To properly maintain your tactical boots, you must regularly inspect the three most common failure points: the soles, the seams and uppers, and the laces. A thorough inspection involves checking the soles for embedded objects and cracks, examining all stitching for signs of separation, and ensuring laces are free from frays or weak spots.

The goal of regular inspection is not just cleaning; it's preventative maintenance. Identifying a minor issue like a fraying stitch or a small sole puncture today prevents a critical gear failure when you need your boots the most.

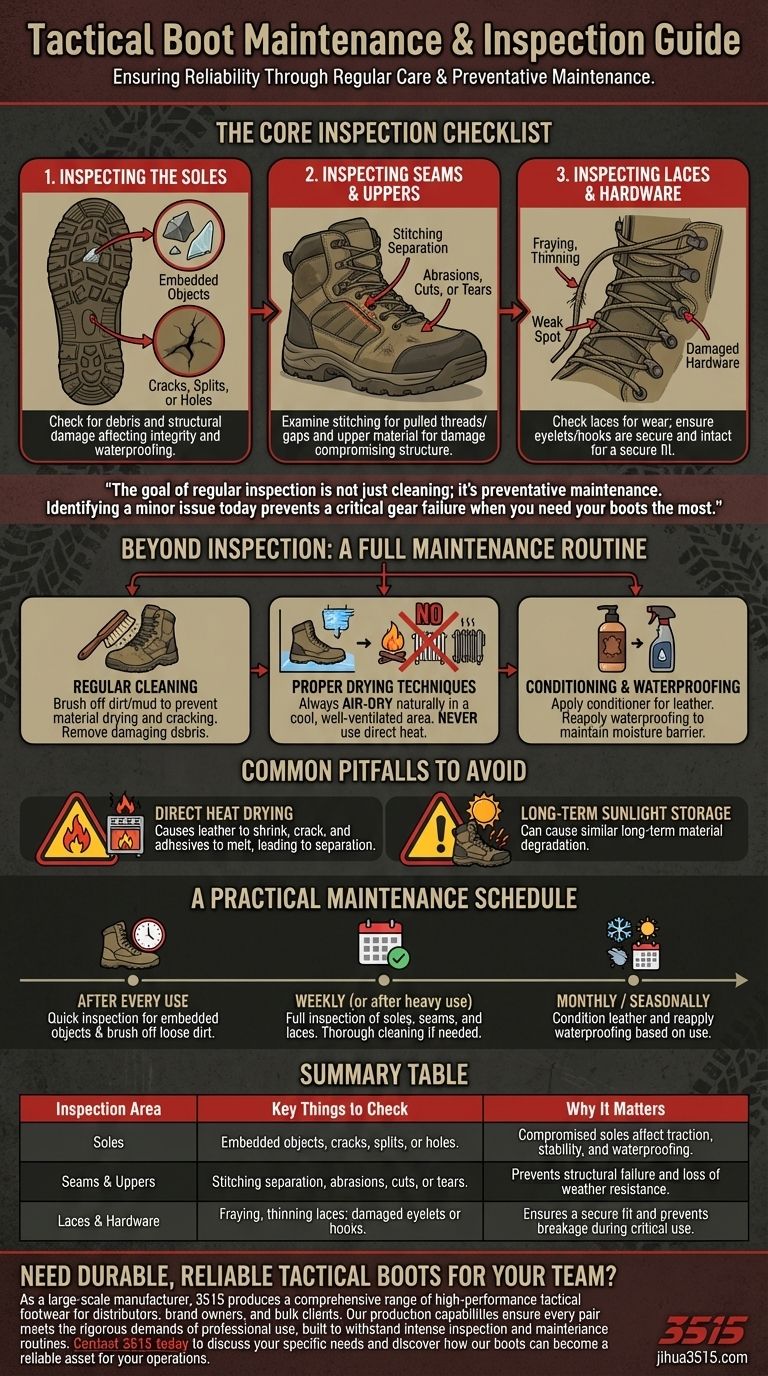

The Core Inspection Checklist

A systematic inspection ensures you don't miss early warning signs of degradation. This process should become a routine part of your gear maintenance, especially after heavy use.

Inspecting the Soles

The sole is your primary interface with the ground and your first line of defense.

Check for any embedded objects like sharp rocks, glass, or metal shards that could work their way through the material over time.

Look closely for any cracks, splits, or holes. These compromise the sole's integrity and waterproofing, and they can grow quickly if left unaddressed.

