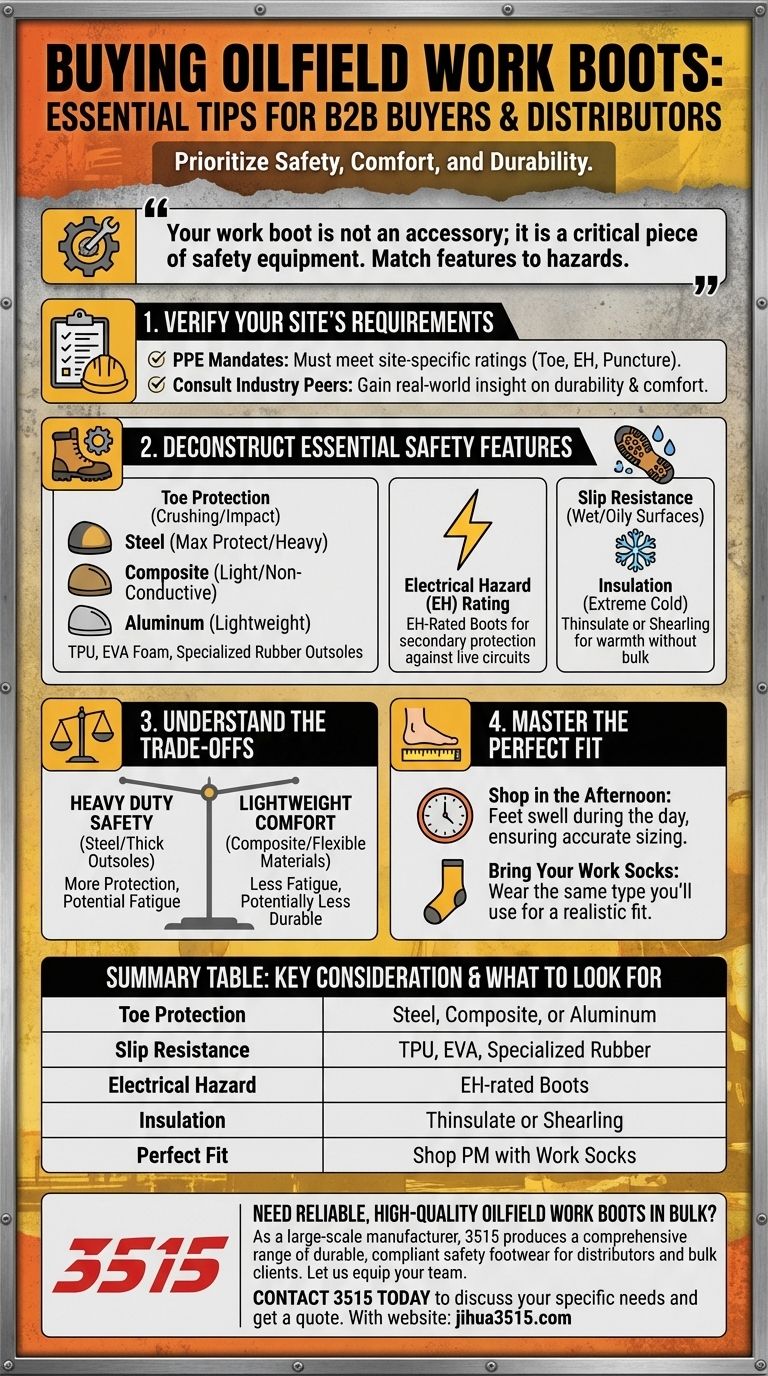

To buy the right oilfield work boots, you must first identify the specific Personal Protective Equipment (PPE) required for your job site. Once you know the non-negotiable safety standards, focus on features like slip-resistant outsoles, the correct toe protection, and a comfortable, supportive midsole. Always shop for boots in the afternoon with your typical work socks to ensure a true and accurate fit.

Your work boot is not an accessory; it is a critical piece of safety equipment. The primary goal is to match the boot's specific protective features directly to the known hazards of your work environment, from impact risks to slippery surfaces.

First, Verify Your Site's Requirements

Before you consider any brand or style, you must start with your employer's safety standards. This is the foundation of your decision and is not negotiable.

The Role of PPE Mandates

Every job site has a specific list of required PPE. Your boots must meet these minimum standards for you to be allowed on site. This often includes specific ratings for toe protection, electrical hazards, and puncture resistance.

Consult Industry Peers

Talk to experienced colleagues about what brands and models have worked well for them. They can provide invaluable, real-world insight into a boot's durability and comfort over long shifts in your specific conditions.

Deconstructing the Essential Safety Features

Understanding the technology and materials in a work boot allows you to make an informed choice beyond just meeting a compliance checklist.

Toe Protection: Steel, Composite, or Aluminum?

