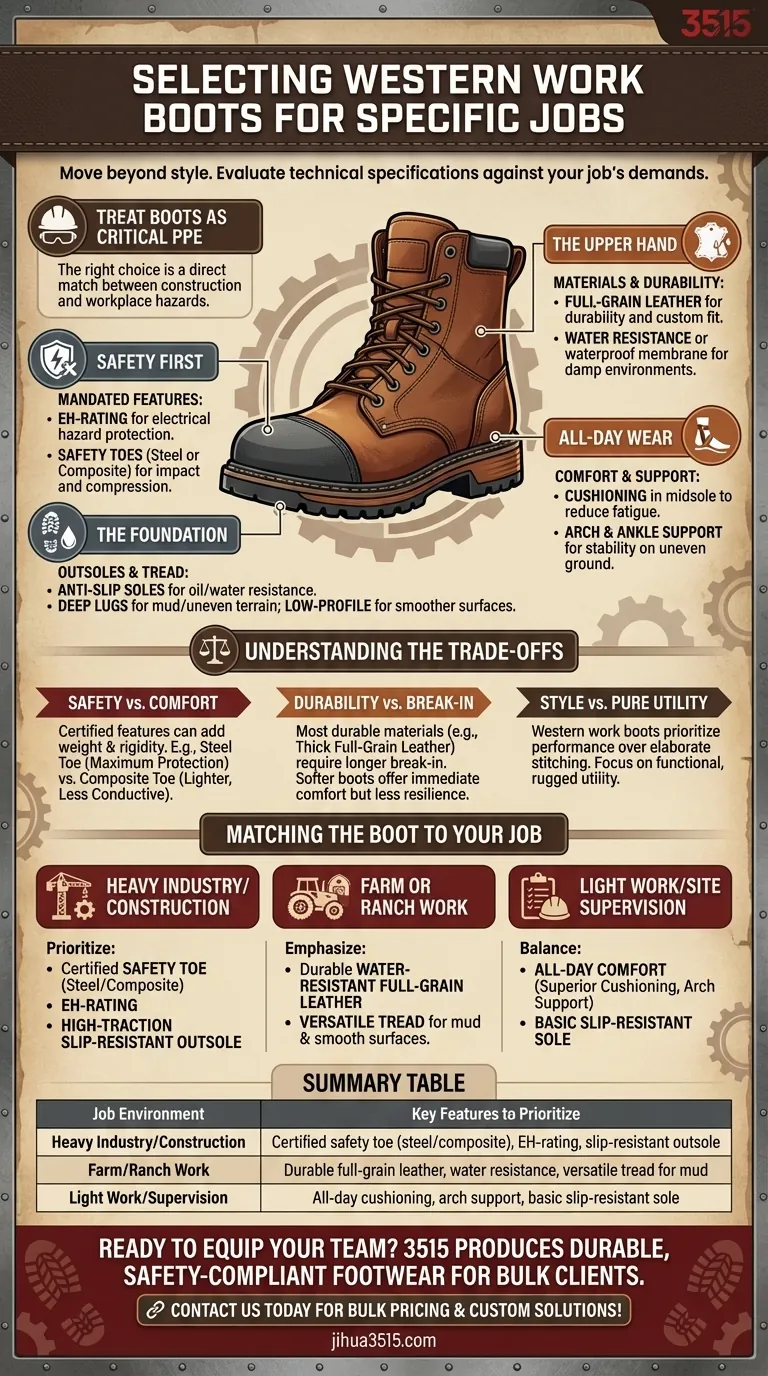

To select the right Western work boot, you must move beyond style and evaluate the boot's technical specifications against your specific job's demands. The key considerations are mandated safety features like safety toes or electrical hazard ratings, the environmental conditions you face daily, the quality of materials like leather and sole compounds, and the boot's internal comfort and support systems. Proper fit is the final, non-negotiable element for all-day performance.

The most effective way to choose a Western work boot is to think of it not as a piece of footwear, but as a critical piece of personal protective equipment (PPE). The right choice is a direct match between the boot's construction and your workplace's unique hazards and conditions.

Deconstructing the Western Work Boot

Understanding the individual components of a Western work boot and their function is the first step toward making an informed decision. Each element serves a purpose directly related to safety, durability, or comfort.

Safety First: Mandated Features

Many job sites require specific safety certifications. An EH-rating, for instance, indicates the boot provides a secondary source of protection against accidental contact with live electrical circuits.

Similarly, safety toes are a common requirement to protect against impact and compression. While steel is traditional, composite toes offer a lighter-weight, non-metallic alternative that doesn't conduct cold.