Inspecting Seams and Uppers

Seams are a common point of failure where different materials are joined.

Run your eyes along all stitching and seams, especially where the upper connects to the sole. Look for any pulled threads, separation, or gaps.

Examine the boot's upper material (leather or synthetic) for significant abrasions, cuts, or tears that could compromise its structure or weather resistance.

Inspecting Laces and Hardware

Laces are a high-wear item that is critical for a secure fit but often overlooked.

Check your laces for any fraying, thinning, or damage. A worn lace is likely to snap when you're tightening it before a mission or during movement.

Ensure all eyelets, hooks, and other hardware are secure and free from damage that could sever a lace.

Beyond Inspection: A Full Maintenance Routine

Inspection is just one piece of a comprehensive care strategy. True longevity comes from a consistent maintenance routine that protects the materials themselves.

The Importance of Regular Cleaning

Dirt and mud draw moisture out of leather, causing it to dry out and crack. Grime can also wear away at synthetic fibers and stitching.

Clean your boots regularly, even if it's just a quick brushing, to remove damaging debris.

Proper Drying Techniques

Improper drying can do more damage than weeks of hard use.

Always let your boots air-dry naturally in a cool, well-ventilated area. Never place them near direct heat sources like a campfire, radiator, or heater.

Conditioning and Waterproofing

These steps are vital for preserving the boot's materials and protective qualities.

For leather boots, apply a quality conditioner periodically to restore essential oils and prevent cracking.

Reapply waterproofing treatments as needed to maintain a barrier against moisture, which is crucial for both comfort and the health of the boot materials.

Common Pitfalls to Avoid

Avoiding common mistakes is as important as performing the right maintenance tasks. The most significant error is using direct heat for drying.

High heat can cause leather to shrink, crack, and become brittle. It can also melt adhesives used to bond the sole to the upper, leading to catastrophic separation. Storing boots in direct sunlight can cause similar long-term damage.

A Practical Maintenance Schedule

- After every use: Perform a quick inspection for embedded objects in the sole and brush off any loose dirt.

- Weekly (or after heavy use): Conduct the full inspection of soles, seams, and laces. Clean thoroughly if needed.

- Monthly/Seasonally: Condition leather and reapply waterproofing treatments, depending on your environment and frequency of use.

Your boots are a critical piece of equipment, and consistent care ensures they remain a reliable asset rather than a potential liability.

Summary Table:

| Inspection Area | Key Things to Check | Why It Matters |

|---|---|---|

| Soles | Embedded objects, cracks, splits, or holes. | Compromised soles affect traction, stability, and waterproofing. |

| Seams & Uppers | Stitching separation, abrasions, cuts, or tears. | Prevents structural failure and loss of weather resistance. |

| Laces & Hardware | Fraying, thinning laces; damaged eyelets or hooks. | Ensures a secure fit and prevents breakage during critical use. |

Need Durable, Reliable Tactical Boots for Your Team?

As a large-scale manufacturer, 3515 produces a comprehensive range of high-performance tactical footwear for distributors, brand owners, and bulk clients. Our production capabilities ensure every pair meets the rigorous demands of professional use, built to withstand intense inspection and maintenance routines.

Contact 3515 today to discuss your specific needs and discover how our boots can become a reliable asset for your operations.

Visual Guide

Related Products

- Wholesale Lightweight Tactical Boots with Dial Closure OEM & Bulk Orders

- Safety Footwear Wholesale Manufacturer for Custom OEM/ODM Production

- Custom OEM Training Shoes Wholesale Manufacturer Durable & Breathable

- Wholesale Safety Footwear Manufacturer for Bulk & Custom OEM Orders

- Premium Wholesale Waterproof Safety Boots High Performance Protection for Industrial Markets

People Also Ask

- What is the significance of using professional tactical boots for motion tracking? Ensure Data Precision & Stability

- What does the NON-MARKING feature in tactical work boots entail? Ensure Stealth and Cleanliness

- Can tactical boots be used for everyday wear? Discover Professional Durability & All-Day Comfort

- Why is it important to size up when choosing winter tactical boots? Unlock Maximum Warmth & Performance

- Why is slip resistance important in tactical boots? Ensure Mission-Critical Safety and Stability

- How do tactical work boots benefit professionals? Unlock Superior Protection & Performance

- How do tactical combat boots differ from standard tactical boots? A Guide to Choosing the Right Footwear for Your Mission

- What specific features are necessary for tactical boots used by emergency rescue personnel? Build Your Survival Gear