In truly waterproof boots, you should look for seams that are sealed, taped, or welded. Because every stitch creates a potential entry point for water, the best designs either minimize stitching entirely or render the stitch holes irrelevant by sealing them with a waterproof barrier. This construction is far more critical than the appearance of the external stitching itself.

The fundamental challenge is that the very act of stitching pokes holes in a waterproof material. Therefore, your evaluation shouldn't just be of the seam's strength, but of the technology used to make those holes completely impervious to water.

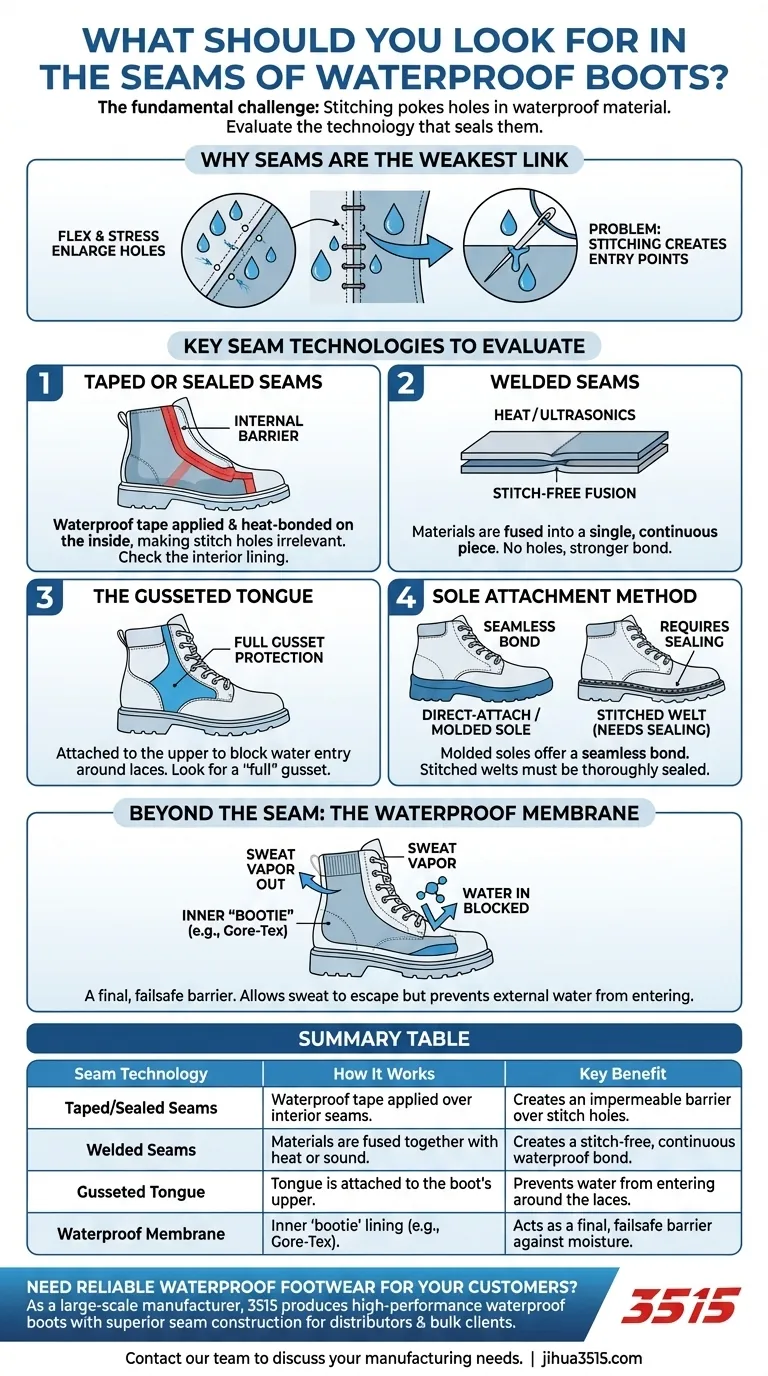

Why Seams Are the Weakest Link

The integrity of a waterproof boot is not determined by its primary material alone, but by its points of assembly. Seams are, by definition, the most vulnerable areas.

The Problem with Stitching

Every time a needle passes through a material like leather or nylon, it creates a tiny hole. While thread fills this hole, it doesn't create a permanent, watertight seal.

Under pressure or when submerged, water can be forced through these microscopic gaps, leading to a slow leak that eventually soaks your socks and feet.

The Impact of Flex and Stress

Your feet flex thousands of time a day. This motion puts constant stress on the boot's seams, particularly around the forefoot and where the upper connects to the sole.

Over time, this stress can slightly enlarge the stitch holes or wear down any sealant, compromising the boot's water resistance.

Key Seam Technologies to Evaluate

A truly waterproof boot uses specific construction methods to overcome the inherent weakness of a standard seam. Here is what to look for.

Taped or Sealed Seams

This is the gold standard for high-performance waterproof footwear. After the boot is stitched together, a layer of waterproof tape is applied over the seams on the inside of the boot and bonded with heat.

