For a concrete worker, the ideal work boot must provide robust chemical resistance against the alkalinity of wet cement, an ASTM-rated safety toe for impact protection, and a highly durable, slip-resistant outsole. All-day comfort and support are equally critical, as the job demands long hours standing on hard, unforgiving surfaces.

The central challenge is that wet concrete is not just water and dirt; it's a chemically corrosive substance that will destroy standard work boots. Your primary goal must be to find a boot engineered to resist this chemical attack while providing the safety and comfort needed for a demanding physical job.

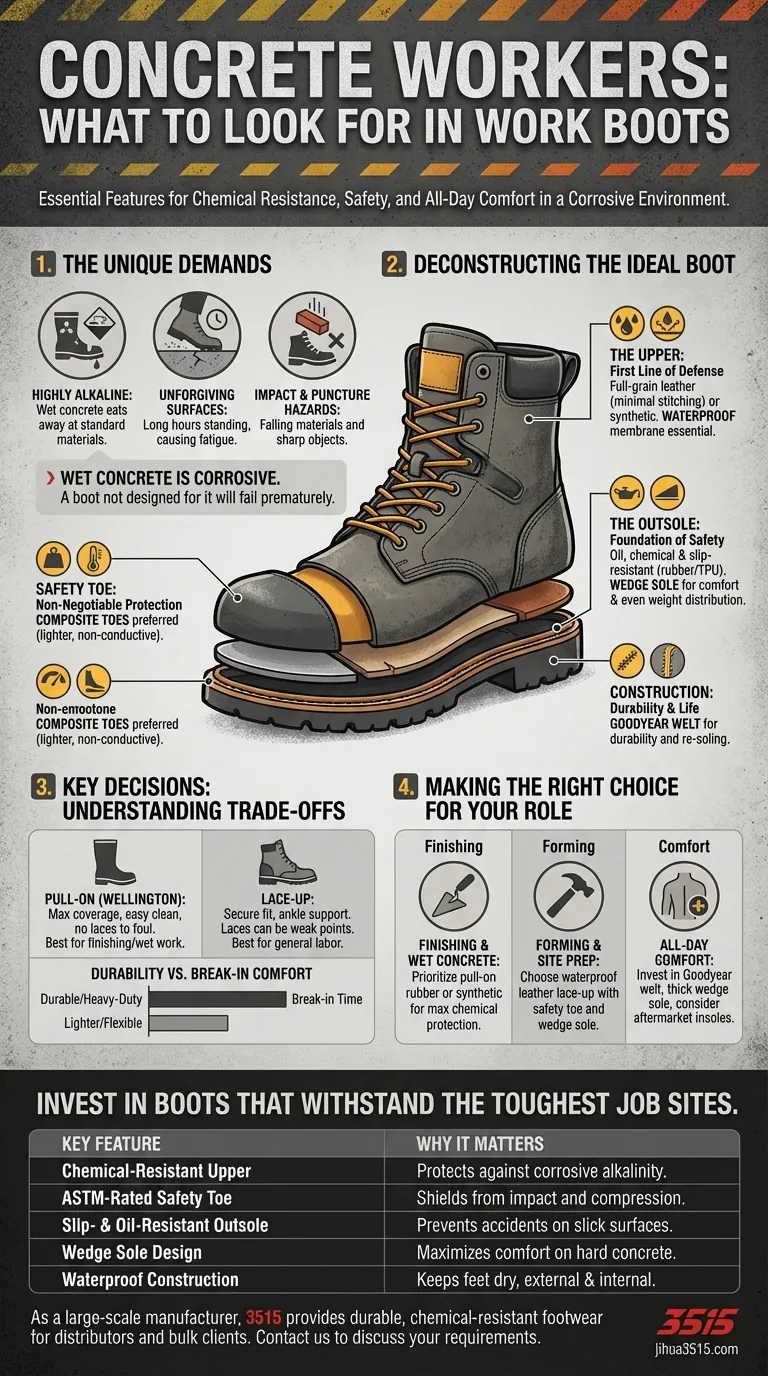

The Unique Demands of a Concrete Job Site

Working with concrete places a unique set of stresses on both your feet and your footwear. Understanding these challenges is the first step to choosing the right boot.

The Chemical Threat of Wet Concrete

Wet concrete is highly alkaline. This chemical composition actively breaks down and eats away at boot materials, especially low-quality leathers and stitching.

This corrosive nature is the single biggest factor that separates concrete work from other construction trades. A boot not designed for it will fail prematurely.

Unforgiving Surfaces and Long Hours

Concrete workers spend the majority of their day on their feet. You are either walking on uneven ground and rebar during a pour or standing on hard, finished concrete for hours.

This environment demands exceptional cushioning and support to prevent foot, knee, and back fatigue.

