In safety boot construction, textiles and synthetic materials are not just alternatives to leather; they are essential components engineered for specific functions. Materials like nylon provide lightweight durability and abrasion resistance for the upper, polyester linings wick away moisture for comfort, while polyurethane and rubber compounds are used in soles to balance grip, weight, and longevity.

The modern safety boot is best understood as an integrated system of materials. The choice is rarely about a single material but about finding the right combination of leather, textiles, and composites to deliver a specific balance of protection, durability, and user comfort for the intended environment.

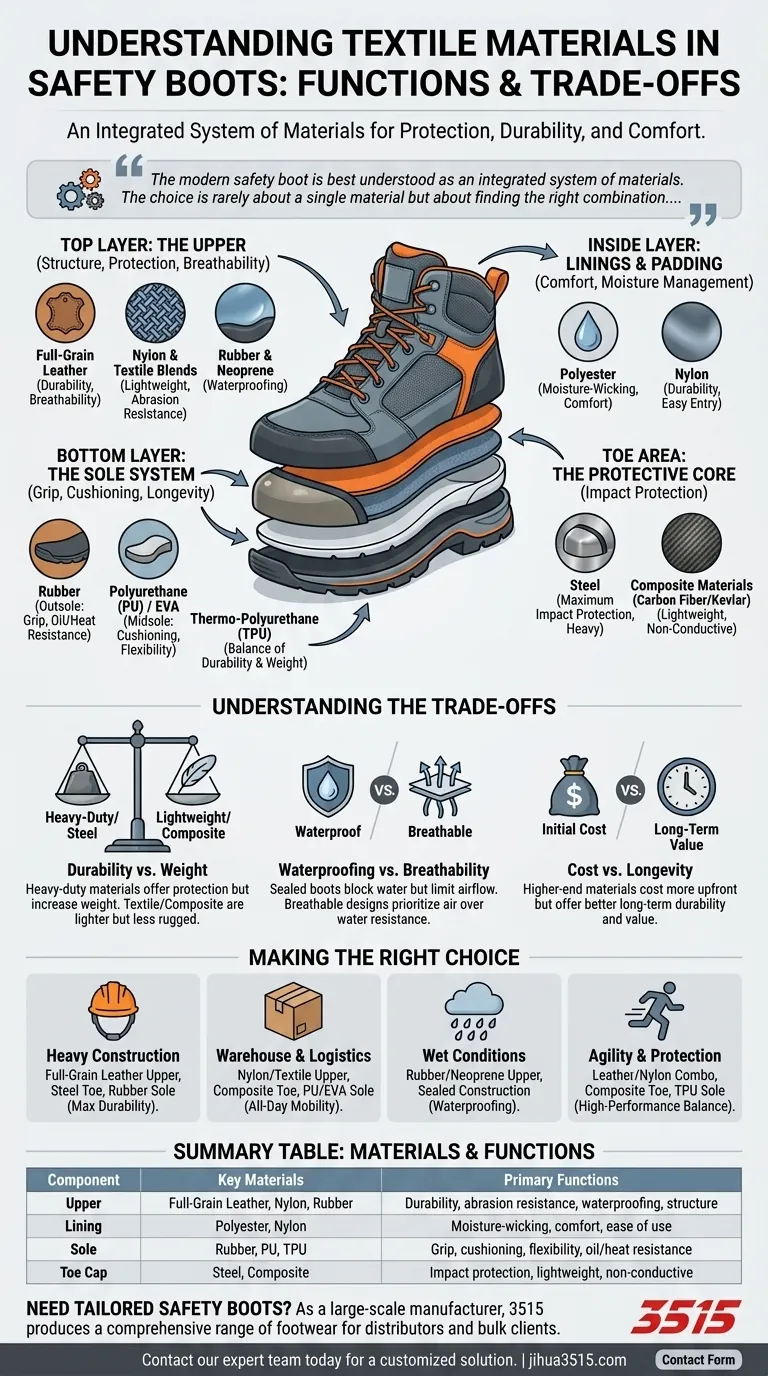

Deconstructing the Modern Safety Boot

A safety boot's performance is determined by the distinct materials used in each of its core components. Each material is selected to solve a specific problem, from external impacts to internal moisture.

The Upper: Your First Line of Defense

The upper is the main body of the boot, responsible for structure, environmental protection, and breathability.

- Full-Grain Leather: This is the highest quality leather, known for its exceptional durability and natural breathability. It provides excellent protection against abrasions.

- Nylon & Textile Blends: These synthetics are often integrated into uppers to reduce weight and increase flexibility. Nylon is highly valued for its resistance to tearing and abrasion.

- Rubber & Neoprene: When waterproofing is the primary requirement, these materials are used. They form an impermeable barrier against liquids, ideal for wet working conditions.

Linings and Padding: The Comfort Layer

The interior materials directly impact all-day wearability and foot health.

