Nomex®) | Inherent flame resistance, does not melt or drip | Gear for pilots, vehicle crews, special ops |

| Waterproof-Breathable Membranes (e.g., Gore-Tex®) | Protection from wind/rain, moisture vapor escape | All-weather outerwear, environmental defense |

Need High-Performance Military Footwear or Gear? Partner with 3515.

As a large-scale manufacturer, 3515 produces a comprehensive range of durable and tactical footwear for distributors, brand owners, and bulk clients. Our production capabilities encompass all types of military-grade boots and shoes, engineered to meet the demanding conditions outlined above.

Let us help you equip your personnel with reliable, mission-ready footwear. Contact our expert team today to discuss your specific requirements and manufacturing solutions.

Visual Guide

Related Products

- Wholesale Lightweight Tactical Boots with Dial Closure OEM & Bulk Orders

- Safety Footwear Wholesale Manufacturer for Custom OEM/ODM Production

- Custom OEM Training Shoes Wholesale Manufacturer Durable & Breathable

- Wholesale Safety Footwear Manufacturer for Bulk & Custom OEM Orders

- Premium Wholesale Waterproof Safety Boots High Performance Protection for Industrial Markets

People Also Ask

- What are the different types of tactical boots? Choose the Right Boot for Your Mission

- What are the key components of a tactical boot? A Guide to Performance & Durability

- What makes traction and stability important in tactical boots? Essential for Safety & Performance

- Why is proper fit and comfort essential in tactical boots? Maximize Performance & Safety

- How should one choose the right size for tactical shoes? A Precision Fit Guide for Professionals