The Foundation: Outsoles and Tread

The outsole is your primary point of contact with the ground, making it critical for stability. Look for boots with anti-slip soles specifically designed to resist oil and water, which is essential for environments like machine shops or wet concrete floors.

The tread pattern also matters. Deeper, more aggressive lugs provide superior traction in mud and on uneven terrain, while a lower-profile tread may be more comfortable and appropriate for smoother surfaces.

The Upper Hand: Materials and Durability

High-quality boots almost universally use full-grain leather for their uppers. This material is exceptionally durable, breathable, and conforms to your foot over time for a custom fit.

For wet environments, consider boots with built-in water resistance or a waterproof membrane. This feature is crucial for keeping your feet dry and comfortable during long shifts in damp conditions.

All-Day Wear: Comfort and Support

Modern work boots incorporate advanced comfort features. Look for adequate cushioning in the midsole to absorb shock and reduce fatigue, as well as robust arch support to maintain proper foot alignment.

Good ankle support is also vital, especially when working on uneven ground. The structure of the boot should help stabilize your ankle to prevent sprains and other injuries.

Understanding the Trade-offs

Selecting the perfect boot always involves balancing competing priorities. Being aware of these trade-offs will help you make a more realistic and effective choice.

Safety vs. Comfort

Certified safety features, while essential, can add weight and rigidity. A steel toe, for example, offers maximum protection but is heavier than a composite toe and can feel less comfortable in extreme temperatures.

Durability vs. Break-in Period

The most durable materials, like thick full-grain leather, often require a longer break-in period. A softer, more flexible boot might feel better out of the box but may not offer the same long-term resilience.

Style vs. Pure Utility

While Western work boots offer a distinct style, they often feature less elaborate stitching and a more rugged appearance than traditional cowboy boots. This focus on function means prioritizing performance features over purely aesthetic details.

Matching the Boot to Your Job

Use your primary work environment as the ultimate guide for your selection. Different goals require you to prioritize different features.

- If your primary focus is heavy industry or construction: Prioritize certified safety features like a safety toe and an EH-rating, paired with a high-traction, slip-resistant outsole.

- If your primary focus is farm or ranch work: Emphasize durable, water-resistant full-grain leather and a versatile tread that can handle both mud and smoother surfaces.

- If your primary focus is light work or site supervision: Balance all-day comfort, like superior cushioning and arch support, with a basic slip-resistant sole.

Ultimately, the right boot is the one that allows you to perform your job safely and effectively without a second thought.

Summary Table:

| Job Environment | Key Features to Prioritize |

|---|---|

| Heavy Industry/Construction | Certified safety toe (steel/composite), EH-rating, slip-resistant outsole |

| Farm/Ranch Work | Durable full-grain leather, water resistance, versatile tread for mud |

| Light Work/Supervision | All-day cushioning, arch support, basic slip-resistant sole |

Ready to equip your team with the perfect Western work boots?

As a large-scale manufacturer, 3515 produces a comprehensive range of durable, safety-compliant footwear for distributors, brand owners, and bulk clients. Our production capabilities encompass all types of safety boots and work boots, tailored to meet the specific demands of industries like construction, farming, and light industrial work.

We ensure your workforce is protected with features like certified safety toes, EH-ratings, and slip-resistant soles, all while providing the comfort needed for all-day wear. Let us help you source reliable PPE that boosts productivity and safety.

Contact us today for bulk pricing and custom solutions!

Visual Guide

Related Products

- Safety Footwear Wholesale Manufacturer for Custom OEM/ODM Production

- Custom OEM Training Shoes Wholesale Manufacturer Durable & Breathable

- Wholesale Safety Footwear Manufacturer for Bulk & Custom OEM Orders

- Durable Rubber Sole Outdoor Shoes Wholesale & Custom Manufacturing

- Wholesale Durable Safety Boots | Custom Steel Toe & Puncture-Resistant Manufacturing

People Also Ask

- Why do fire boots have a heel? The Critical Safety Feature for Firefighters

- What insulation level is suitable for moderate cold weather? The 400g Standard Explained

- How did engineer boots transition from workwear to fashion? From Locomotive to Runway

- Are composite toe boots required by OSHA? Focus on the Right Protection for Your Team

- What is molded or direct attach construction in work boots? A Guide to Superior Durability & Water Resistance

- What are the main characteristics of RB (Rubber) as a material for work boots? Unmatched Durability & Slip Resistance

- Can work boots be used for hiking? Weighing Protection vs. Performance for the Trail

- How does the size of women's work boots compare to men's? The Key to a Safe, Anatomically Correct Fit