- Polyester: This common lining material is lightweight and excels at wicking moisture away from the skin, which helps keep feet dry and comfortable.

- Nylon: Used in linings, nylon adds a durable, smooth surface that resists wear from the inside and makes the boot easier to slide on and off.

The Sole System: Foundation of Performance

The sole is often a multi-layered system, with different materials used for the outsole (contact with the ground) and midsole (cushioning).

- Rubber: The traditional choice for outsoles, rubber offers superior grip and high resistance to oil, abrasion, and heat.

- Polyurethane (PU): A lighter-weight alternative to rubber, PU provides excellent cushioning and flexibility, reducing foot fatigue.

- Thermo-Polyurethane (TPU): TPU is more durable and abrasion-resistant than PU but lighter than rubber, offering a high-performance balance between the two.

- Ethylene-Vinyl Acetate (EVA): Typically found in the midsole, EVA is a foam-like material that provides lightweight shock absorption and comfort, similar to what is used in athletic footwear.

The Protective Core: Toe Caps and Plates

This is the non-negotiable safety component, defined by strict standards.

- Steel: The classic material for toe caps, steel offers maximum impact protection. Its primary downside is its significant weight.

- Composite Materials: Made from non-metal materials like carbon fiber, Kevlar, or plastic, composite toes are significantly lighter than steel. They still meet safety standards and won't conduct electricity or cold.

Understanding the Trade-offs

Choosing the right safety boot involves balancing competing factors. No single material is perfect for every application.

Durability vs. Weight

Heavy-duty materials like full-grain leather and steel offer unmatched protection and longevity but result in a heavier boot. Conversely, boots with textile uppers and composite toes are far lighter and more agile but may not withstand the same level of extreme abuse.

Waterproofing vs. Breathability

A fully waterproof boot using rubber or a sealed membrane is essential for wet environments, but it inherently limits breathability. In hot, dry conditions, this can lead to excessive sweat and discomfort. More breathable leather and nylon-mesh designs prioritize airflow at the expense of water resistance.

Cost vs. Longevity

Higher-end materials like full-grain leather and TPU soles typically increase the initial cost of a boot. However, their superior durability often results in a longer service life, providing better long-term value compared to less expensive boots made from split leather or basic PU.

Making the Right Choice for Your Goal

Select your boot based on the primary demands of your workday.

- If your primary focus is maximum durability for heavy construction: Prioritize a boot with a full-grain leather upper, a steel toe, and a solid rubber outsole.

- If your primary focus is all-day mobility in a warehouse or logistics role: Look for a lightweight boot with a composite toe and a flexible nylon/textile upper on a PU or EVA sole system.

- If your primary focus is working in consistently wet conditions: Choose a boot with a rubber or neoprene upper and a sealed, waterproof construction.

- If your primary focus is a balance of protection and athletic agility: A boot with a composite toe, a combination leather/nylon upper, and a TPU outsole offers a modern, high-performance solution.

Understanding these materials transforms your choice from a guess into a calculated decision for your personal safety and performance.

Summary Table:

| Component | Key Materials | Primary Functions |

|---|---|---|

| Upper | Full-Grain Leather, Nylon, Rubber | Durability, abrasion resistance, waterproofing, structure |

| Lining | Polyester, Nylon | Moisture-wicking, comfort, ease of use |

| Sole | Rubber, Polyurethane (PU), TPU | Grip, cushioning, flexibility, oil/heat resistance |

| Toe Cap | Steel, Composite (Carbon Fiber, Kevlar) | Impact protection, lightweight, non-conductive |

Need Safety Boots Tailored to Your Specific Needs?

As a large-scale manufacturer, 3515 produces a comprehensive range of footwear for distributors, brand owners, and bulk clients. Our production capabilities encompass all types of safety shoes and boots, engineered with the precise material combinations detailed above to meet your exact requirements for protection, durability, and comfort.

Let us help you equip your workforce with the right footwear. Contact our expert team today to discuss your project and receive a customized solution.

Visual Guide

Related Products

- Wholesale Durable Safety Boots Manufacturer Customizable Steel Toe Work Boots

- Wholesale Safety Boots Manufacturer for Custom & Private Label Orders

- Premium Grain Leather Safety Boots for Bulk Supply

- Customizable Anti-Smash Safety Boots for Wholesale & Private Label Manufacturing

- Durable Steel Toe Safety Boots Wholesale & Custom Manufacturing

People Also Ask

- What should someone do if they are unsure whether their injury requires a walking boot? Seek Expert Medical Advice

- What are the differences between steel toe, composite toe, and alloy toe Wellington boots? Choose the Right Safety Toe for Your Job

- How do professional construction boots improve operational efficiency? Boost Site Productivity with Advanced Footwear

- When should you seek immediate medical care while wearing a walking boot? Recognize Critical Warning Signs

- Why is manufacturer diversity and inclusion important in work boot design? For Superior Fit, Safety & Comfort