A comprehensive foot safety program is a multi-faceted system designed to proactively prevent workplace injuries. Its essential components include a thorough hazard assessment followed by the selection of appropriate footwear, correct fit testing, employee training, and established protocols for maintenance and inspection.

An effective foot safety program is not a one-time purchase, but a continuous cycle. It begins with understanding the specific risks of your environment and extends through the entire lifecycle of the protective footwear, empowering employees to be active participants in their own safety.

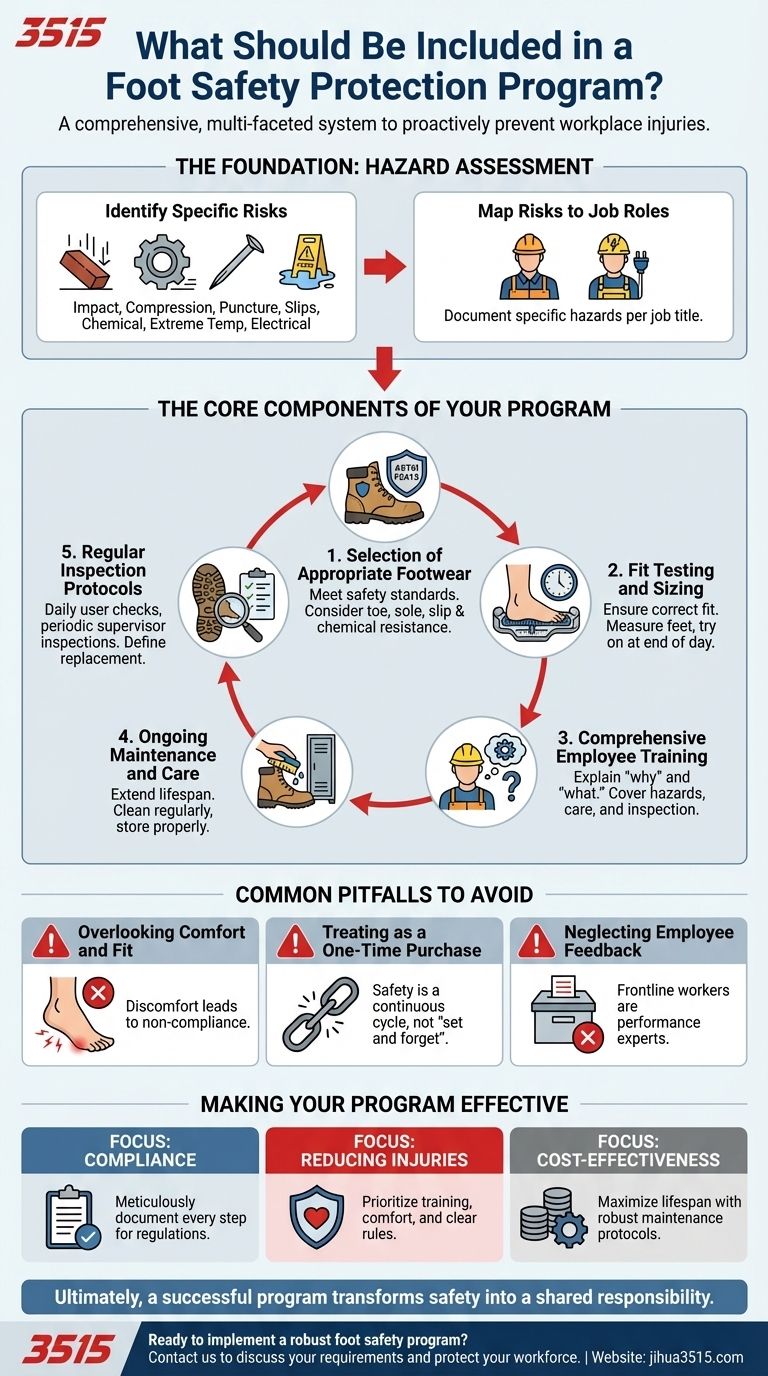

The Foundation: Hazard Assessment

Before selecting any footwear, you must first understand the environment. A formal hazard assessment is the non-negotiable starting point for any credible safety program.

Identify the Specific Risks

You must identify every potential threat to foot safety. This includes falling objects (impact), rolling equipment (compression), sharp objects on the ground (puncture), and slick surfaces (slips).

Other critical hazards include exposure to chemicals, extreme temperatures, and electrical currents.

Map Risks to Job Roles

Not every employee faces the same risks. A warehouse worker may need impact and puncture protection, while an electrician requires footwear with electrical hazard (EH) resistance.

Document the specific hazards associated with each job title to create a clear profile for the type of protection needed.

The Core Components of Your Program

With a clear understanding of the risks, you can implement the five core pillars of the protection program.

1. Selection of Appropriate Footwear

The results of your hazard assessment directly dictate footwear selection. Look for boots that meet or exceed relevant safety standards, such as ASTM F2413 in the United States.

Key features to consider include steel or composite safety toes for impact, puncture-resistant soles, slip-resistant outsoles, and material compositions designed for chemical or water resistance.