Impact and Puncture Hazards

A construction site is an unpredictable environment. The risk of heavy materials falling on your feet or stepping on sharp objects like rebar tie wires is constant.

Proper protection is not a recommendation; it is a fundamental requirement for your personal safety.

Deconstructing the Ideal Concrete Boot

A well-made boot is a system of components working together. For concrete work, you must scrutinize each part.

The Upper: Your First Line of Defense

The boot's upper is what faces the most direct contact with wet concrete. Look for full-grain leather with minimal stitching or high-quality synthetic materials.

Waterproof membranes are essential to keep your feet dry from both external moisture and sweat.

The Outsole: Foundation of Safety and Durability

The outsole must be made of a material, typically a high-grade rubber or thermoplastic polyurethane (TPU), that is oil-, chemical-, and slip-resistant.

Many professionals prefer a wedge sole. This design provides a flat, even surface that distributes your weight, maximizing comfort on hard, flat surfaces and preventing you from leaving marks in fresh concrete.

The Safety Toe: Non-Negotiable Protection

A safety toe is mandatory. You have two primary choices.

Composite toes are lighter than steel, do not conduct heat or cold, and still meet the same ASTM safety standards. They are often the preferred choice for comfort.

The Construction: How It's All Held Together

The way the sole is attached to the upper determines the boot's durability and water resistance. A Goodyear welt construction is a time-tested method that is extremely durable and allows the boot to be re-soled, extending its life.

Understanding the Trade-offs

There is no single "perfect" boot for every person and every job. You must balance competing priorities.

Pull-On vs. Lace-Up

Pull-on boots, often called Wellington boots, offer maximum coverage and have no laces that can get caked with concrete. This makes them easy to clean and highly resistant to chemical intrusion.

Lace-up boots provide a more secure, customized fit, which can increase ankle support and stability on uneven terrain. However, the laces and eyelets can be weak points for concrete to damage.

Durability vs. Break-In Comfort

The most durable, heavy-duty boots often require a significant break-in period. Lighter, more flexible boots might feel great out of the box but may not withstand the chemical abuse for as long.

Be prepared to invest time in breaking in a quality pair of leather boots for long-term performance.

Making the Right Choice for Your Role

Select your boot based on the specific tasks you perform most often.

- If your primary focus is finishing or working directly in wet concrete: Prioritize a pull-on rubber or specialized synthetic boot for maximum chemical protection and easy cleanup.

- If your primary focus is forming, general labor, or site prep: Choose a high-quality, waterproof leather boot with a safety toe and a slip-resistant wedge sole for a balance of durability, comfort, and safety.

- If your primary focus is all-day comfort for a bad back or knees: Invest in a boot with a proven Goodyear welt construction and a thick wedge sole, and consider adding aftermarket insoles for customized support.

Ultimately, choosing the right work boot is a crucial investment in your daily safety, comfort, and long-term health.

Summary Table:

| Key Feature | Why It Matters for Concrete Work |

|---|---|

| Chemical-Resistant Upper | Protects against the corrosive alkalinity of wet cement. |

| ASTM-Rated Safety Toe | Shields feet from impact and compression hazards on site. |

| Slip- & Oil-Resistant Outsole | Provides stability and prevents accidents on slick surfaces. |

| Wedge Sole Design | Maximizes comfort and weight distribution on hard, flat concrete. |

| Waterproof Construction | Keeps feet dry from external moisture and internal sweat. |

Invest in Boots That Withstand the Toughest Job Sites

As a concrete worker, your safety and comfort depend on the quality of your gear. At 3515, we are a large-scale manufacturer with the expertise to produce the exact boots you need. We offer a comprehensive range of durable, chemical-resistant footwear designed for the unique demands of distributors, brand owners, and bulk clients.

Let us help you equip your team with footwear that combines superior protection, lasting comfort, and exceptional value.

Contact 3515 today to discuss your work boot requirements and request a quote.

Visual Guide

Related Products

- Wholesale Safety Footwear Manufacturer for Bulk & Custom OEM Orders

- Safety Footwear Wholesale Manufacturer for Custom OEM/ODM Production

- Premium Flame-Retardant Waterproof Safety Boots and Shoes

- Premium Sport Style Safety Boots for Bulk Orders

- Advanced KPU Athletic Safety Shoe with Steel Toe Cap Anti-Slip Rotary Lacing System

People Also Ask

- What are the primary protective functions of safety shoes with steel toes in the automotive repair industry?

- How do safety shoes contribute to cost savings for companies? A Strategic Investment in Risk and Cost Management

- Why is manufacturer diversity and inclusion important in work boot design? For Superior Fit, Safety & Comfort

- What are the differences between steel toe, composite toe, and alloy toe Wellington boots? Choose the Right Safety Toe for Your Job

- What are the primary safety functions of safety boots with steel-toe designs? Essential Protection for Industry