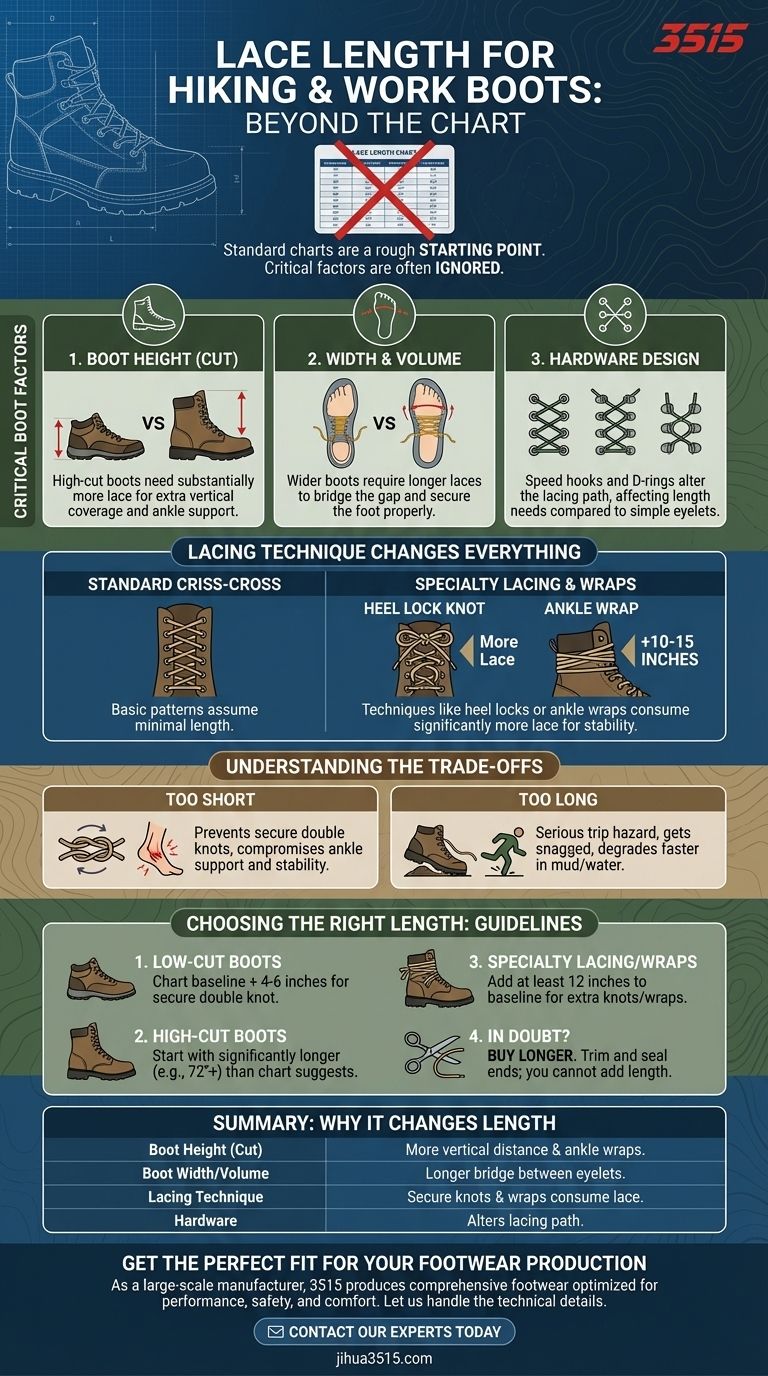

When using a lace length chart for hiking and work boots, you must treat it as a rough starting point, not a final rule. The critical factors the chart ignores are the boot's height (cut), its width, and the specific lacing techniques you use for a secure fit, all of which significantly alter the required lace length.

A standard chart is designed for casual shoes, not for technical footwear. For hiking and work boots, where a secure fit is critical for safety and stability, you must account for the boot's unique design and your personal lacing method to determine the correct length.

Beyond the Eyelet Count: Critical Boot Factors

A simple eyelet count is insufficient for determining lace length on specialized boots. The physical construction of the boot itself is the most important variable.

The Impact of Boot Height (Cut)

The most significant factor is the boot's cut. Low-cut day hiking boots may align with a chart, but high-cut backpacking or work boots require substantially longer laces to accommodate the extra vertical distance and potential ankle wraps.

Boot Width and Volume

The distance between the eyelets matters. A boot with a wider fit or more internal volume will require a longer lace to bridge the gap and secure your foot properly compared to a narrower boot with the same number of eyelets.