2. Fit Testing and Sizing

Protective footwear is only effective if it is worn correctly and consistently. An improper fit can cause blisters, pain, and fatigue, leading employees to avoid wearing their PPE.

Ensure employees are properly measured and have a chance to try on footwear, preferably at the end of the day when feet are slightly swollen. Encourage them to wear the same type of socks they would normally use for work.

3. Comprehensive Employee Training

Training transforms a safety mandate into a shared responsibility. Employees must understand the "why" behind the program, not just the "what."

Your training should cover the specific hazards their footwear protects against, the limitations of the protection, how to properly care for their boots, and how to inspect them for wear and tear.

4. Ongoing Maintenance and Care

Proper care extends the functional life of safety footwear. Instruct employees on how to clean and store their boots according to the manufacturer's guidelines.

Regular cleaning prevents the degradation of materials and allows for easier inspection of potential damage.

5. Regular Inspection Protocols

A clear inspection process is essential for identifying when footwear is no longer safe. This should be a two-level process.

Employees should perform a quick daily check for obvious damage. Supervisors or safety leads should conduct more formal periodic inspections, looking for issues like exposed safety toes, separated soles, or worn-out treads that reduce slip resistance. A clear policy must dictate when footwear is to be replaced.

Common Pitfalls to Avoid

Even well-intentioned programs can fail if they fall into common traps. Being aware of these pitfalls is critical for long-term success.

Overlooking Comfort and Fit

The single biggest reason for non-compliance is discomfort. If the provided footwear is painful or fits poorly, employees will be tempted to wear something else. Prioritizing comfort alongside safety features is essential for buy-in.

Treating the Program as a One-Time Purchase

Safety is not a "set it and forget it" task. Footwear wears out, job roles change, and new hazards can emerge. The program must be a continuous loop of assessment, implementation, and review.

Neglecting Employee Feedback

Your frontline workers are the ultimate experts on how the footwear performs in their daily tasks. Create a simple feedback channel for them to report issues with fit, comfort, or durability. This feedback is invaluable for improving your selection process over time.

Making Your Program Effective

Use these guidelines to tailor the program to your organization's primary goals.

- If your primary focus is compliance: Ensure every step, from the initial hazard assessment to individual training records, is meticulously documented to meet regulatory standards.

- If your primary focus is reducing injury rates: Prioritize employee buy-in through comprehensive training, offering comfortable footwear choices, and enforcing clear inspection and replacement rules.

- If your primary focus is cost-effectiveness: Implement a robust maintenance and inspection protocol to maximize the functional lifespan of footwear and prevent unnecessary premature replacements.

Ultimately, a successful foot protection program transforms safety from a top-down mandate into a shared responsibility.

Summary Table:

| Core Component | Key Action | Purpose |

|---|---|---|

| Hazard Assessment | Identify workplace risks (impact, puncture, slips) | Foundation for selecting the right protection |

| Footwear Selection | Choose boots meeting safety standards (e.g., ASTM F2413) | Directly address identified hazards |

| Fit Testing | Ensure proper sizing and comfort for each employee | Maximize compliance and effectiveness |

| Employee Training | Educate on hazards, boot care, and inspection | Empower employees and create shared responsibility |

| Maintenance & Inspection | Implement daily checks and periodic formal inspections | Ensure ongoing protection and identify replacement needs |

Ready to implement a robust foot safety program? As a large-scale manufacturer, 3515 produces a comprehensive range of safety footwear for distributors, brand owners, and bulk clients. Our production capabilities encompass all types of safety shoes and boots designed to meet the highest standards. We can provide the durable, comfortable, and compliant footwear your program needs. Contact us today to discuss your requirements and protect your workforce.

Visual Guide

Related Products

- Wholesale Customizable Safety Boots Durable & Protective Footwear Manufacturing

- Wholesale Premium Waterproof Nubuck Safety Shoes Boots

- Durable Leather Safety Boots for Wholesale & Custom OEM Manufacturing

- High Performance Fire-Retardant Waterproof Safety Boots

- Advanced KPU Athletic Safety Shoe with Steel Toe Cap Anti-Slip Rotary Lacing System

People Also Ask

- What is the most common shoe width for safety toe boots? The Critical Fit Guide for Comfort & Safety

- What are the requirements for EN ISO 20345 compliant safety shoes? A Guide to S1, S3 & S5 Ratings

- How can work shoes help manage plantar fasciitis? Alleviate Heel Pain & Improve Daily Comfort

- What is Goodman and Kruskal’s Gamma for Safety Shoe Analysis? Link Performance Ratings to Wear Frequency

- What is the ASTM F2413 Standard for protective toe boots? Ensure OSHA-Compliant Foot Safety

- How do ergonomic designs and industrial safety features in footwear improve health? Maximize Safety & Compliance

- What are the main categories used to classify work shoes? Find Your Perfect Safety Footwear

- What is the objective of incorporating QFD into technical safety shoes? Translate User Needs to Ensure Optimal Safety & Design