This creates an impermeable barrier, effectively making the stitch holes irrelevant. You can often see this taping by inspecting the boot's interior lining.

Welded Seams

Found most often on boots made from synthetic materials like PVC or rubber, welded seams use heat or ultrasonic vibrations to fuse two pieces of material together.

This process creates a single, continuous piece of material with no holes, offering a completely waterproof bond that is often stronger than the material itself.

The Gusseted Tongue

A common failure point is the tongue, where water can easily splash in around the laces. A gusseted tongue is attached to the boot's upper along the sides, creating a continuous waterproof barrier.

Always check to see how high the gusset extends. A "full" gusset that goes nearly to the top of the boot offers significantly more protection than a partial one.

Sole Attachment Method

The seam connecting the boot's upper to the sole is the most critical.

- Direct-Attach or Molded Soles: In this construction, the sole is molded directly onto the upper, creating a seamless, waterproof bond that is highly reliable.

- Stitched Soles (Welts): Traditional construction methods like a Goodyear welt involve stitching the sole to the upper. For these to be waterproof, they must use waterproofed thread and be thoroughly sealed at the factory.

Beyond the Seam: The Waterproof Membrane

Modern waterproof boots rarely rely on sealed seams alone. They employ a system of defense, with a waterproof membrane acting as the final, guaranteed barrier.

The Inner "Bootie"

High-quality boots from brands like Gore-Tex feature a full waterproof and breathable membrane, shaped like a sock, built into the boot's lining. This "bootie" is a complete, seam-sealed layer.

This membrane allows sweat vapor to escape but prevents larger water molecules from entering, keeping your feet dry from both the inside and the outside.

A System of Redundancy

Think of this as a two-layer defense. The boot's outer material and sealed seams are the first line, repelling the vast majority of water. The inner membrane is the failsafe, ensuring that any moisture that might eventually penetrate the outer layer never reaches your foot.

A boot with both a robust outer construction and a quality inner membrane offers the highest level of reliable waterproof performance.

Making the Right Choice for Your Goal

Your ideal boot depends on the balance of waterproofing, breathability, and durability you require.

- If your primary focus is absolute waterproofing for wet, muddy work: Choose boots with a molded, stitch-free construction, such as those made from high-quality rubber or PVC.

- If your primary focus is all-weather hiking or hunting: Look for boots with a reputable waterproof membrane (like Gore-Tex) combined with externally sealed or taped seams for maximum protection and breathability.

- If your primary focus is long-term durability in varied conditions: Select boots with a direct-attached sole or a properly sealed, welted construction, ensuring they also contain a waterproof inner membrane.

By understanding how a boot is constructed at its seams, you can confidently choose footwear that delivers on its promise to keep you dry.

Summary Table:

| Seam Technology | How It Works | Key Benefit |

|---|---|---|

| Taped/Sealed Seams | Waterproof tape applied over interior seams. | Creates an impermeable barrier over stitch holes. |

| Welded Seams | Materials are fused together with heat or sound. | Creates a stitch-free, continuous waterproof bond. |

| Gusseted Tongue | Tongue is attached to the boot's upper. | Prevents water from entering around the laces. |

| Waterproof Membrane | Inner 'bootie' (e.g., Gore-Tex) lining. | Acts as a final, failsafe barrier against moisture. |

Need Reliable Waterproof Footwear for Your Customers?

As a large-scale manufacturer, 3515 produces a comprehensive range of high-performance waterproof boots for distributors, brand owners, and bulk clients. Our production capabilities ensure superior construction with sealed seams, gusseted tongues, and integrated membranes for maximum durability and protection.

Let us help you equip your market with footwear that stands up to the toughest conditions. Contact our team today to discuss your manufacturing needs.

Visual Guide

Related Products

- Safety Footwear Wholesale Manufacturer for Custom OEM/ODM Production

- High Performance Fire-Retardant Waterproof Safety Boots

- Premium High-Cut Waterproof Safety Boots Manufacturing & Wholesale Solutions

- Wholesale Safety Footwear Manufacturer for Bulk & Custom OEM Orders

- Premium Flame-Retardant Waterproof Safety Boots and Shoes

People Also Ask

- Why is a high-intensity ultraviolet (UV) cabinet used to irradiate treated leather samples? Ensure Material Durability

- What are the advantages of using recycled nylon yarn from fishing nets? High-Performance Gear Meets Sustainability

- What is the impact of efficient courier services on footwear purchases? Elevate Your Brand's Logistics Strategy

- What are the benefits of wearing shoes indoors? A Guide to Support, Safety, and Hygiene

- Why is a high-precision tri-axial IMU essential for fall detection footwear? Enhance Safety with Advanced Motion Sensing

- What are the key anatomical differences between male and female feet? Find the Perfect Fit for Your Foot Shape

- Why is weight less of a concern for winter boots? Prioritizing Warmth & Safety Over Lightness

- What are the characteristics of minimalist footwear in biomechanics studies? Unlock the Power of Control Group Testing