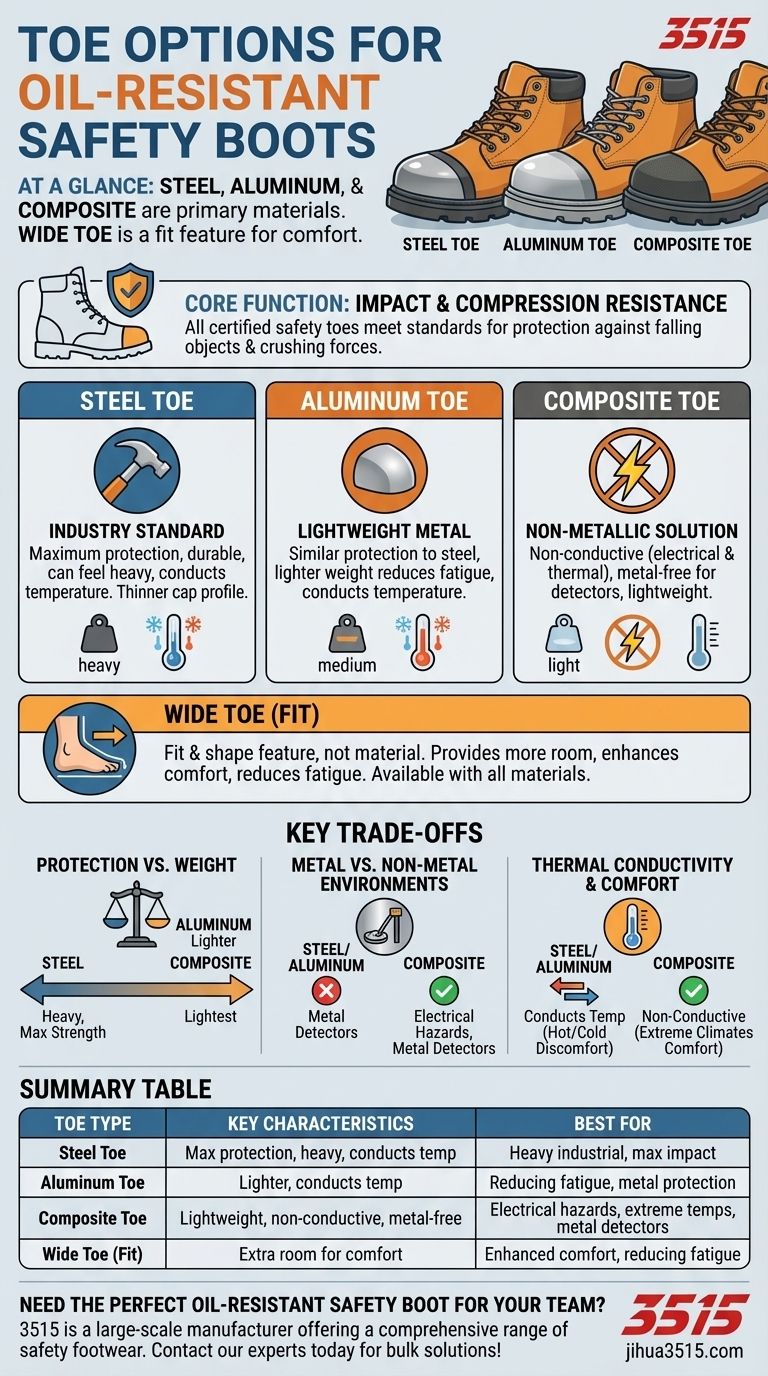

At a glance, the primary toe options available for oil-resistant safety boots are steel, aluminum, and composite. Many boots also offer a "wide toe" fit, which is a sizing feature for comfort rather than a distinct material type. Each material provides certified protection but offers different trade-offs in terms of weight, thermal conductivity, and interaction with electrical hazards.

The choice of a safety toe is not about finding the "best" material, but about matching the specific properties of steel, aluminum, or composite to the unique demands of your work environment and personal comfort needs.

The Core Function: Impact and Compression Resistance

Before comparing materials, it's crucial to understand that all certified safety toes—regardless of material—are designed to meet specific safety standards for impact and compression. This ensures a fundamental level of protection against falling objects and crushing forces.

The Role of Certification

All legitimate safety footwear is rated to protect against specific hazards. The primary function of the protective toe cap is to shield your feet from injury. The material used is simply the medium through which that protection is delivered.

Analyzing the Primary Safety Toe Materials

The distinction between toe types comes down to the material used in the protective cap. Each has inherent strengths and weaknesses that make it suitable for different applications.

Steel Toes: The Industry Standard

Steel is the traditional choice for safety toes, known for providing the highest level of protection against impact and compression. Modern steel toes are also treated to be non-corrosive, ensuring durability.

Because of its strength, a steel toe cap can be made thinner than other materials while still meeting safety standards. This can result in a less bulky, more streamlined boot profile.