Eyelet and Hook Design

The type of hardware used influences the path of the lace. Boots often use a combination of traditional eyelets and speed hooks or D-rings near the top. Speed hooks can change the lacing angle and may require a slightly different length than a boot using only standard eyelets.

How Your Lacing Technique Changes Everything

How you lace your boots is just as important as the boots themselves. Charts assume a basic criss-cross pattern, but functional lacing for technical footwear is often more complex.

Standard Lacing vs. Specialty Knots

Techniques like a surgeon's knot or a heel lock are used to create a more secure, customized fit and prevent your foot from sliding. These methods consume more lace than a simple crossover pattern and must be factored in.

Lacing for Support and Comfort

Many hikers and workers wrap their laces around the boot's ankle collar for additional support. This technique uses a significant amount of extra lace—often 10-15 inches—that no standard chart will ever account for.

Understanding the Trade-offs

Choosing the wrong lace length for performance footwear isn't just an inconvenience; it can be a safety issue.

The Problem with Laces That Are Too Short

Laces that are too short prevent you from using secure double knots, which are essential on a trail or a job site. This can lead to laces coming undone at critical moments, compromising your ankle support and stability.

The Hazard of Laces That Are Too Long

Excessively long laces create a serious trip hazard. They can easily get snagged on roots, rocks, or machinery, leading to a fall. They also drag through mud, water, and dirt, causing them to degrade faster.

Choosing the Right Lace Length for Your Boots

Use your specific needs and equipment to make an informed decision. The best method is always to measure the laces that came with your boots, but if you're starting fresh, follow these guidelines.

- If you have standard, low-cut hiking or work boots: The chart is a reasonable starting point, but add 4-6 inches to ensure you have enough length for a secure double knot.

- If you have high-cut backpacking or heavy-duty work boots: Start with a length significantly longer than the chart suggests for that eyelet count; often 72 inches or more is a safe bet.

- If you use specialized lacing techniques or wrap your ankles: Add at least 12 inches to the baseline recommendation to accommodate the extra wraps and knots.

- If you are ever in doubt: Always buy laces that are longer than you think you need. You can easily trim excess length and seal the ends, but you can never add length to a lace that's too short.

Ultimately, your laces are a small but essential piece of gear that directly impacts your comfort and safety.

Summary Table:

| Factor | Why It Changes Lace Length |

|---|---|

| Boot Height (Cut) | Higher boots require more lace to cover the vertical distance and for ankle wraps. |

| Boot Width/Volume | Wider boots need longer laces to bridge the gap between eyelets for a secure fit. |

| Lacing Technique | Secure knots (e.g., heel lock) and ankle wraps consume significantly more lace. |

| Hardware (Hooks/Rings) | Speed hooks and D-rings alter the lacing path compared to standard eyelets. |

Get the Perfect Fit for Your Footwear Production

As a large-scale manufacturer, 3515 produces a comprehensive range of footwear for distributors, brand owners, and bulk clients. Our production capabilities encompass all types of shoes and boots, ensuring every component—from the boot itself to the correct lace length—is optimized for performance, safety, and comfort.

Let us handle the technical details for you. Contact our experts today to discuss your custom footwear needs and benefit from our extensive manufacturing experience.

Visual Guide

Related Products

- Premium KPU Injection Athletic Style Safety Shoes

- Premium Wholesale Waterproof Safety Boots High Performance Protection for Industrial Markets

- Puncture-Resistant Velcro Safety Boots for Wholesale & Custom Manufacturing

- Customizable Anti-Smash Safety Boots for Wholesale & Private Label Manufacturing

- Wholesale Slip-On Safety Boots Manufacturer - Custom Puncture-Proof & Steel Toe

People Also Ask

- What are the steps for cleaning hiking boots before waterproofing? The Essential Pre-Treatment Guide

- How waterproof are mid-height hiking shoes? Understanding their limits and uses

- What are the pros and cons of backpacking boots? Essential Support vs. Weight Trade-Offs

- When is waterproof hiking footwear most beneficial? The Ultimate Guide for Trail Conditions

- What are the advantages of hiking boots for backpacking or carrying heavy loads? Superior Support & Protection

- What factors should be considered when choosing hiking shoes for comfort? Find Your Perfect Fit for the Trail

- How do waterproof and non-waterproof hiking shoes compare in terms of weight and cost? Choose the Right Footwear for Your Hike

- What are the specific advantages of waterproof hiking boots? Keep Feet Dry & Safe on the Trail