The toe cap is your primary defense against crushing and impact injuries. Steel toes offer maximum protection but can be heavy and conduct cold. Composite toes are lighter, don't conduct electricity or temperature, but can be bulkier. Aluminum toes provide a lightweight alternative to steel.

Slip Resistance: The Critical Role of the Outsole

Slips, trips, and falls are a leading cause of injury. Look for outsoles made from high-traction materials like Thermoplastic Polyurethane (TPU), EVA foam, or specialized rubber compounds designed for oily and wet surfaces.

Electrical Hazard (EH) Rating

If you work near potential electrical conductors, an EH-rated boot is essential. These boots are constructed to provide a secondary source of protection against accidental contact with live electrical circuits.

Insulation for Extreme Temperatures

For work in cold climates, proper insulation is crucial for both comfort and safety. Materials like Thinsulate provide significant warmth without excessive bulk, while natural shearling linings can also be effective.

Understanding the Trade-offs

Choosing the perfect boot involves balancing competing factors. A boot that excels in one area may have drawbacks in another.

Protection vs. Weight

Heavily protected boots, such as those with steel toes and thick outsoles, offer superior safety but can lead to fatigue over a 12-hour shift. Lighter composite materials can reduce this strain but may be less durable in the most extreme conditions.

Durability vs. Comfort

The most rugged, durable materials may require a significant "break-in" period to become comfortable. More flexible, comfortable boots might not withstand the constant abrasion and chemical exposure of an oilfield environment for as long.

Mastering the Perfect Fit

A poorly fitting boot, no matter how safe, can cause pain, blisters, and long-term foot problems, ultimately becoming a distraction and a safety risk itself.

Shop in the Afternoon

Your feet naturally swell throughout the day. Trying on boots in the afternoon or evening ensures you are fitting them to your feet at their largest size, preventing a fit that becomes too tight mid-shift.

Always Bring Your Work Socks

The thickness of your socks can dramatically alter how a boot fits. Always use the same type of sock you wear to work when trying on new boots to get a realistic sense of volume and space.

Making the Right Choice for Your Role

Use your specific job hazards and priorities to guide your final selection.

- If your primary focus is maximum impact protection: A steel-toe boot remains the gold standard for resisting crushing forces.

- If you work in extreme cold: Prioritize a boot with a high rating of Thinsulate insulation and a composite toe to avoid cold transfer.

- If you face consistently slick, oily, or wet surfaces: Scrutinize the outsole material and tread pattern, specifically seeking boots rated for high slip resistance.

- If you work long shifts on your feet: Pay extra attention to a boot with excellent shock absorption in the midsole to reduce fatigue and joint stress.

Investing the time to choose the correct boot is a direct investment in your daily safety and well-being on the job.

Summary Table:

| Key Consideration | What to Look For |

|---|---|

| Toe Protection | Steel (max protection), Composite (lightweight, non-conductive), or Aluminum (lightweight) |

| Slip Resistance | TPU, EVA foam, or specialized rubber outsoles for oily/wet surfaces |

| Electrical Hazard | EH-rated boots for protection against live circuits |

| Insulation | Thinsulate or shearling linings for work in extreme cold |

| Perfect Fit | Shop in the afternoon with your work socks for an accurate fit |

Need Reliable, High-Quality Oilfield Work Boots in Bulk?

As a large-scale manufacturer, 3515 produces a comprehensive range of safety footwear designed to meet the toughest demands of the oilfield. We provide durable, compliant boots with the right safety features—from steel toes to EH ratings—for distributors, brand owners, and bulk clients.

Let us help you equip your team with footwear that protects and performs. Contact 3515 today to discuss your specific needs and get a quote.

Visual Guide

Related Products

- Wholesale Safety Boots Manufacturer for Custom & Private Label Orders

- Premium High-Cut Waterproof Safety Boots Manufacturing & Wholesale Solutions

- Premium Wholesale Waterproof Safety Boots High Performance Protection for Industrial Markets

- Custom Wholesale Leather Safety Boots Direct Factory Manufacturing

- Premium Wholesale Wheat Nubuck Safety Boot with Rapid Lacing System

People Also Ask

- What are the different types of firefighter boots and their features? Essential Guide for Safety & Performance

- What precautions should be taken when waterproofing boots? Protect Your Investment and Stay Safe

- What product is recommended to protect leather boots from water saturation? Use a Wax-Based Conditioner

- What should be considered when sizing and fitting engineer boots? Master the Laceless Fit for Maximum Comfort

- Why are lightweight work boots beneficial? Boost Mobility & Reduce Fatigue

- What safety features are integrated into comfortable work boots? Get Certified Protection Without Sacrificing Comfort

- What primary protective functions do professional safety boots provide in urban solid waste recovery and waste picking processes? Discover Dual-Layer Protection.

- What safety features should hazard workers look for in lace-up work boots? A Guide to Certified Protection