Aluminum Toes: The Lightweight Metal Alternative

Aluminum toes offer a similar level of puncture, impact, and compression resistance as steel but at a significantly lighter weight. This can reduce foot fatigue over a long workday.

The primary benefit is this weight reduction, making them an excellent choice for workers who need robust metal protection without the heft of traditional steel.

Composite Toes: The Non-Metallic Solution

Composite toes are made from non-metal materials like Kevlar, carbon fiber, or plastic. Their key advantage is that they do not conduct electricity, making them ideal for electricians or workers in environments with electrical hazards.

They also don't conduct heat or cold, which provides greater comfort in extreme temperature environments. Since they contain no metal, they are also useful for workers who must pass through metal detectors.

Understanding the "Wide Toe" Option

The term "wide toe" is often listed alongside material types, but it refers to the fit and shape of the toe box, not the material itself.

Why Fit Is a Safety Feature

A boot with a wide toe box provides more room, preventing toes from being cramped. This enhances all-day comfort, reduces fatigue, and can prevent foot problems, making it a critical consideration for anyone who spends long hours on their feet. You can find wide-fit options in steel, aluminum, and composite toe boots.

Key Trade-offs When Choosing Your Toe Type

Objectively weighing the pros and cons of each material is the best way to select the right boot for your specific needs.

Protection vs. Weight

While all certified toes are protective, steel offers the classic benchmark for strength. However, this comes with added weight. Both aluminum and composite toes offer significant weight savings, which can be a decisive factor in reducing fatigue.

Metal vs. Non-Metal Environments

If your work involves potential electrical hazards or requires passing through metal detectors, a composite toe is the only logical choice. For all other environments, metal toes (steel or aluminum) are perfectly suitable.

Thermal Conductivity and Comfort

In very cold or hot working conditions, metal toes can transfer the ambient temperature to your feet, causing discomfort. Composite toes do not conduct temperature, making them a far more comfortable option in extreme climates.

Making the Right Choice for Your Job

Your final decision should be guided by the specific hazards and conditions of your workplace.

- If your primary focus is maximum impact resistance in a heavy industrial setting: A traditional steel toe provides proven, time-tested protection.

- If your primary focus is working around electrical hazards or metal detectors: A composite toe is essential for safety and convenience.

- If your primary focus is reducing fatigue from walking or standing all day: An aluminum or composite toe will provide certified protection at a much lower weight.

- If your primary focus is comfort in extreme hot or cold climates: A composite toe is the superior choice for thermal insulation.

Ultimately, selecting the correct safety toe is a critical step in ensuring both your safety and your comfort on the job.

Summary Table:

| Toe Type | Key Characteristics | Best For |

|---|---|---|

| Steel Toe | Maximum protection, durable, can feel heavy, conducts temperature | Heavy industrial settings, maximum impact resistance |

| Aluminum Toe | Lighter than steel, similar protection to steel, conducts temperature | Reducing fatigue while maintaining metal protection |

| Composite Toe | Lightweight, non-conductive (electrically and thermally), metal-free | Electrical hazards, extreme temperatures, passing through metal detectors |

| Wide Toe (Fit) | Extra room in toe box for comfort; available with all material types | Enhanced comfort, reducing foot fatigue, accommodating wider feet |

Need the Perfect Oil-Resistant Safety Boot for Your Team?

As a large-scale manufacturer, 3515 produces a comprehensive range of safety footwear for distributors, brand owners, and bulk clients. Our production capabilities encompass all types of oil-resistant boots with steel, aluminum, and composite toes, ensuring you get the right combination of safety, comfort, and durability for your specific work environment.

Contact our experts today to discuss your requirements and get a customized solution!

Visual Guide

Related Products

- Safety Footwear Wholesale Manufacturer for Custom OEM/ODM Production

- Premium Flame-Retardant Waterproof Safety Boots and Shoes

- Wholesale Safety Footwear Manufacturer for Bulk & Custom OEM Orders

- Wholesale Customizable Safety Boots Durable & Protective Footwear Manufacturing

- Custom Wholesale Leather Safety Boots Direct Factory Manufacturing

People Also Ask

- Which type of safety shoe is better for passing through metal detectors? Choose a 100% Non-Metallic Boot

- Why are metric foot measurement tools indispensable? Achieve Perfect Fit and Optimized Inventory for Protective Shoes

- How is the sole attached to the upper in safety shoes manufacturing? Choose the Right Bond for Durability

- Why are safety shoes important for preventing slips and falls? The Science of Slip-Resistant Soles

- What is a nano-toe? Lighter, Thinner Safety Footwear for Maximum Comfort

- Why is Human-Centred Design (HCD) essential for safety shoes? Boost Performance and Comfort in High-Stakes Environments

- How are intelligent pressure insoles used in functional footwear? Optimize Safety Shoes & Tactical Boots with Data

- How does physical conditioning assist tactical personnel in adapting to heavy safety shoes and boots?